My air compressor has a copper line on it and after it had been running for a long period of time the copper line was very hot – melted my rubber air hose. Why does my compressor line get hot?

Interesting question, Mr. Griffeth.

I am working on the assumption, since you do not say so, that the copper line you refer to is the one running between the compressor pump head and into the compressor receiver?

And the rubber hose that was melted by the hot copper tube, that was your feed hose to your tools, and somehow it was laying on the copper tube?

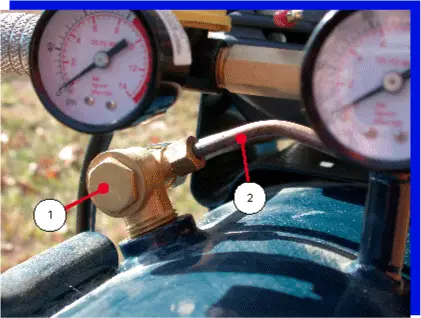

If my surmises are correct, then the copper tube is the one that is plumbing compressed air from the compressor pump down into the tank through a check valve. You can see that as item #2 in the image. Item #1 is the fitting that has the tank check valve.

There are three sources of heat that affect that tube…(four if you use the compressor when the temperature outside is really, really hot!).

The process of compressing air in the head generates heat in the compressed air itself. Each time the compressor piston cycles it is pulling in free air molecules from outside of the intake filter, then cramming (note the very technical term!) those same free air molecules together, driving out the pressure valve, into that copper tube, and in the process, forcing them to rub up against each other.

We all know that friction creates heat. Just briskly rub your hands together quickly for a few seconds and feel the heat buildup on the palms of your hands. That same friction, between the millions of air molecules inside the compressor, makes the compressed air really hot. That heat transfers to the tube as the air is forced down, past the check valve, into the receiver. The longer it takes your compressor to reach cutout pressure and stop, the more heat that is generated by the flowing compressed air.

The next source of heat is the electric motor. The electric motor will get almost too hot to touch after it has been running for a while. That heat transfers through all metal components on the compressor, including the copper tube.

Last source is the heat from the friction within the moving parts of the compressor head itself. The compressor pump head gets very hot and you will burn yourself if you touch the compressor head after it has been running a while. That heat, too, transfers to the copper tube.

As long as your use of your air compressor does not exceed that air compressor Duty Cycle, the heat buildup is normal, and will not negatively affect the use of the air compressor, unless, of course, you lay a rubber air line up against the hot copper tube. Then, all bets are off.