When manifolds break they are impossible to fix. When a part on them fails, you often need to buy a whole new manifold, and sometimes finding the right one is difficult.

This page is for folks that have a broken or damaged compressor manifold and want to know how to make your own compressor manifold and where you can purchase parts the required parts.

Table of Contents

- Compressor Manifold

- Make Your Own Compressor Manifold

- Compressed Air Manifold Materials

- How Compressed Air Manifolds are Used

- Mounting the Compressed Air Manifold

- Where to Obtain Compressed Air Manifolds

- FAQs (Frequently Asked Questions)

Compressor Manifold

By compressor manifold I am talking about the part, typically cast, that connects the compressor tank to the discharge coupling on the compressor. In that manifold, the compressor regulator is typically found. Or, another compressor manifold may have many components, including the pressure switch, the PRV, discharge coupler and gauges attached to it.

The thing is, components on the manifold will fail or the manifold itself may fracture. When it does, do you have to replace the whole compressor manifold to replace one part? That is wasteful and possibly unnecessary. The solution is to make your own compressor manifold!

Compressed air manifolds are not complex pieces of compressed air equipment, nor are they hard to understand. Yet compressed air manifolds can be very useful when plumbing your compressed air.

The issue about compressed air manifolds is that if you don’t know about them at all, you may be having some difficulty in plumbing your compressed air that they would provide the solution for.

Make Your Own Compressor Manifold

The idea is to use relatively easy to obtain parts, from plumbing houses to higher quality hardware stores or acquiring the fittings online, to create a manifold that works the same way as the original.

No, when you make your own compressor manifold it will not look the same, and you may even have to permanently remove part of a compressor covering to install the new manifold. That being the case, your choice is a pretty compressor that doesn’t work or one that works and doesn’t look new. Your choice!

It will be necessary to determine the thread and female port sizes of the existing manifold. They may either be metric or NPT. Visit the Compressed Air Fittings page on this site for information about thread sizes if the existing manifold sizes are not known.

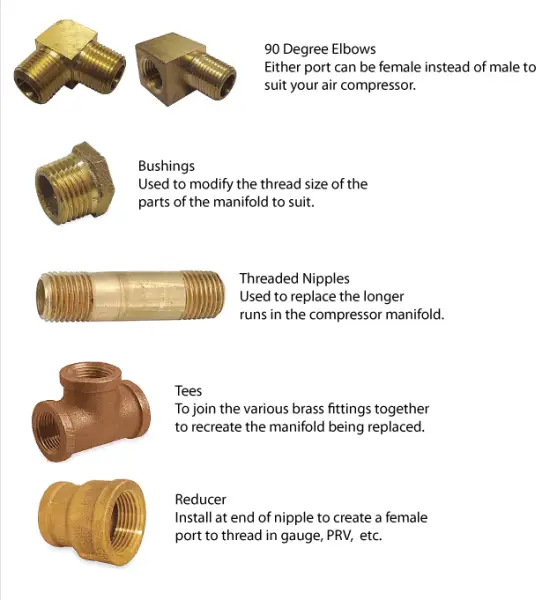

The next step will be to acquire a selection of fairly common brass fittings.

Select an assortment of fittings.

A selection of brass fittings is used to make your own compressor manifold. Images: grainger.com

Use these fittings to emulate the size, shape, and function of the existing compressor manifold.

As long as you recreate the same function of the old manifold, and you can install it on the compressor, you can change the shape and orientation of the ports and locations of ports on the new to suit your own preference. Perhaps you want two discharge couplers, for example? Perhaps the PRV is in the way where it is presently installed? Change a little or change it all. It’s up to you.

Or more frequently, interference between one part or another on the manifold and the compressor makes removing and replacing it difficult.

If that is the case, add a union or two to your new manifold. This will enable faster and easier disassembly of the manifold without having to turn parts that might interfere with the compressor.

Brass fittings are easily obtained online or at good stores, are relatively low cost, and with a bit of thought can be used to make your own compressor manifold, perhaps for a fraction of what a new OEM version would cost.

If the existing manifold cannot be found, making one yourself, regardless of the cost, can get a broken compressor back into use, fast!

I do not know what the compressor manifold on every air compressor looks like. I do know, having done so myself, that you can use standard, off the shelf, brass fittings like those shown to recreate virtually any compressor manifold.

In the future then, when the next component fails and needs to be replaced, doing so is relatively easy. You didn’t simply buy an expensive compressor manifold off the shelf but took the time to build your own with readily, and long-term accessible, available parts.

To ensure that your home-built compressor manifold does not leak, I recommend the use of a paste-type thread sealant like PTFE on all connections.

Compressed Air Manifold Materials

The image is of a basic air manifold and appears to be made of aluminum, excellent material to use since it is rust-resistant.

In the image you can see there is a threaded port on the top, two on the side facing you, and if you look down inside the bottom port, you can see that there is another threaded port on the bottom, as well.

Bring a supply of air to any of these ports, and you now have multiple ports to plumb that supply of air to many locations.

The photo of the compressed air manifold above shows one made of aluminum. In the image below is an anodized manifold.

Manifolds can be manufactured by machining metal or plastics, and are made by the casting process as well. Materials include specialty plastics, aluminum, steel, and white-type casting metals.

Some are manufactured specifically for one application, but most of them are similar in concept to the one above though the shapes vary depending on the number of ports you desire and the manufacturer.

How Compressed Air Manifolds are Used

The user would bring an air supply to the thread on the end, and then install quick connects for fittings in the ports along the side of the compressed air manifold. In this way, one supply would then be able to send air to multiple applications.

This particular manifold is a bit different than the norm. Not only does it have a supply port on either end as most air manifolds do, but this one is blocked midway so that an air supply with one pressure could be plumbed to one end, and a different air supply (or maybe even a vacuum) could be plumbed to the other end. Therefore, each end of the manifold supplies only part of the ports on the side.

Mounting the Compressed Air Manifold

While this will often be dictated by the style and size of the manifold itself, many come with through holes specifically for mounting. The small through-holes can be seen at either end of the manifold.

The Norgren compressed air manifold pictured above is a bit different than others shown on this page. This one contains instant fittings already installed in the airline ports so all a user has to do is mount this manifold and insert polyethylene tubing in the various fittings to supply various parts of a machine with compressed air.

Even what would normally be a supply port on the bottom left end of this manifold has been converted into an instant fitting for the users’ convenience.

Where to Obtain Compressed Air Manifolds

Most of the big box stores that sell air compressors offer a rudimentary selection of manifolds.

If you require a unique compressed air manifold or one made of a specialty material (stainless steel, for example) your best bet is to contact one of the major industrial pneumatic supply companies, of which there are many.

Search in your browser for Norgren, Numatics, or SMC to name just a few, or if you just browse for air manifolds you will find many. Otherwise, you should be able to find your desired parts on Amazon!

Compressed Air Manifold Parts Available On Amazon

Taisher offers 90-degree brass elbows in a variety of male and female NPT sizes!

- 🔧 Feature - 90-degree street elbow for connecting a male-ended and a female-ended pipe at an angle

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Forney provides a 1/4″ female to 3/8″ male NPT brass bushing.

- All brass air hose bushing with female NPT and male NPT ends

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Edge industrial has 1/4″ male, 3″ long brass nipples available suitable for working pressures up to 1200 PSI.

- 1/4 x 1/4, 3 Length, Male NPT Long Nipple

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Merit brass sells a female NPT 1/2″ tee.

- These fittings contain lead and are not allowed by federal law to be installed for potable water use in the U.S.A. and its territories.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Finally, Sungator produces brass reducer adapters that are available in a variety of sizes.

- 【PREMIUM MATERIAL】: Premium solid brass with thicker wall, more durable than iron and iron galvanized pipe fittings, 1/4 NPT male pipe x 3/8 NPT female pipe, 2-Piece

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Other than buying individual parts, you can get sets like this one below that includes nipples, couplings, and elbow fittings.

- 【DURABLE】: Not a cast product, more robust and durable than castings. Max. pressure 120 PSI.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Or this 15 piece set that provides bushings, reducer adapters, and nipples – available in a variety of sizes.

- Reducer Adapter: Premium solid brass with thicker wall, more durable than iron and iron galvanized pipe fittings, 1/4 NPT male pipe x 3/8 NPT female pipe

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Compressed Air Manifolds Available on Amazon

You can buy ready-made compressed air manifolds on Amazon too if you don’t fancy making your own. Tulead offers an efficient and durable metal 4 ways compressed air manifold that is also available in 2 and 3 ways!

- 🔷Package Content:1 x Manifold Block

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

An Amazon choice is this 2-way aluminum pneumatic manifold produced by NACX.

- Air manifold for distributing pneumatic power to multiple locations from a single source.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Another Amazon choice is this Primefit 3-way compressed air manifold that contains brass couplers.

- 3-Way air MANIFOLD and splitter with (3) 1/4-inch brass 6-ball couplers

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

FAQs (Frequently Asked Questions)

Air compressor manifolds connect the compressor tank to the discharge coupling on the compressor. In that manifold, the compressor regulator is typically attached. Some compressor manifolds can have many components attached to them which will include the pressure switch, PRV, discharge coupler, and gauges.

Manifolds are manufactured by machining either metal or plastics, and can also be made using the casting process as well. Materials include specialty plastics, aluminum, steel, and white-type casting metals. Aluminum is a very popular choice due to its excellent corrosion-resistant characteristics.

If you have any questions regarding compressed air manifolds, please leave a comment below, with a photo if applicable, so that someone can help you!