An Air Muscle compressed air actuator; what the heck?

This device, also known as a pneumatic muscle or air muscle, is technology that not a lot of folks know. Yet, this unusual compressed air actuator has been around for years now.

When you want to move your arm, your brain sends a signal to a muscle that, upon receipt of that signal, retracts. That retraction pulls the arm in the direction required. To move the arm to other way, the brain signals another muscle to retract, and the arm moves that way. In both cases, the opposing muscles have been ordered to relax.

An air muscle actuator works in a similar fashion.

If you have some tooling that is required to be moved a relatively small, but consistent distance, an air muscle might be your actuator of choice.

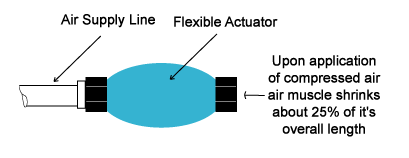

The graphic above represents a “typical” air muscle. On one end is a fitting port (some come with press in instant-type fittings rather than a threaded fitting) and on the other end of the air muscle is a tooling mounting point. This could be a FNPT thread or similar mount.

When air is introduced to the air muscle, it contracts, as show in the drawing below.

When air is introduced the air muscle contracts, and pulls the tooling the same distance very time.

Air Muscles are single acting type actuators, meaning that they will require either an internal or external force to reset them, or revert them to their resting state. Air entering the air muscle contracts them, and it is a mechanical force that is necessary to extend them. That force may be a spring on the tooling, might be gravity pulling the tooling, something is exerted on the air muscle when air is exhausted from it to allow it to extend back to its normal resting state.

They are also a considered a rod-less air actuator as well.

Pneumatic air muscles can be used horizontally or vertically. Some are used to hang tooling, using themselves as the tooling attachment to the machine.

There are, of course, limitations on the amount you can extend an air muscle, else it will get a sprain!

By the same token, an air muscle has limitations on its contraction force, this determined by its bore size.

Unlike other linear actuators, the air muscle has its greatest force when it begins pulling. The contraction of the air muscle with the introduction of compressed air reduces the amount of surface area upon which the compressed air can work, thus self-limiting it’s force. That makes the air muscle ideal for shock absorption, for example.

As I mentioned, various companies offer a variety of bore lengths of this type of actuator. Others offer the air muscle in fixed lengths with connectors already attached. Others (Festo is one) offers some of their air muscles in a tube form, that you cut to length and add the connectors you wish.

Given a non-changing load weight, the amount of air pressure you flow into it an air muscle will change its contraction distance. For example, 50 PSI into an air muscle provides, say, 1/2″ of travel, 100 PSI into the same air muscle results in 1″ of travel. The same air pressure would generate the same amount of stroke, every single time in the same air muscle.

Want to move something very slowly? Supply air to the air muscle with an electric regulator that slowly increases pressure, and the air muscle will creep as it slowly contracts.

When considering using an air muscle you have to think about the application to determine if this technology will suit. Here are some things to consider:

- What’s the load weight and size?

- Direction of travel – is horizontal or vertical?

- What is the desired stroke length?

- What’s the cycle rate?

- What type of airline connection and size?

- How will you control the air pressure?

- How will you connect the air muscle to the tooling?

- Does the load require a guide mechanism?

Some vendors will provide software into which you can load the specs of your application and the software will select the right unit for you. Most vendors will provide CAD support drawings that you can use to drop the schematic of an air muscle right into your circuit diagrams, eliminating the need for drawing them each time.