Hey! This site is reader-supported and we earn commissions if you purchase products from retailers after clicking on a link from our site.

What are the head bolt torque specifications for a Craftsman 919.167801 air compressor, say Jack from Warren PA?

Well, Jack, an extensive review of the Craftsman 919.167801 manual shows the warning: “Head Bolts – Check the torques of the head bolts after the first five hours of operation.”

The manual goes on to say as it pertains to “Air compressor Head Bolts – Torquing… The air compressor pump head bolts should be kept properly torqued. Check the torques of the head bolts after the first five hours of operation. Re-tighten if necessary. See Parts manual for torque specifications.”

Unfortunately, we have been unable to find the manual for the parts of this model. I hope someone else has the actual torque specs, Jack. Cause, I sure could not find it.

Torque specs

A visitor with the name pcbeachrat offered the following.

I rebuild/repair/build sandblasters and air compressors and the unit you are wondering about is a craftsman 2 stage air compressor. Their head bolt torque is 25 to 30 psi.30 psi at the most.

When you tighten these head bolts use a criss cross pattern, and to prevent the head from warping or air leaks in between the gasket and head, first torque all bolts, as mentioned in a criss cross pattern but only tighten them all partially first. In other words, torque them all at 15 psi first (in the criss cross pattern) and once all are at 15 psi then re-torque them again another 15 psi which will make the torque wrench still read at 30 psi total.

This method keeps you from tightening one bolt to the total 30 psi and the edge of the head crimping down all the way and then can cause the head to distort/warp on the next bolt if you then tighten it all the way to 30 at one time, do half torque first on all bolts, then the last half in the same pattern as before, criss cross. I also recheck ALL MY HEAD BOLTS about every 5 to 10 hours of use. I went through 4 BRAND NEW PUMPS FROM THE FACTORY once like this, of course the company replaced them for free but I lost alot of money in between shipping times and down time over it, but I found every pump had head bolts improperly torqued (all being way low) before I figured out what was going on with these pumps. I now when I install a pump on a customer’s compressor , automatically check the torque on all applicable bolts on the unit. Anyway…25 to 30 psi on a craftsman 2 stage compressor…..Good luck

A question about torque.

I thought torque values were in inch pounds or foot pounds (for those in the English system). When you refer to 25-30 psi, how is that converted Thanks.

Ft-lbs vs psi

John Sawyer was kind enough to respond with: User “pcbeachrat” does indeed actually mean ft-lbs instead of psi for the head bolt torque.

Info I’ve found online for the head bolt torque for many larger compressor motors is 25-30 ft-lbs, but for smaller motors like the MK246 and similar, the proper head bolt torque is 7-8 ft-lbs (multiply by 12 to get inch-lbs). After I removed my MK246 motor’s head and did some repairs, and then reinstalled the head, I torqued the head bolts to 10 ft-lbs to be on the safe side, and then I checked them again after a few runs of the motor, and found them to be loose again, so I re-torqued them to 10 ft-lbs. As others recommend, the torque on a compressor motor’s head bolts should be checked often to make sure they haven’t loosened up.

Craftsman compressor manuals?

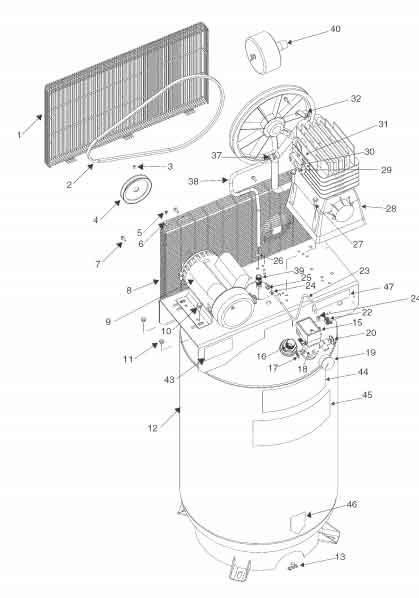

Those looking for the manual for the Craftsman 919.167801 air compressor can find it here, along with the manuals for other Craftsman air compressors.

New comment? New question? Please add it here, along with photos, to help others help you with your compressor and equipment problem!