How long does it take for an air compressor to fill an air tank?

I have been asked that question many times on this website, and since there appears to be a good deal of interest, I have added a page to this site dealing with how long it takes to fill an air tank.

How long to fill an air tank?

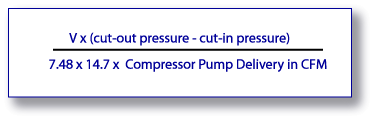

You need to gather some information about your air compressor first, and then plug the information into the formula shown.

- V = Tank size

- Final pressure (cut-out pressure)

- Initial pressure (cut-in pressure)

- 7.48 – conversion from gallons to CFM

- Atmospheric pressure = 14.7

- Compressor Pump Delivery in CFM

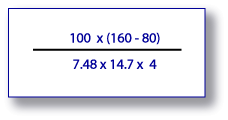

Example:

- My tank size = 100 gallons

- Cut-out pressure = 160 PSI

- Cut-in pressure = 80 PSI

- Conversion = 7.48

- Atmospheric pressure = 14.7

- Compressor Pump capacity = 4 CFM

That gives us:

Therefore:

100 x 80 = 8,000

Divided by:

440 (7.48 x 14.7 x 4 rounded up)

= 18.2 minutes

Folks, you are welcome to use these calculations yet be a bit cautious. While the information is sourced from a number of reputable locations I cannot be 100% sure of the accuracy, and therefore, you use this information at your own risk.

If you need to be 100% sure, get an air engineer to help you.

If you have a question about how long it takes to Fill An Air Tank, feel free to post it here.

Maybe an engineering type will see this page and offer some help!

Please add your question here, along with photos of the compressor and tank in question.