Hey! This site is reader-supported and we earn commissions if you purchase products from retailers after clicking on a link from our site.

Why is it a compressor will not build pressure? Does the following describe what’s happening, or rather, what’s not happening, on your compressor?

The motor runs and runs. The pump sounds like it’s operating, but the air pressure in the tank is not rising in pressure at all. Or, the pressure in the tank rises to a certain pressure level and then the pressure stops rising, even though the compressor continues to run and run.

Leaving you wondering why your compressor isn’t quite working how an air compressor should work!

I will provide you with the most common reasons as to why my air compressor is not building pressure, and the severity of them, and provide you with ways to check each one.

Table of Contents

- Why Is My Air Compressor Not Building Pressure?

- Why Is My Air Compressor Not Building Pressure? Most Likely Reasons

- What to Check When the Air Compressor Will Not Build Pressure?

- FAQs (Frequently Asked Questions)

- Additional Reading

- Reader Questions and Responses

Why Is My Air Compressor Not Building Pressure?

The air compressor is really a pump driven by an electric motor, or perhaps with a motor driven by other fuel types like gasoline or diesel.

The part that actually compresses the air is often referred to as the pump, or compressor pump.

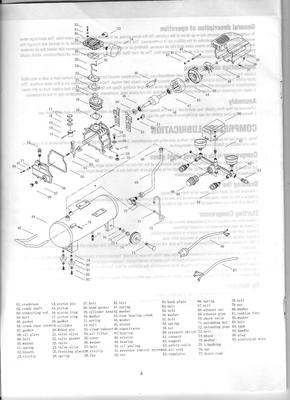

In the photo above, part of what’s missing is the pump head, which will contain an intake port. This pump is also missing the valves or valve plates which open and close depending on whether the pump is in the intake or compression cycle – you can see those below.

On all air compressors, the pump pulls in free air from the atmosphere through an intake valve. That intake port on the pump typically has a filter on it to keep dust out of the pump. The pump is then supposed to drive the air it takes into the tank, and in so doing increase air pressure in the compressor tank.

Different styles of air compressors, reciprocating versus rotary screws, for example, accomplish this with different methods, yet they pretty much all do the same thing, suck in air from around the room or through an outside air intake and drive that air into a tank to build up pressure.

When a compressor pump is driven by a properly working motor, and the pump is cycling, so why does the air compressor run but doesn’t build pressure in the tank? Next comes the most likely reasons.

Why Is My Air Compressor Not Building Pressure? Most Likely Reasons

- Compressor intake valve failure

- Compressor pump pressure valve failure

- Compressor gasket failure

- Compressor piston seal failure

- The tank check valve is compromised

The most likely reasons for your air compressor not building pressure are those 5 listed above.

Compressor Intake Valve Failure

If it is the intake valve that has failed, then the compressor will draw air in on one cycle, but then that air will blow right back out of the intake valve – the valve into which air from the compressor intake filter flows – and out of the pump again when the piston is in the compression stroke.

Air always takes the route of least resistance so a little of that air may actually be entering the tank, but then more flows out of the valve rather than down into the tank, which is why the compressor can sometimes reach a certain tank pressure beyond which it won’t go.

How to Check if the Compressor Intake Valve Is Failing

Remove the intake filter and feel if the air is moving in and out of that opening while the compressor is running. Be careful as the pump itself can become very hot.

If air is huffing back out of the intake valve port your intake valve is suspect. For most of us, a failed reed/flapper valve(s) means a trip to the compressor repair shop as it will mean tearing down the compressor pump to try and identify the failure, and then the search will begin for compressor parts.

Sometimes replacement valve plates are not available. That being the case, some clever compressor owners have made their own from spring steel. See the sitemap page under troubleshooting for links to pages about making your own reed or flapper valves for compressor pumps, and also about making your own gaskets too, since almost invariably if a compressor pump head is disassembled, some gasket damage will occur.

Compressor Pump Pressure Valve Failure

If it is the pressure valve or pressure switch in the valve plate that is the source of the problem, air will flow into the tank through the pressure valve on the compression stroke, but then be drawn right back out of the tank as the piston cycle to try and draw more air in through the intake valve.

Again, air always follows the path of least resistance, and if it is easier for the air in the tank to flow back out through the damaged or failed pressure valve than being drawn into the cylinder via the intake valve, then that is what the air will do.

The Pump Valves

Reciprocating air compressors have valves that allow air to enter the cylinder area when the piston is moving down, and allow the air to be directed into the tank line when the compressor piston is on the compression stroke.

Other styles of air compressor pumps have valves too. Low-cost reciprocating compressors typically have low-cost reed or flapper-type valves which, at least according to the number of persons who report valve issues on this site, don’t seem to last very long.

If either the intake valve or pressure valve fails (breaks or fails to seat properly due to debris build-up) then your compressor will run all day and never build very much pressure in the compressor tank. The valve problem may also not appear until a certain tank pressure level is reached, at which point, the valve problem manifests itself by the compressor continuing to run, but no further buildup of air tank pressure occurs.

Once you have eliminated all other reasons why the compressor runs but doesn’t build pressure, it may be time to tear down the pump and examine those valves.

Compressor Gasket Failure

The flow path of the intake air inside the pump head is often only separated from the flow path of the pressurized air to the tank by a gasket.

Gaskets do wear out. Good quality gaskets cost more money than cheap ones, so it stands to reason that you probably are not getting top-quality parts – whether gaskets or other components – in a $40 DIY-type air compressor.

It is possible that your compressor is working fine, but as it is cycling, the air is flowing back and forth across a failed gasket inside the pump instead of being forced into the tank.

How to Check if the Compressor Gasket is Failing

Sometimes air may flow into the tank until the pressure in the tank is high enough to force an opening through a normally sealed gasket in the pump head. You need to have the compressor pump torn down to check this out.

If you are tearing the pump down it is advisable to change both the valve plate and all the gaskets, as taking the pump apart will likely damage the gaskets so they will not seal when the pump is rebuilt.

Compressor Piston Seal Failure

The compressor pump sucks atmospheric air through its intake valve and has a filter that aims to restrict dust particles from entering the compressor tank. The rings on the compressor pump act as seals, which prevent excess oil from being able to flow into the compressor’s cylinders.

However, another common issue for the air compressor not building enough pressure might be from its pump’s defective rings. If the rings are defective, the pumps will lose pressure and compression strength. This can also reduce the pump’s efficiency to optimize the production of compressed air.

How to Check if the Compressor Piston Seal is Failing

It’s worth checking the piston seal and rings at the same time. Normal checks on air compressors conducted by technicians include rebuilding or replacing the pumps with worn seals to confirm that both pumps and rings are operating efficiently, the valve plate seal might then be the source of the leak.

An alternative way of detecting pressure loss from piston rings is when air or oil is coming out of the oil fill tube. Regular inspections on air tube fittings, ensuring they are firmly attached to their rightful positions must be conducted. It is possible, however, that the piston ring failure causes other components inside the cylinder to be damaged.

If the piston cycles with worn-down rings, metal-to-metal contact is quite inevitable. This is a very common cause of pressure loss within the combustion engine with a stuck air compressor piston. This fault makes it relatively easy to notice a lack of pressure build-up, as pressure will not be building up from the gauge.

Tank Check Valve is Compromised

The check valve is an important component that restricts compressed air from back-flowing into the pump.

When this component is defective, the discharge head of the pump will receive a high pressure of air. It will affect the pump’s motor might and stop it from restarting anytime the tank is full. However, the motor will start when the air tank is empty.

How to Check if the Tank Check Valve Is Failing

If your air tank has a defective check valve, there will be air leaks from the unloader. So you must run another spot to check carefully on the unloader valve.

The unloader valve should burp or hiss out a bit of compressed air when the compressor reaches its cut-out pressure and the compressor stops. The unloader valve should not have air bleeding out of it all of the time. If that is happening, this may be the reason that your air compressor cannot compress air past a certain pressure level as it is losing air as fast as it can compress it.

If the unloader valve is leaking, you need to double-check it but first, check your tank check valve. A poorly seated or failed tank check valve is frequently the cause of what appears to be an unloader valve leak as the air will bleed out of the unloader from the tank as long as the compressor is NOT running. Try to confirm if the air leaks continue when the pump is inactive, and replace the check valve immediately.

Cost Summary of Air Compressor Not Building Pressure

| Reason | Severity (low-mid-high) | Cost Implications | Cost Estimate |

|---|---|---|---|

| Compressor intake valve failing | Low | A replacement valve + 1-hour labor | $120 |

| Compressor pump pressure valve failing | Low | A replacement valve + 1-hour labor | $120 |

| Compressor gasket failure | Mid | A replacement gasket of good quality (more costly) + 1-hour labor | $150 |

| Compressor piston seal failure | Mid | Replacement piston rings + a good few hours of labor to disassemble the pump | $300 |

| The tank check valve is compromised | Low | A replacement check valve + 1-hour labor | $120 |

Above is a summary table of the most likely reasons for your air compressor not building pressure with the severity of each and the cost implications provided.

The costs are estimated on a rough labor cost of $80 and then the cheapest parts available on Amazon. It’s important to note that if you wish to buy the best parts your costs will increase and that if you can do the maintenance yourself, you will of course save labor costs.

Low severity indicates a quick fix and your air compressor will be back up and running with no subsequent issues. High severity indicates a longer fix, with damage done to other components within the system.

What to Check When the Air Compressor Will Not Build Pressure?

Okay, so I’ve provided you with the most likely reasons for your air compressor not building pressure. Now, let me provide you with a more general check you can conduct and some other potential reasons.

Compressor Valve or Gasket

The air compressor reed or flapper valves (also known as the intake and pressure valves, or suction & discharge valves) are a common cause of why an air compressor will not build pressure.

The image below shows the valve plates (top of the photo) and reed valves (bottom left of the photo) from one smaller air compressor. It also shows the gasket (bottom right in the photo).

If the compressor valves or gaskets are what the pump problem is, then it will be necessary to disassemble the pump to repair that problem. The issue is in determining whether it is the valves that are the problem.

One clue to a prospective valve problem is if the air is exiting the intake port when the compressor is cycling. Removing the intake filter briefly will help determine this. If air is escaping there it’s a pretty good bet that the intake filter flapper is damaged in some manner.

Pressure Side Reed Valve or Pump Gasket

If it’s the pressure side reed valve, or if the pump gasket is creating the problem, that’s harder to diagnose, yet the symptoms are the same. Either no pressure builds in the tank or the tank pressure increases to a certain point and then stays there, regardless of how long the compressor runs. That might even result in the compressor shutting itself down if the motor overheats.

The only real check here is to pull the pump head off and examine what’s what. If a reed valve is damaged, that’s usually pretty obvious. If the pump gasket is weakened and blowing open at a certain pressure, that’s harder to see.

The solution to the latter is to replace the gasket regardless of whether the reeds are damaged or not.

Compressor Power Supply

Do not underestimate the importance of a clean power supply and abundant power supply to the socket into which the compressor is plugged. Also, be aware of the size of the power cord that goes to the compressor.

If you are starving your air compressor of enough power supply, the motor will likely generate a certain level of pressure in your tank, and then not be able to exceed that pressure. Insufficient power reaching the motor will not allow it to work hard enough to build pressure against the increasing back pressure from the tank. A too-low amperage or too-small power cord could be causing the problem.

If you must use an extension cord to power your air compressor, make sure it is heavy enough to feed the compressor over the length of that extension cord. Look at the power demand of the compressor motor, and make sure the cord is heavy enough gauge to deliver that power over its length. It is much preferred that you plug the power cord that came with the compressor right into the socket and not use an extension cord at all.

If you must use an extension cord rather than a longer air hose (that’s the much-preferred option for supplying compressed air farther from a power outlet) Google “recommended wire gauge for electric motors” and ensure that the cord you wish to use is big enough.

Clean Compressor Power Supply?

Clean power also means that nothing else that might be powered by that same electrical circuit is trying to run at the same time your compressor is. Compressors will run best with a full electrical supply from a dedicated circuit, over the shortest electrical cord possible!

It’s difficult sometimes to get a socket to which nothing else is connected. If that’s the case for where you plug in your compressor, determine what else is on that circuit, and try to ensure nothing else is running, or going to run, when you are planning on using the compressor.

Does Your Air Compressor Leak?

If it does, let your compressor come up to whatever pressure it will. If the pressure reaches a certain level and then won’t go past that pressure level, then either turn it off or unplug it.

Listen while the compressor is off, and watch the tank gauge as well. What you are checking for is an air leak that you won’t be able to hear when the compressor is running. If the pressure in the compressor tank is dropping and nothing is using air the leak may be bleeding off enough air that the compressor can’t build tank pressure past a certain point.

Economics of Air Compressor Repair

Let us consider the economics of compressor repair for a moment, I provided a rough idea of the severity and cost implications in the earlier summary table.

I am astonished at how the price of air compressors has declined over the last decade. Not the high-quality industrial air compressor, but the smaller, DIY home-use compressor.

Changing out the reed valves on a small DIY-type air compressor will take about one hour of shop time, according to the repair depot I spoke to. What do they charge; $80 / hour, … more?

Then there are the parts themselves. Many of the DIY-type air compressors come from another country, and sourcing parts for these units is time-consuming if parts are available at all.

So, do you spend $100 or more dollars to fix your $150 compressor or not, considering that the replacement for it may be even less than what it cost when it was purchased? That’s a call you’ll have to make if your compressor begins to run without building full pressure. It may be worth investing in a brand-new compressor.

FAQs (Frequently Asked Questions)

Please note that an air compressor that will not start is not necessarily the same issue as one that will not build pressure. There is a page on this site dedicated to air compressors that will not start. A compressor starts properly but reaches a pressure level in the tank, and then it continues to run, and runs, and runs, but the pressure never goes any higher, if this is your compressor problem, here are some more things to check.

Usually, if an air compressor is taking longer to fill, it typically is either a piston seal problem, gasket failure, or an intake or pressure valve failure. These issues can be checked by following the information provided on this page.

To increase your air pressure, so that the air compressor kicks on sooner before the pressure drops too low. You can adjust the lower adjustment screw on the pressure switch by following these 4 simplified steps:

1. Remove the plastic cover over the pressure limiter switch

2. Locate the two limiter switches. Tun the upper limit adjustment screw to raise the limit

3. Turn the compressor on and adjust the screw until you reach your desired pressure on the gauge. To maintain this pressure- turn the lower limiter adjustment screw clockwise to raise it so that the compressor kicks on sooner.

4. Connect your tool and charge the compressor, test the limits you have set and make adjustments if necessary.

It is important to ensure you consult the manual provided by the manufacturer or contact them directly to find out what your upper-pressure limits are so that you do not exceed their safety limits.

To prime your air compressor you must add oil to both your receiver and the suction port of the compressor. It’s important to know the oil capacity of your compressor before starting, then begin with half being poured into the receiver and half into the suction port.

If you have an oilless compressor, you must fill the pump with fluid that acts as a coolant, to help prevent the pump from overheating. The fluid will help remove the air and stop the compressor from running dry, which may lead to mechanical seal failure or even serious damage to the pump’s components.

It can typically take anywhere between 2-5 minutes for an air compressor to build up pressure. It shouldn’t take any longer than this. The greater the CFM of your compressor the quicker the compressor can pump air into its tank. Also the larger your tank, the longer the time needed to fill it due to the increased volume.

If the compressor motor is still running after the air pressure in the tank reaches the normal cut-out air pressure level, then look to your pressure switch first as the source of the compressor problem.

If your air pressure in the tank is not reaching the cut-out pressure limit, the compressor cannot shut off and will keep running. You must look to the intake valve or an internal gasket leak as this possible source, visit our page Air compressor will not shut off for more information.

The pressure switch controls the air on an air compressor by determining how much air pressure is needed to run a pneumatic device that you wish to connect.

The pressure switch is the most basic and important setting on your compressor.

Additional Reading

We have a number of brand-specific pages available on our website which may include reader questions and responses specific to your air compressor brand:

- Bostitch Air Compressor Won’t Build Pressure

- Craftsman Air Compressor Not Building Pressure

- Husky Air Compressor Won’t Build Pressure

- Central Pneumatic Air Compressor Won’t Build Pressure

- Campbell Hausfeld Air Compressor Not Building Pressure

- Porter Cable Air Compressor Won’t Build Pressure

Reader Questions and Responses

Air Compressor Won’t Build Pressure

Question

My air compressor gets air from the motor but doesn’t put any in the tank.

Response

Mike, I have no idea what you mean when you say your compressor gets air from the motor.

Are you saying that the pump is pulling air into the intake, and you’ve pulled the line to the tank from the pump and are getting good pressure out of the pump?

Maybe you could take a moment to explain further, and add a photo or two of your compressor to help others help you?

Question

There’s good pressure coming from the hose. But it’s not building up in the tank

Response

Still puzzled, Mike.

If you’ve got good pressure in the hose, then your compressor can keep up with the demand of your air tool.

It is likely then, but I’m really not sure from what you’ve posted, that the compressor can supply the tool but if you are using the air tool, there is not enough air capacity to fill the tank at the same time.

Is that it?

What happens if you just run the air compressor?

Also, are you sure the tank gauge is working? What pressures are the two gauges showing; the tank gauge and the regulator gauge?

Montgomery Ward Compressor Won’t Build Pressure – Montgomery War Air Compressor Troubleshooting

Question

My low pressure air compressor is a Montgomery Wards brand 220v/1.5 hp 20-gallon model, with a Franklin Electric motor, a two-cylinder compressor, and a Kargard Industries tank. The date code on both the tank and the motor is 1972. Montgomery Ward Air Compressor

It seems my compressor has the same symptoms as a previous poster – it will not pressurize the tank above ~40 PSI. When the compressor is first turned on with the tank unpressurized, I can feel the cylinders sucking in air as they should; but as the pressure builds, more and more air is pushed right back out the intake valve. As with the previous poster, I disassembled the heads on my compressor to check the valves.

They’re just flat reed valves and appeared to be in fine condition, just a little dirty. I cleaned the valves, head, and ports copiously replaced the gaskets with new ones and reassembled them. But this did not solve the problem. Neither does change or even remove the air filter.

Bill, you mentioned something about a “check valve going into the tank” in regard to the previous poster’s problem. While his problem turned out to be a head gasket issue, it doesn’t appear that mine is, so I would like to know more about this check valve. What is its purpose, where exactly is it located, and how do I test it? Thanks for the help! -James

Response

Hello James. Thanks for visiting, writing in, and including a photo. It sometimes makes answering so much easier. If you look at your photo, see where the airline from the piston head turns and runs down to the tank on the left. Usually, the device that connects that airline to the tank opening is a check valve. Its purpose is to keep the air in the tank as the piston compresses it. The higher-pressure air flows down the line, through the check valve, and into the tank.

If this check valve isn’t seating properly or has failed completely, then air can’t stay in the tank. This may be an issue for your compressor. Best to make sure the tank is empty, and the compressor is unplugged, and then disassemble the fittings at the tank, and examine the check valve. It should seal the air in one direction. Reassemble after cleaning (if needed) and see if this makes any difference, OK?

Response

Sorry to barge in here, but I saw a lot of posters asking about the pump on Ward’s unit. That looks to me like a Champion pump, and parts are still available for those. They were used on a variety of brands (Speed Aire, for instance), and they made a million of them, much like the cast iron Campbell Hausfeld. Check with Grainger or Champion – I think you will find the parts. – Mark

Bambi Air Compressor Not Building Pressure – Bambi Air Compressor Troubleshooting

Question

I have a Bambi 75/250 compressor that’s worked perfectly for many years I lent it to a friend when he returned it it was laying on its side in the back of his truck he said it was working fine.

Now I have just gone to use it and it’s not making any pressure. I have checked the air adjustment valves still nothing could laying on its side be the problem as it is oil-filled.

Help would be much appreciated. My thanks, Mick P.

Response

Mick, oh my, that’s not good. I do believe that oil-lubed compressors in particular are meant to operate vertically, that is, with the sump at the bottom.

The oil sump of any compressor will, in time, have crud drop out of suspension and drop to the bottom of the sump. The amount and thickness may vary depending on how long the compressor has been in use. By turning your Bambi 75/250 compressor on its side, your friend may have caused some of that oil and crud to percolate into areas on the compressor where it shouldn’t be. Kind of like turning a car upside down. Oil and debris get where they shouldn’t go.

That it’s running is good. But it’s not making any air at all? How long have you run it without success in building air?

Response

Doug from s.d.ca asks, how long has the compressor been upright after you took it out of the truck and before you started it. The issue may clear itself in time, perhaps. Also, are you sure the tank drain valve is closed? And, does it sound normal when it’s running?

Response

Mick, I think that after a day or so of sitting upright, if it runs and there is no air built, first pull the pump-to-tank tube off the top of the piston head. Run the compressor. Any air out at all?

If there is some air, it could be that the tank check valve is fouled shut, and stopping air from entering the tank, is not likely, but possibly.

I think you’ll find that there is no air coming out of the pump head, and if that’s the case, I’m afraid it’s time to pop the top off and have a look. Valves may be fouled, etc.

What did you find if you opened up the pump?

UST Power System Model 110C Air Compressor Won’t Build Pressure Past 40 PSI – UST Power System Air Compressor Troubleshooting

Question

Hello,

UST Power System Model 1110c. Was working a couple of weeks ago and built-up pressure to 100psi. Today, it would only go to 40psi.

I disassembled the cylinder head and cleaned the flapper valves and checked they were seated correctly.

Slight increase in pressure to 50psi, but no more.

My suspicions are now leading to the piston rings. If I can find parts for this, the rings would be the next thing I would do.

But trying to find any online support eludes me at this point.

by Brian

Response

Brian, I have uploaded a photo of a UST Power System low pressure air compressor, though I cannot find an image of your specific model.

If yours is similar to this, then it has an oil fill tube and a vent. If your piston seals are leaking sufficiently that your compressor will not build pressure past 40 PSI, then you should be able to feel quite a flow of air out of the oil fill tube, as the cap is vented.

I rather suspect that you have a gasket that lets go at 40 PSI. That you disassembled and reassembled the pump made a change. Maybe you torqued the bolts down tighter, but you managed to hold off the leaking of the gasket, if that is what it is, for another 10 PSI.

Try a high-heat gasket sealer and see if that makes a difference, or make a new gasket from high-heat gasket material.

Also, empty the tank, remove, clean and replace the tank check valve.

Did it help?

Question

Bill,

Thanks for your quick comments. Yes, that is the exact model (You must have visited my garage today to get that picture)

Late last night I pulled the entire head to check the cylinder surface and rings. I did a minor honing and polishing of the cylinder wall. The rings appeared basically still new, as this unit has maybe a total of 3 or 4 hours of run time. Got it back in 2011. Double-checked the flappers, they were still clean from before and appeared to be eating well. While there I also polished both sides of the flapper plate.

Just a note that the tank is holding pressure, which leaves out the check valve. Though it does take a long time to just build 50psi at this point, about 5 minutes. Where before it would take 2 or three minutes to build to 100psi.

After reading the section “Compressor Won’t Build Pressure”, which gave me a couple of ideas in conjunction with your comments.

“Quick Check” Yes, there is some air coming out of the intake opening.

I will try your idea of sealing the gaskets tonight to see if that causes any changes.

Also, there is airflow coming out of the oil fill tube. Come to think of it, you can hear it and it seems to be more than I can remember.

Thanks again,

Brian Kerrigan

Response

You are welcome, Brian. Air out of the intake – that’s an intake valve problem

Lots of air out of the oil fill cap vent, that’s a piston ring or seal problem.

Question

Bill,

The main problem I found was, as it turns out, the gasket on the bottom of the flapper plate. While it was running, before it warmed up, I used the old soapy water method. Sure enough, it appeared air was coming from the gasket.

Replaced both upper and lower plate gaskets, in addition to honing the piston-cylinder and polishing the plate, it now fully gets up to full pressure in about 2 minutes. Faster than it did before.

The only issue now is the check valve has a crack. I think the check valve from a Powermate compressor may be the fit.

Thanks, Bill

Response

Brian, so very glad I was able to help with your compressor problem.

I think another good rule of thumb is if you disassemble the pump to get at the valves, then you want to replace the gaskets with new ones when you reassemble them to ensure that they aren’t part of the original problem.

Have a good one.

Compressor Runs But Won’t Build Pressure – Air Compressor Troubleshooting

Question

It seems to not have enough pressure from the pump to pressurize the tank.

I took the line off from pump to tank and put my finger over it and pretty much stopped the flow.

Are rings bad in the pump and are shot or something else?

Response

Howdy anonymous person…

Be good to know the make and model, as your air compressor problem may be common to one of those.

Your check of pulling the line off to the tank and seeing how much pressure is being generated is a good one. You have now pretty much isolated the compressor’s lack of pressure as being upstream of that point.

I would pull the intake filter too, and do the same check. Is it pulling air in strongly, or is it huffing air back out too? If huffing, that’s a sign that the intake valve is pooched.

If it is pulling air in, and the air is not being pumped out, yup, it could be a sign of cylinder piston ring wear, but then, you would be getting a lot of air out of the oil fill cap which is vented.

If that isn’t happening, and you are getting strong suction at the intake, my money would be on an internal pump gasket blown which is allowing air to flow around inside the pump from high pressure to low, but not down into the tank.

When you open up the pump, you might as well have a new valve plate and gasket kit, as both are, in time, worn items inside the pump.

Compressor Won’t Build Pressure – Air Compressor Troubleshooting

Question

My compressor operates fine but it won’t build any pressure while it’s running, I have no idea what’s wrong, need help, thanks

Response

Ted, it is always useful to know the make and model of an air compressor when trying to troubleshoot a compressor problem.

And, if your compressor is running, and it is not building pressure, then it sure is not “running fine”. 🙂

The first thing I would do is remove the intake filter. That eliminates that part as being the source of the problem, and at the same time, allows you to feel, while the compressor is running if the air is being pulled into the intake port.

Is it? Please post a comment here with what you found.

Air Compressor Does Not Build Pressure – Air Compressor Troubleshooting

Question

Why my air compressor will only pump up to 30 lbs of pressure?

When the pressure reaches 30 lbs. that is all it will compress.

The air begins to come out of the small vent holes on the oil fill plug and also at the intake air filter. Could this be reed valve problems?

Thanks

Tom F

Response

Tom, I’m guessing that when your air compressor tank pressure reaches 30 PSI, the air compressor keeps running, but no more pressure builds.

That being the case, have a look at the troubleshooting section, the page about why air compressors run but don’t build pressure. Some things there to check.

Offhand though, if you have air coming out the oil fill tube cap, and air coming out the intake, you’re likely looking at a new piston seal kit, a new valve kit, and a new gasket kit.

Pro Source Compressor Will Not Build Pressure – Pro Source Air Compressor Troubleshooting

Question

I have a 2HP Pro-Source compressor with a 13-gallon tank, distributed by Big Lots Stores. I’ve had it for about 4 years, looks pristine, only use it for inflating tires and blowing out my sprinkler system every fall.

This past fall the pressure will not rise past 25psi and the motor would keep running.

After shutting the motor I listened for any air leak sounds — no hissing and the pressure gauge showed pressure maintained for over 2 hours, so probably not a leak. Admittedly, I let the oil level get too low, then added 10W30 automotive oil to bring it up to level. Would that alone cause the problem?

After reading many of the posts on your website, I decided to check the reed valves.

I removed the head and found the valve plate. I was not aware of any gasket material (but leak-down after shut-off was so slow that I don’t think that would explain pressure not building.) The reed valves were not what I expected to see. I expected flexible strips that could “flap” over the ports.

Instead, I found very rigid “fingers” that could no way ever close over the ports. ??? Were those fingers just limiters, and did the flaps maybe vaporize from the extreme heat of running it with low/improper oil that’s why I saw no flexible flaps?

I get the impression that the flaps are of a gauge similar to Coke can material.

My other question is — How do I know if it’s the reed valves failing or lack of sufficient piston compression for my failure to build pressure?

Response

From your description, it sounds like the valve(s).

Could also (additionally) be the rings.

Did you happen to take pix of it while it was torn down?

Are you saying the diagram is for an HFT machine?

Response

Even if you have severe scoring or other indication, I wouldn’t worry too much about the rings, yet.

It sounds more like your reeds disintegrated.

If you haven’t already, take the heavy thing off and you should find some pieces under it and perhaps in the cylinder. You may have to more or less guess at the original shape, but most are more or less feeler gauge (or finger) shaped. Check out our how to make reed valve for air compressor.

Good luck.

Response

Forgot –

Get that auto oil out of there before you run it much more. Visit our guide on how to change air compressor oil!

Question

I’ve taken it down and checked the reeds… everything is intact.. not getting much on the pressure stroke when I put my palm over the piston. I just need to know where I can get the rings.. thanks.

And, I forgot… it’s blowing a lot of oil by.

Response

If you have a manual, try calling the number therein.

If not, try calling 1-866-797-2738 – it’s been a few years, but if they are still there, may be able to help.

Let us know, please.

Good luck.

(Number is for IMS equipment and/or Sears Parts direct – Moderator)

DeWalt Air Compressor Will Not Build Pressure – DeWalt Air Compressor Troubleshooting

Question

My DeWalt 200psi d55146 will turn on but it won’t build any air pressure and my regulator is stuck, and won’t move.

I think that’s why it won’t build air pressure how do I fix the regulator?

Response

It’s two separate issues, I’m afraid, Damien.

Even if the regulator is totally pooched, the compressor should pump the tank pressure up to the normal cut-out.

That you are not building air in the tank needs to be addressed before the regulator issue, I suspect.

There are many reasons why an air compressor can run but not build pressure. I’ve written about them on pages linked from the Troubleshooting page.

After that issue is resolved, if you still need help with the regulator, please comment.

TA-25100VB Jobsmart Air Compressor Will Not Build Pressure Past 50 PSI – Jobsmart Air Compressor Troubleshooting

Question

TA-25100VB will not build pressure past 50 PSI. The motor changes sound. No leaks.

Response

That happens right around the time the pressure stops rising, right?

Then while there’s no external leak, you probably have an internal one.

If there’s no air coming from the oil fill/breather cap, then the rings are probably OK.

That leaves valves. Check that the head bolts are not loose. If they are OK, then you’ll likely need to remove the head. You’ll find one or more broken “flapper” valves in there. Or, maybe just a bad gasket that gives at 50psi. Either way, replace what’s broken (you’ll need to replace the gasket, at least), and you should have it fixed.

Good luck.

Question

I was able to track my air leak to a broken flapper.

Do you by any chance have a part number for both the gasket and the boomerang-shaped flapper?

Response

You can download the manual from TSC. There’s a parts list, but I don’t know what, if anything, is actually available.

Good luck.

Ingersoll Rand Compressor Won’t Build Pressure – Ingersoll Rand Air Compressor Troubleshooting

Question

My IR will not build pressure and it’s brand new? It’s brand new and will not build any pressure.

They sent me a 23191877 valve & gasket kit but no directions or specs for torque(spelling?)

Looked at the book and there are 2 valves. wtf?

Response

Al, it’s odd, but I guess not unheard of, that a brand new air compressor won’t build pressure.

I know little about your air compressor from your post since you did not identify the model so I can’t do any research on it.

If it’s oil lubed, you would likely have had to add the oil when you got it home.

Compressors are, as you now know well, noisy. It is difficult to hear an air leak from a fitting or tank drain on a running compressor. Take pains, then, to check the tank drain is closed. On some new compressors, they ask you to run the compressor for a period of time with the tank drain open as a compressor break-in process. If yours asked that, did you close the drain?

Pull the air inlet filter and feel if there is suction when the compressor is running. There should be.

If you must tear it down, do so carefully both in terms of reassembly or identifying the location on the compressor of the replacement parts you received.

Know, as again you have found out, that many mass-market, low-cost compressors, have no North American support, and they truly are made to use and then thrown away.

Bambi Air Compressor Not Building Pressure – Bambi Air Compressor Troubleshooting

Question

This Bambi has been working for over 20 years but has stopped building pressure

Any suggestions are appreciated.

Response

It’s still working… but won’t build pressure? Has the sound changed? For sure the tank drain valve is shut after the reservoir was last drained?

Please provide a bit more information as a comment and also visit the compressor troubleshooting page on this site. Follow the links to the pages that talk about why air compressors run but don’t build pressure and do some of the rudimentary checks noted there, please.

What did you find, or did not find? Please provide details and we’ll help to try and narrow the problem down.

Response

It’s obvious, but do you have an air leak somewhere? Air leaks will stop building up.

These hermetic pumps are very low output so air leaks are a NO! NO!

Place your finger on the inlets of the pump and see if any suction is there? No suction then rings/valves are shot so bin it!!

WHENEVER buying an air compressor check the air usage on the tool u r going to operate, rule of thumb is to add one-third to that figure and that’s the size compressor u need.

EXAMPLE:-AIR TOOL using 40lpm YOU NEED A 60lpm AIR COMPRESSOR…any lower and compressor will never cut out, it will wear, it will pass oil into air receiver, it will seize up.

Air Compressor Will Not Build Pressure – Air Compressor Troubleshooting

Question

I have a Yanmar diesel with an Ingersoll rand tank and compressor mounted to a trailer for portability.

The team works fine together until the air gets really hot.

At that point, the engine stays idle and sounds as if it is going to choke down at any second.

I am an aircraft mechanic. I know nothing about air compressors other than how to hook an air tool up to one.

There is an actuator coming from the relief valve mounted on the tank. The actuator is linked to the fuel control on the engine (it sits beside the motor on this trailer).

As I said, it works fine for 10-15 min, then after it heats up good, the pressure barely makes it to 70psi (normally 140-150 easy) and it takes forever to get up to that pressure (at startup, normally 30 seconds and the tank is full)

I have no idea what models these tanks and compressors are at this time.

Any idea as to what is going on wrong?

Any help will be great.

Only bad thing is, that I am in Iraq as a civilian and the availability of hardware stores is slim right now….

Cooper

Response

Howdy Cooper, very nice to have you visiting my site from Iraq.

Trying to diagnose a compressor problem from afar would be tough enough for a compressor mechanic, and it’s even tougher for me since I’m not a mechanic.

So, what’s getting hot? The air in the tank, the compressor itself, the diesel engine?

It sounds like your system is using a pressure bleed from the PRV to modulate the operation of the diesel, in other words, a typical throttle / unload controller.

The actuator presumably shifts one way when the pressure in the tank is low and this opens the throttle on the diesel to generate more air. Then as the pressure of the compressed air in the tank increases, that shifts the actuator again, reducing the speed of the engine. I’m just guessing here.

It sounds like when it gets hot the temperature is negatively affecting the operation of that throttle mechanism, and as you say, “ the engine stays at idle and sounds as if it is going to choke down at any second”.

That would suggest to me that the system is “thinking” that there’s more pressure available than there really is, and it won’t let the motor throttle up.

And if it only happens when it (whatever it is) gets hot, then the heat has to be affecting this throttling mechanism to prevent its proper operation.

That’s about what I can contribute. Sorry I couldn’t be of any help.

Do any other visitors have any ideas for Cooper?

You can certainly use the form to ask a question about what to do when your compressor will not build pressure.

Please provide as much information about your compressor as possible. The make, the model, the age of the compressor, how much it is used, the type of power supply… anything that you can think of that will help us help you with this air compressor problem.

If you’ve got a suggestion about solving the compressor problem that someone else has posted on this page, please add a comment if you would.