Connecting two air compressors together can provide you with a solution to a lack of airflow supplying your higher-demand air tools. The process can be fairly straightforward if you have the right equipment at hand and certainly beneficial.

I will present to you all the relevant information on why you might want to connect two air compressors together and how you can do this, with some beneficial YouTube demonstrations and reader questions and answers to follow!

Table of Contents

- Why Connect Two Air Compressors Together?

- How to Connect Two Air Compressors Together?

- Adjusting the Pressure Switches

- Key Considerations

- Useful Youtube Demonstrations

- FAQs (Frequently Asked Questions)

- Reader Questions & Responses

Why Connect Two Air Compressors Together?

It’s possible your air tool has a greater demand for compressed air than your air compressor can deliver, therefore you will be using the air tool at a greater rate than the compressor can actually supply to it.

And, even though the air compressor is running, it cannot keep up with the demand of the air tool and so the tank pressure will keep dropping until there is not enough compressed air to run your air tool.

To use this higher-demand air tool, you will need a bigger compressor OR you can connect two compressors together to the same airline that feeds to the tool to have a CFM increase (cubic feet of compressed air per minute).

If you were to add another compressor that has the same CFM, brand, and model then you could double your current air compressor CFM rating without adding any control complexity. Essentially running a dual air compressor or running 2 air compressors in tandem.

This method of connecting two compressors for more CFM in compressor pumping the system, whilst also enabling a higher CFM at the air compressor tank/air pressure regulator outlet.

You can also connect two compressors of different CFM, make and model which will allow you to achieve greater CFM. For example, you could combine an air compressor with 15 CFM with a compressor with 10 CFM and be able to achieve 25 CFM.

I have included YouTube demonstrations of both cases further down this page, if you require more information on Best Ways To Increase CFM On An Air Compressor – SCFM please visit the page I’ve written on this topic!

How to Connect Two Air Compressors Together?

If you have two air compressors and you’re now wondering how you can connect them together, simply connect a hose from the discharge coupler of their tanks on each to a tee manifold that will have a third connection where you can install a hose that will head towards your desired air tools. Use quick connect fittings where possible for ease of disconnecting and reconnecting the system when required. I’ve found a T-style manifold available on Amazon that would be ideal for this connection and can give you a better idea.

- 2-Way air MANIFOLD and splitter with (2) 1/4-inch brass 6-ball couplers

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

It’s important when plumbing this setup to include check valves between both air compressor tanks and the tee so that air can flow out of the air compressor and not flow back to either or both compressors.

This ensures that if one compressor is pumping and the other is not, the air being pumped from the working compressor cannot flow across and down the line to the other compressor and out its unloader valve.

If a sufficient amount of air is being drawn, both air compressors will cycle on working in parallel with all the air being compressed allowed to flow out the check valves and down the common line to the air tool. So, two airflows are combined into a single flow.

Installation of check valves won’t be difficult as they generally have arrows on them pointing in the direction of the flow. For more information on check valves, visit our Air Compressor Check Valve: How It Works, What It Does and Why It Exists guide!

The setup will look something like the schematic diagram below, where each compressor has a line connecting to a check valve and then further meeting at a tee before leading out to your air tool.

This setup applies to both industrial and home applications and is simple to conduct! Be sure to insert an air filter of some sort from the line after the T-manifold before reaching your air tool. This is important to filter out any particulates or contaminants that are in your air, which may include water vapor, oil, dirt, or rust. Visit our Compressed Air Filtration Guide – Types of Filters & Their Purpose to make an affirmed decision on what filter is best for you!

Adjusting the Pressure Switches

If you have air compressors that are the same make, model, and size then their cut-in and cut-out pressures should be set the same on their pressure switches so you may have no synchronizing issues to deal with! This will allow the air compressors to work approximately the same amount, depending on the tool’s requirements of air.

If you have a gap between the cut-in pressure on the two air compressor switches that are too big, you’ll find that only one of your compressors may be doing the majority if not all of the work. This compressor will be starting and stopping far more frequently than the other which will lead to premature wear leading to increased maintenance requirements and potentially a shorter life span.

Ideally, you should set both air compressors to the same cut-in and cut-out pressures in order to achieve the full potential CFM of the combined system. However, not in all cases will you actually need both compressors running as just one compressor will have sufficient air to power your tool!

So, I would advise adjusting one compressor to have a cut-in and cut-out pressure around 5 PSI lower than the other. As the air demand exceeds the capacity of one of the air compressors, this minimal 5 PSI pressure differential would allow the other compressor to start almost immediately.

Note: in most cases, your air tools air demand will only need the capacity of one air compressor therefore this one air compressor will be doing most of the work. This brings me to the point of adjusting the pressure switches periodically on both compressors so that they switch turns at being the primary and secondary.

Key Considerations

When connecting two compressors together, whether they’re the same (dual) or different, you must consider a number of factors before doing so. Both are great for continuous air tool use applications as the air compressor system has a higher CFM and is also suitable for intermittent uses, especially in cases where certain air tools require greater CFM than just one of your air compressors can supply.

If you haven’t got a continuous demand for higher CFM, connecting two air compressors together may be a rather drastic approach. You may be better off purchasing an additional air tank rather than a full compressor to connect two air tanks together, given that you’re demanding short periods of continuous use – and thereafter save some money!

Connecting two together may not be as cost-effective as buying brand a new compressor that is a suitable size to deliver your required airflow. This could be a cost-effective solution however if you’re using a spare compressor or borrowing one from a friend or neighbor for your higher-demand air application that is maybe a one-off or not needed so often.

You must consider the duty cycle of the air compressor to ensure you size your new one correctly. For more information please visit our How To Size An Air Compressor – What Size Compressor Do I Need? guide.

Useful Youtube Demonstrations

Here are some useful air compressor combination videos that hopefully can be of great help to you!

This first YouTube demonstration shows you 2 different air compressors of CFM, make and model combined together.

The second video demonstrates a dual air compressor setup (2 of the same air compressors).

FAQs (Frequently Asked Questions)

Yeah. To do so, simply plug an airline into each coupler at the discharge of each compressor’s air tank and connect them to a T-manifold. Connect another line from the T-manifold to your air tool and away you go! Be sure to include check valves between each air compressor and the manifold so that air is unable to flow back to either compressor.

Yeah, connecting two compressors together onto one line to the air tool will provide you with enough airflow from the two compressors to meet the high-demand requirements of your air tool.

The term “Daisy Chain” would normally apply to taking the output of one compressor and running it to the input of the other compressor. I’m not sure this is what you’d want to do, but you can connect both outputs of the compressors to a common tee, and from here have an additional hose connecting to your tool!

Yes, adding a second air compressor pump to your system will increase your CFM. You will now have a system capable of providing the primary compressors CFM + the additional secondary compressors CFM. If they have the same CFM then you will have double the amount available. Another example is if the primary compressor has 5 CFM and the secondary has 10 CFM you will have 15 CFM available after adding the second air compressor to the first.

Additional CFM reading:

- SCFM Vs ACFM Vs ICFM – What’s The Difference? Converting & Calculating

- Best Ways to Increase CFM On Air Compressors

- How to Calculate CFM of Air Compressors

- CFM Pipe Size Chart

- SCFM vs CFM for Air Tools & Air Compressors Guide to Compressor Ratings

- What Is CFM and What Does CFM Mean on An Air Compressor?

- Air Compressor Size For Spraying Stucco & Plaster

- Does a die grinder require low or high CFM?

- Speedaire 4B247 swapped with 2Z499 and its effect on CFM?

- 20 CFM Air Compressor – Buying, Hiring, What Can They Run?

- Air Compressors That Produce 500 CFM And Above

- CFM SCFM PSI Compressor Flow Issues

- Ingersoll Rand Type 30 model 242 HP and CFM?

- CFM rating of Black Max compressor

What size air compressor:

- What Size Air Compressor Do I Need? How to Size An Air Compressor

- What Size Air Compressor Do I Need For Impact Wrench?

- What Size Air Compressor For Sander?

- What Size Air Compressor For Sandblasting?

- What Size Air Compressor For Framing Nailer?

- What Size Air Compressor For Air Hammer?

- What Size Air Compressor For Air Ratchet?

- What Size Air Compressor for Car Detailing?

- What Size Air Compressor for Truck Tires?

- What Size Air Compressor For Nail Gun

- What Size Air Compressor for Painting Cars?

- What Size Air Compressor Do I Need for Spray Painting?

- What Size Air Compressor For Staple Gun Or Upholstery Air Stapler?

- What Size Air Compressor Do I Need For A Die Grinder?

Reader Questions & Responses

Connecting two air compressors together?

Question

Can I connect two air compressors together to increase air capacity?

Response

Simple answer…. yes!

You need to tee the outputs to your shop air. And you need to put a check valve in each output line from the compressor before that line gets to the tee.

You will want to adjust the pressure switch settings periodically so that the same compressor isn’t coming on all the time, and the other sitting idle if that’s a concern for you.

Essentially, once the air demand drops the tank pressure to cut in, the compressor will start. If demand continues to drop the tank pressure, with the right switch settings, the second compressor will come on to add more air to the lines too.

Connecting 2 Compressors to Get Combined Pressure and Volume.

Question

In order to achieve the desired pressure and volume for our pneumatic equipment, I need to inter-connect 2 compressors.

I need advice on how to go about doing it and need a couple of questions answered:

1) Is it necessary that both compressors share the same specs?

2) Will the resultant pressure and volume be a sum of both compressors?

Response

Both are good questions, and both are covered extensively on the pages of this site already.

Answer to question #1 – no.

Answer to #2 – no. If each compressor puts out 100 PSI, your downstream airline will not see 200 PSI. What you will do is increase the available compressed airflow at the pressure the system needs.

Both compressors will plumb to the same air main to your plant.

Both air compressors will have a one-way or check valve in their lines before the two lines connect to the single main.

In order for one compressor not to be the one that’s always on first, undergoing greater wear, periodically change the pressure switch settings so that the alternate compressor comes on first.

Have a look at Plumbing, Add A Tank, Add a Compressor, and other pages on this site for more details.

Manifold 2 Air Compressors

Question

I have 2 industrial air compressors. Both are 220v 3 phase with one being a 7 hp, the other a 5 hp. I am wanting one compressor to be the primary while the other acts as the secondary to kick during high peaks when compressor 1 can not keep up with peak demand times.

I know there are a couple of different ways these can be plumbed together but, am not certain of the best or most recommended way to pipe these up.

Suggestions and experience would be greatly appreciated.

Response

I get this type of question about putting two compressors together to increase flow and or have a backup for greater demand, quite frequently.

The frequency of the backup compressor switching on will be predicated on the pressure switch settings of that compressor. If you have the cut-in pressure just below the cut-in pressure of the primary compressor, then the secondary will only come on when the pressure level in the primary tank falls below the normal cut-in, suggesting that even though the primary compressor is running, it cannot supply enough air. At which point the secondary compressor would start too, even though the primary would be running as well.

Both compressors can be plumbed to the same main. Assuming that both lines go to a common tee, and the outport from the tee goes to the air mains, ensure that you have a check valve in the line from each compressor to the tee so that air from one compressor doesn’t backflow and out the unloader valve on the secondary.

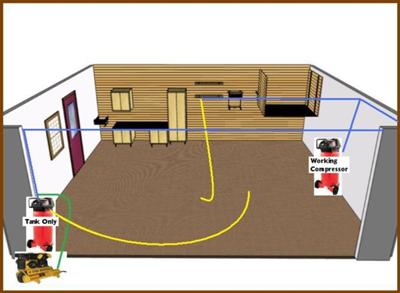

Garage Air Lines, Secondary Receiver, and Combining Compressors.

Question

First, yes I am a DIYer and new to the understanding of compressed air. At home, I have a working older Craftsman 110v/5hp oil-free 20-gal compressor that claims to put out around 5 CFM @ 90 PSI but is woefully underpowered. I also have a gas-powered 5.5hp 9-gal wheelbarrow compressor that supposedly puts out 12.1cfm @100 that I will be using at my warehouse that has no a/c power.

After reading up on this site and others, I have a plan that I would like some feedback on. See the attached picture. I picked up a broken 26-gal compressor to use the tank as an additional receiver. I am considering buying the Complete Garage Air Kit from Harbor Freight to plumb as pictured. My questions are many: 1.) Can the additional receiver be as far as 50 feet from the electric compressor? 2.) Can I add the gas-powered compressor near to the additional receiver to use in combination with the electric compressor? 3.) Will I actually approach 17cfm with this combination?

Response

Good to hear from you. The short answers to your questions are:

1) Yes

2) Yes

3) Doubtful

You can’t run a 5HP compressor with 120-volt power. There’s not enough juice there to power a 5 HP motor properly. Underpowered it is, for sure.

As to addressing all the implied questions, let me say that all of the answers you seek are on the pages of this site, and it doesn’t make a whole lot of sense to me to re-type all of the existing info here.

Please start with the Plumbing page, and go from there. There’s info on adding a tank, adding a second compressor, and so on. Use the site map page to zero in, and/or the search engine on that page.

I envy you for your proposed setup.

Setting Up A 2 Compressor System

Question

I have 2 similar compressors, I want to have them set up so when the primary gets behind and can’t keep up with demand the other one comes on and helps it out at peak usage times. Do I need some special switch to do this?? can someone give me an example of how this works correctly?

Response

Nope, no special switch. You just use what comes with the compressors, with a bit of creative compressed air plumbing. Have a look at the TWO COMPRESSORS page linked from the site map.

Connect 2 Air Compressors Together On the Same Air Line

Question

What are the Precautions to Connect 2 Air Compressors Together On the Same Air Line?

Compressor Model: Sullair 5500

Air pressure: 120 psi

Response

First off, though it was a nice photo, I didn’t think it suited the site or the question, so I deleted it.

Second, I’ve written about this issue on a number of pages. Why not visit this page for info on plumbing two compressors together?

Adding Compressor

Question

I have a 50-hp compressor in my air system.

I need to increase capacity.

I am thinking to add another 50 hp compressor.

How would the new compressor connector be?

Can it be connected before the current receiver tank?

Do I need a second receiver?

Response

Howdy. Since all your questions are already answered in great detail in the pages already on this site, the pages to do with plumbing, adding a tank, a second compressor, compressor water, etc. linked from the navigation bar and site map would you please have a read of the info already here, and if you have questions after about items I don’t cover, I would be happy to answer them.

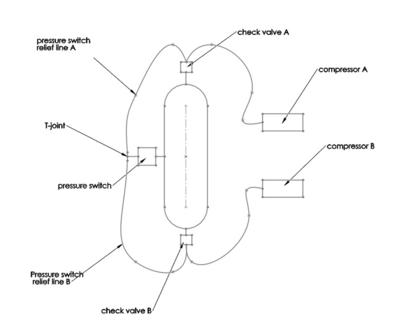

Dual Air Compressor Setup

Question

Hi there,

Is it possible to connect two small air compressors?

Plumbing dual compressors

I’d like both to be operated by one pressure switch with separated discharges on the same tank accompanied by 2 check valves sharing the same relief line of the pressure switch?

Doable?

Response

Anything’s possible, I guess.

If both pressure switches “saw” the same tank pressure, if they both had the same cut in and cut out, they may cycle OK.

Not understanding why you would want two discharges? Why not one, to a manifold, into which you could plug as many couplers as your manifold had spaces?

“accompanied by 2 check valves”, not between pump and tank, as then the pressure switches might not get a pressure reading from the tank.

Seems like an odd request. More details about why you need to do this might help.

Response

Sounds like you just want to share the air between two workers, but one compressor isn’t quite big enough for either worker.

Keep it simple. Just tie the two tank outputs together, and run that to a manifold with two outputs.

No need for check valves or any of that.

If they both try to start at the same time and that’s too much for your power supply, just adjust the cut-in on one of them a pound or two lower than the other, and they’ll power up in sequence.

If you want to even out the wear on them, then reverse the cut-in settings every so often.

If that’s not what you want, what Bill said…

Question

Hi again

I think my English is not the best, nor my pneumatic skills. I think my drawing might help with what I try to mean!

(Graphic has been added to the top of this thread – Moderator)

Response

As mentioned before, I think we understand what you wish to do, and what you propose in your drawing would work, but based on what we know, it is not necessary, and overly complicated.

The question remains, why do all that? Are you trying to save money on the pressure switch?

Please give us an idea of what you are starting with. For example, a couple of bare compressor pumps with no tank or controls? Or a couple of complete stand-alone compressors? Or is that to be determined?

Question

I only have x 2 small compressors so far (piston-150watt each, used) and intended to be used on a

50ltr air tank (which I haven’t bought yet, with all the additional components required).

I was told that one alone is too small for the desired capacity.

No, I don’t try to save money on a secondary pressure switch, I just thought of making them start/stop simultaneously, as one, because of the low HP output.

I used to work on sheet metal fabrication and finally decided to make a sheet metal-enclosed air compressor-vertical box to add to my home workshop.

Response

OK, I thought that might be the case.

Go here:

then look at the reviews – scroll down to the one with three compressors. Check out the photo.

That’s how to do it. The manifold on the floor at the right is an off-the-shelf thing, but you can use whatever you want, and the combined output on the single hose can be used directly, or eliminate the hose and connect it directly to your proposed tank.

You may or may not need separate power connections as the author has done. You really don’t want two or more compressors coming on at the same time as that will tend to strain the electric service.

The only caveat is that the regulators should either be removed or left wide open. If you don’t follow that, then the regulator with the lowest setting will bleed off air to get to its setting.

The scheme applies to as few as two up to however many compressors you need. You don’t need extra check valves as they are self-contained on the compressors.

Feel free to ask if I left anything out.

Question

Hi there,

I saw your link and it did help, as also generated a new approach.

Thanks all for your answers and guidance!

Response

Cool. Thanks for the update.

Send pix when you get your setup going, please.

Have fun.

If you have any questions regarding connecting two air compressors, please leave a comment below, with a photo if applicable, so that someone can help!