Hey! This site is reader-supported and we earn commissions if you purchase products from retailers after clicking on a link from our site.

With just a couple of minutes running time, or sometimes after ten or fifteen minutes or so, the air compressor reset button always trips on my air compressor.

If this is your compressor problem, this article will provide a few things to look for and perhaps fix if your compressor reset button always trips.

Table of Contents

- What’s the Purpose of an Air Compressor Thermal Overload Reset Switch?

- Where is The Reset Button & What Does it Look Like?

- Why a Compressor Reset Button Always Trips

- How to Stop Your Air Compressor Reset Button From Tripping

- What to Do if You Think Your Air Compressor Thermal Overload Switch Is Faulty?

- Air Compressor Tripping Thermal Reset Button vs Tripping Circuit Breaker

- FAQs (Frequently Asked Questions)

- Existing Reader Reset Button Tripping Problems and Responses

What’s the Purpose of an Air Compressor Thermal Overload Reset Switch?

First of all, let’s discuss the role of a compressor reset button. The compressor thermal overload reset, also commonly referred to as a thermal cut-out, thermal overload, or safety switch, is there to automatically turn off the air compressor’s power when it overheats. Learn about the basics of motor protection here!

The reset button is there to protect the motor from becoming damaged if the compressor begins overheating. That’s also why the air compressor keeps tripping the reset button because the system is becoming too hot. You can typically find the reset button on the end or side of your compressor, and sometimes even located inside the wiring of the motor.

The thermal overload button is used in series with the power supply to the motor and in the event of excessive overload or heating, it cuts off power to the motor to allow it time to cool down.

Some thermal overload switches are manual, and require the big red button on them to be pressed when the air compressor has cooled. Others are auto-reset types, which automatically let the motor restart when it has cooled enough. All thermal reset switches are similar in design, regardless of what electric motor they’re on, whether that’s an air compressor, air conditioner, or heating blower. You can view some thermal reset switches here!

Where is The Reset Button & What Does it Look Like?

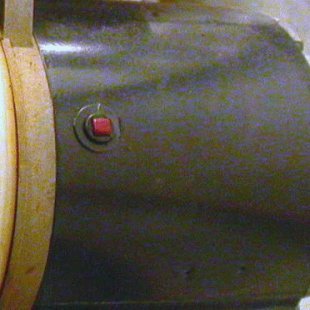

You might know it as the thermal cut-out or thermal safety switch. Others know it as the reset button. You can see one of them on the end of the electric motor in the image below.

It may be a small red button on the shroud of the compressor, it may be a button on the end of the motor if that is visible on your compressor, and I have seen them on the side of the motor at the shaft end, on some compressor motors.

Some are inside of the wiring cover on the motor, others are an inline switch on the wiring. The locations of this important piece of equipment on the air compressor sure do vary.

Regardless of where the compressor thermal reset button is on your compressor – on the motor or on the shroud of the compressor – its purpose is to cut the power to the motor in the event that the motor itself gets too hot.

Without the air compressor thermal overload switch, if there were a condition in the motor that was causing it to get hot, eventually the heat itself would destroy the compressor motor.

If the compressor reset button always trips on your compressor, the motor is getting too hot and you may need a replacement. For information on how to buy a compressor motor reset switch please visit our guide!

Why a Compressor Reset Button Always Trips

There are a few reasons as to why your reset button may be tripping on your air compressor and these are:

- The power supply

- The compressor runs too long

- Centrifugal switch

The Power Supply

Check to make sure that your air compressor is plugged right into the wall socket, and that it is not being powered through an extension cord or power bar. The reason being is that the wire in the extension or power bar may not be large enough to allow the flow of power that the compressor motor needs.

The power cord of the compressor is sized to allow sufficient power to the compressor motor. Restricting it through a smaller wire will cause the motor to overheat. If the motor overheats, the thermal cut-out will shut it down. This is a very common issue.

Compressor Runs Too Long

If you are using your air compressor for extended periods, more than, say, ten or fifteen minutes at a time, the typical DIY air compressor will overheat. The duty cycle of the compressor may be less than the time you are requiring it to run, and the motor will overheat. If you think this is happening to your air compressor, try only running it for ten minutes and then letting it sit for at least that time so the motor can cool, before firing it up again.

Older air compressors – and some not so old if the compressor has tipped over for some reason – can develop a tank check valve leak. If that happens, air will be bleeding out of the tank all the time, even when the compressor is running. If that is happening on your air compressor, it will take much longer for the tank to fill – if it ever does – to cut out, and the by-product of that is a motor that overheats.

See the troubleshooting pages on this site about how to fix a leaking tank check valve.

If your air compressor has or is developing a mechanical issue – perhaps a weakened or broken intake or pressure valve or a blown gasket in the pump, the compressor may have to run much longer than normal to fill the tank to cut out.

It may run so long that the motor will shut down on thermal cutout before the tank is full. If your air compressor seems to be undergoing this scenario, it may be time to add a valve and gasket kit. The troubleshooting pages hyperlinked on this page address these issues.

Centrifugal Switches

Our thanks to Waite Mccormick for providing the following information on centrifugal switches and their role in thermal overload:

Another issue, the centrifugal switch can stick which will keep the start windings energized tripping the thermal switch within 30 sec.

That centrifugal switch is kinda like 1st gear sorta speaking, and when the motor gets almost 3/4 of its design RPM, it shifts the motor windings to the run windings, kinda like a running drive gear.

The start windings are much smaller and can’t withstand the heat (of running full rpm) resulting in the kicking of your thermal overload. Over time, the centrifugal switch can shift out of adjustment, causing it to get stuck in a singular position.

If the centrifugal switch were to get stuck in an open position then the windings won’t shift properly. The start windings can’t withstand the heat of the compressor’s full RPM which subsequently causes the compressor to overheat.

How to Stop Your Air Compressor Reset Button From Tripping

I’ve provided you with the 3 reasons why your air compressor reset button keeps tripping. Now, let’s focus on ways to combat this!

Time needed: 10 minutes

Air Compressor Reset Button Fixes

- Fixing Power Issue

Make sure that the air compressor is plugged directly into a wall outlet that provides 20 amps or more, and do not use power bars or extension cords.

- Fixing Running the Compressor for Too Long

To not overwork the air compressor, or exceed its duty cycle, Run the compressor for say 10 minutes, and then allow it to sit for 10 minutes before running it again. This will allow the engine sufficient time to cool and ensure that it doesn’t overheat and trip the reset button.

- Fixing a Sticking Centrifugal Switch

First of all, you want to make sure the points on the contact plate are in the open position by bending the circular spring flat so the points are no longer in contact. If the points are welded shut, the contact plate needs to be replaced. If there is light pitting on the surface points, you should be able to sand them gently with say 400 grit sandpaper. Anything larger will create an unstable condition and so, the contact plate must be replaced.

Air Compressor Reset Button Tripping Fix YouTube Demonstration

I have picked out the below video as a useful YouTube demonstration on how to fix your air compressor reset button.

What to Do if You Think Your Air Compressor Thermal Overload Switch Is Faulty?

What are your options if it turns out that your thermal overload switch is faulty, and tripping when the compressor isn’t overheating? In this situation, you’re probably better off buying a replacement than trying to DIY fix the switch. I’d first recommend seeking professional advice, whether that is at a repair center or a local compressor store.

Air Compressor Tripping Thermal Reset Button vs Tripping Circuit Breaker

People often confuse tripping the thermal reset button and tripping the circuit breaker. The key difference is that the thermal reset button is solely due to overheating while the circuit breaker is down for a number of reasons. If the motor on the air compressor is unable to start for whatever reason, but still tries to draw power, it may exceed the amperage and capacity of the breaker, causing it to trip.

Circuit breakers are likely to trip due to air filters, broken extension cords, clogged cylinders, faulty pressure switches, failed capacitors, failed unloader valves, and more. For more information visit our Air Compressor Keeps Tripping Circuit Breaker – Why & How To Fix guide!

FAQs (Frequently Asked Questions)

It is likely that your compressor is tripping due to your power supply not being large enough to power the compressor or the compressor is overheating from working for too long and so the reset button trips.

The reset button can be located on the motor or the shroud of the compressor, it typically depends on the make and model of your compressor.

It really does depend on the make and model of the compressor. Some compressors will have their reset buttons wired into the motor, whilst others are located at the end of the compressor.

Reset buttons, otherwise known as thermal switches or thermal reset buttons, are important parts of air compressors as they ensure that air compressors do not overheat to prevent damage to parts and the overall system.

Look for the reset switch, typically a small red or black button near the side of the motor near the power cord, and click this. The location will vary depending on the make and model.

The sole purpose of resetting your air compressor is that it is getting too hot. Therefore it cuts power to the compressor to ensure that it doesn’t overheat any further and subsequently prevent damage from occurring.

Existing Reader Reset Button Tripping Problems and Responses

Harbor Freight Compressor Thermal Switch Keeps Popping Out

Question

I have the 90234 air compressor from Harbor Freight. I have used it quite often for over a year. I have even pushed it on multiple occasions running it nonstop for hours without a break.

Yesterday while using it with my sandblaster the air compressor thermal overload switch popped and the compressor died.

I restarted it to only have it run for about thirty seconds before it died again.

Figuring it needed a rest I left it alone. Today I went to start the compressor only to have it run for another thirty or so seconds and just cut out, it didn’t even fill the tank.

The oil and its level seemed fine.

Is it possible my motor is dying? I have it on a power strip all by itself connected to an outlet without anything else and I never had this problem before even when running the compressor for hours at a time.

I am going to check tomorrow if there is a restriction of some sort on the copper line. If I can get any advice I appreciate it. Thanks

Response

Scott, I don’t know what the Duty Cycle of your model of Harbor Freight compressor is. If you are not sure what I mean by Duty Cycle, see the page of that name linked from the sitemap page for complete info.

I think, reading between the lines, that you know that you have abused the compressor. If, in fact, it is not a continuous-duty compressor, from your own admission, you have run it long and hot, and I suspect, this has damaged your motor, if not the pump.

Sounds like you have had your money out of this one, and since, I suspect, replacing the motor may only solve one of the issues, it may be time to retire this one for parts and get another.

To be sure, find an electric motor rebuild shop, and take the motor there for a load test.

Cheers and good luck.

Here are a number of existing reader problems and helpful responses to reset button problems with various brands of air compressors:

- Central Pneumatic Air Compressor Will Not Stay Running – Central Pneumatic Air Compressor Troubleshooting

- Air Compressor Won’t Start – Ways to Fix Air Compressor Won’t Turn On Problems

- Makita Air Compressor Trips Reset Button

- Kobalt Air Compressor Reset Button – Kobalt Air Compressor Keeps Tripping Reset Button

- Central Pneumatic Air Compressor Keeps Tripping Reset Button

If you have any questions regarding air compressor reset buttons then, leave a comment below, with a photo if applicable, so that someone can help you!