Rotary vane compressors have been around for a very long time, and are used for many applications other than just compressed air. They tend to be very popular within a wide array of industries due to their energy savings across many levels of air demand.

Not only do they supply necessary compressed air for many applications, but they boast advantages that offer greater efficiency at lower costs.

This page will serve as an overview of rotary vane air compressors, providing you with all the relevant information to help better understand them, including how they work, their applications, advantages and disadvantages, and comparing them with rotary screw compressors.

Table of Contents

- What Is a Rotary Vane Compressor?

- How Does a Rotary Vane Air Compressor Work?

- Rotary Vane Compressor Application

- Rotary Vane Compressors Advantages and Disadvantages

- Rotary Vane vs. Rotary Screw Compressors

- Rotary Vane Compressor Manufacturers & Where to Buy

- FAQs (Frequently Asked Questions)

- Other Types of Air Compressors

What Is a Rotary Vane Compressor?

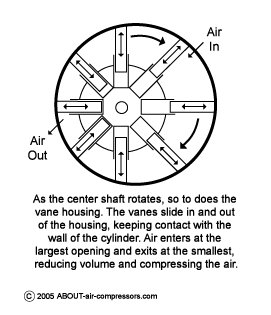

Rotary vane compressors, sometimes referred to as sliding vane compressors, are one of the types of positive displacement compressors and are used in a wide range of industries. These types of vane compressors take advantage of centrifugal forces in order to compress air.

As can be gathered from their name, rotary vane compressors have a cylindrical rotor that is placed off-center in a casing and has a drum in the middle. The air enters and exits the casing through inlet and outlet ports.

There are a number of radial slots in the rotor with spring-loaded vanes fitted to them. The purpose of these springs is to ensure contact between the vanes and the housing constantly. As the rotor rotates, some of the vanes are compressed and some are extended.

An idea of this is presented in the vane compressor diagram below, where we have an inlet and outlet, a single spring-loaded vane that is extended as the rotor moves the drum around the vane compressor.

Note: this is of a vane vacuum and is only a representation of the motion, not an actual vane compressor design.

How Does a Rotary Vane Air Compressor Work?

A vane compressor will have multiple radial slots with spring-loaded vanes fitted in them, and the rotor is placed eccentrically in a way that the drum is closest to the housing at the outlet port and farthest from it at the inlet.

Then, every two adjacent vanes form an enclosed space with the corresponding sections of the drum and housing, so that the air trapped in this space from the inlet port undergoes compression due to the shrinking space (spring-loaded vanes compressing into the drum) as the rotor moves around its axis until it reaches the outlet port.

In order to stop the air from escaping the space between adjacent vanes, there can be some oil lubrication to act as a sealant between the vanes and the housing. But, of course, oil-free designs are available.

An oil-lubricated rotary vane compressor works via the following principles:

Rotary vane compressor working principle

- Air is drawn in

Firstly, the air is drawn into the compressor through the intake valve.

- Air is contained

Air is contained between the rotor and stator wall.

- Air is compressed

Air is then compressed by decreasing the volume (thus increasing pressure). Lubricant is continually injected to cool, seal and lubricate the system.

- Air is passed out

This high-pressurized air then passes into the primary oil separator.

- Lubricant is removed

The remaining traces of lubricant are removed in the final separator element to ensure that the air is of the highest possible quality.

- Air is passed through aftercooler

This system air then passes through the after-cooler, removing most of the condensation.

The lubricant within rotary vane compressors is circulated by the differential air pressure (i.e. no lubricant pump is required). It passes through an air-blast lubricant cooler and filter before being returned to the compressor.

The airflow within the system is regulated by a built-in modulation system.

To learn how to conduct maintenance and troubleshooting tips on a rotary vane air compressor, visit our Rotary Vane Air Compressor Maintenance & Rotary Vane Air Compressor Troubleshooting guides!

Rotary Vane Compressor Application

- Agriculture

- Automotive

- Dry-cleaning

- Energy

- Food and Beverage

- Manufacturing

- Pharmaceutical

Rotary vane technology is used in the list above. As one of the oldest types of air compressors, they have a wide array of applications. With advancements in rotary vane compressor technology, they work very efficiently with fewer pulsations in the flow and, therefore less noise.

Agriculture Industry

Within the agriculture industry, rotary vane compressors serve a vast variety of functions. They supply massive amounts of continuous compressed air for applications such as operating farm equipment, planting produce, or material conveying.

Automotive

Within the automotive and body shop repair industry rotary vane compressors play a pivotal role in supplying compressed air for welding, cutting, tire inflation, air tool operation, and even operating air-operated robots.

Dry-cleaning

As dry cleaning requires the incorporation of chemicals to successfully operate, rotary vane compressors are used to help deliver very accurate amounts of compressed air so that clothing is cleaned with precision.

Energy

Due to the significant variation in jobs within the energy industry, rotary vane compressors are utilized for providing compressed air for drilling rigs in energy exploration and operating turbines. They can also be used for vapor recovery and gas transfer as well as purging and cleaning equipment.

Food and Beverage Industry

Within the food and beverage industry, applications for rotary vane compressors are infinite. Some applications include product handling, the operation of air knives for cutting and peeling produce, vacuums in the packaging process, and even delicate tasks like filling cakes, pastries, etc.

Manufacturing

Rotary vane compressors are a huge part of the entire manufacturing industry, from welding operations to metal and woodworking, they play a large role in today’s advanced manufacturing.

Pharmaceutical

Rotary vane compressors serve to control the equipment used throughout all the processes of pharmaceutical manufacturing.

That’s just to name a few! Let’s not ignore that rotary vane compressors are also used in the medical & dental, natural gas, plastics, and woodworking industries.

Rotary Vane Compressors Advantages and Disadvantages

| Rotary Vane Compressor Advantages | Rotary Vane Compressor Disadvantages |

|---|---|

| Continuous air supply | Difficult and high-cost when multi-staging |

| Easy on-site maintenance | The limited application for high-pressure ratio demands |

| Long life expectancy | Not flexible to capacity control |

| Relatively small and compact | Limited discharge pressure |

| Low initial costs | Some lubricants may enter the air, therefore, additional air/lubricant separation will be necessary |

| Simple design with not so many moving parts | |

| Versatile and efficient | |

| A very small amount of oil is needed for lubrication |

Rotary Vane vs. Rotary Screw Compressors

In recent years, many comparisons have been drawn between rotary vane compressor and rotary screw compressor technologies when focusing on their principles and performance.

While both types of air compressors heavily rely on displacement volumetric concepts, the simple vane principle has been around the longest, up to 100 years old. However, this longevity does not equate to greater energy efficiency or additional capabilities when compared to rotary screw air compressors.

Though a rotary vane compressor has a simpler design and almost double the life expectancy, screw compressors boast more advantages. In regard to turndown rates, speed range limitations, and even energy demand, rotary screw compressor technology advancements and innovations have given them a clear performance advantage in this new era of smart factories.

In high-pressure applications (let’s say above 70 PSI), a screw compressor can usually do the same work as a rotary vane far more efficiently. The initial costs are usually quite similar along with the maintenance costs, so in most cases, you should opt for a rotary screw.

Speed Control

As a rotary vane compressor relies on centrifugal force to operate, they’re at a disadvantage as their maximum speed is limited to approximately a third of that of screw compressors. It is at this maximum speed that rotary vane compressor technology is most likely to wear and subsequently fail.

Rotary vane compressors also struggle at low speeds because the vanes will not fully seal on the stator casings, allowing leakage to occur between the compression spaces and thus, a decrease in inefficiency.

Approximately at speeds of 500 RPM and below, there will be a lack of force for the vane to seal against the stator casing, this will lead to the compressor running unloaded and eventually coming to a halt.

This is certainly where the rotary screw speed control advantages are evident, as they do not suffer such consequences, and instead, can match demand fluctuations without energy penalty.

Rotary Vane Compressor Manufacturers & Where to Buy

- Champion Compressors

- Chicago Pneumatic Air Compressors

- Hydrovane Compressors

- Mattei Compressors

Some of the most reliable, respected, and therefore popular rotary vane compressor manufacturers are those listed above. Though I could not find any of these rotary vane compressors directly on Amazon, Mattei and Hydrovane rotary vane compressors are readily available on Compressor World here.

As well, you could visit the Champion website directly here and browse their catalog of vane compressors.

FAQs (Frequently Asked Questions)

Rotary vane compressors are a type of positive displacement compressor that is used in a wide range of industries. These compressors take advantage of centrifugal forces in order to compress air. They are used for many applications other than just compressed air and tend to be very popular within a wide array of industries due to their energy savings across many levels of air demand.

Rotary screw compressors operate by trapping air between two meshed rotors and reducing the volume of this trapped air as it moves down through the rotors. The reduction in volume ultimately leads to compressed air, which can then be used to power air tools and in numerous other applications.

The vanes inside a rotary vane compressor are the parts eccentrically mounted to the rotor in the stator housing. The vanes are usually manufactured of special cast alloys and during rotation, they are pressed against the stator walls by centrifugal force. This draws air in and compresses it as the volume increases.

As one of the oldest types of air compressors, they have a wide array of applications. With advancements in rotary vane compressor technology, they work very efficiently with fewer pulsations in the flow and therefore less noise. They can be found in the automotive, agriculture, energy, pharmaceutical, and food and beverage industries, to name a few.

Other Types of Air Compressors

If you’re interested in finding out more information on other types of air compressors please visit our specific pages:

- Rotary Screw Compressors Explained

- Reciprocating Air Compressors Explained

- Centrifugal Compressors Explained

- Axial Flow Compressors Explained

- Scroll Air Compressors Explained

- Oilless Air Compressors vs. Oil Compressors

If you have any questions regarding rotary vane compressors, please leave a comment below with any photos if applicable so that someone may help you!