Compressed air couplers are part of the compressed air line connection tag team, the couplers, and connectors. There is a page about compressed air connectors on this site too if you wish more information on them.

This article will provide you with all the relevant information on pneumatic couplings, their relationship with connectors, and a buying guide!

Table of Contents

- What is a Pneumatic Coupling?

- Pneumatic Coupling Buying Guide

- Pneumatic Couplings and Connectors

- FAQs (Frequently Asked Questions)

What is a Pneumatic Coupling?

If you have threaded an airline connector into the supply port of each of your air tools, which is what you want to do to be able to connect a compressed air supply to each quickly and as needed, those connectors allow the quick connection of any air tool (or any other air component, for that matter) to a mating coupler on an air hose.

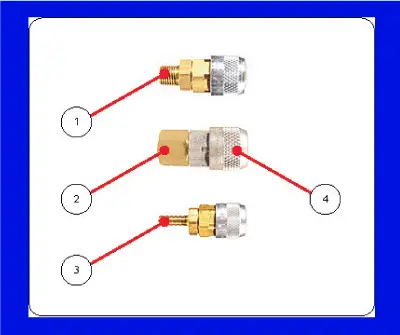

In the photo below all of the couplers are from the same manufacturer though each has a different method of being connected to an air hose or air appliance.

Item 1 shows an NPT thread, item 2 is a female NPT thread and item 3 is a barbed fitting. Item 4 shown on each of these air couplers is very important! Item 4 in the photo above is the critical concern when acquiring couplers.

Pneumatic couplings are known by a whole variety of names:

- air hose coupling

- air hose quick connect coupler

- air coupling

- pneumatic coupling

- pneumatic quick coupler

- compressed air coupling

- compressed air coupler

You get the gist! When buying couplers you need to make sure that the internal configuration of the new coupler (the inside of item 4 shown in the image) matches the external shape of the mating connector.

In order for the coupler to connect properly to the connector, it must be a compatible design. If not, you may not be able to insert your connector into the coupler at all, or if you can, it is possible that the two will blow off unexpectedly.

Though there are some industry standards for couplers and connectors it is an unfortunate truth for compressed air users that sometimes a coupler from one company won’t fit the connector from another company, and the reverse is true as well.

Pneumatic Coupling Buying Guide

When you select new couplers for your home workshop, it is convenient and easy to buy kits with matching couplers and connectors. As they are so many pneumatic coupler types and air hose coupler types, it’s important to ensure you walk away with the right high-quality pneumatic coupler!

What I normally do is select one brand from my local outlet, buy lots of couplers and mating connectors, and then discard all of the others that do not connect, or are suspect. Do yourself a favor and only keep compatible brands of couplers and connectors in your tool crib or toolbox.

For the industrial user, you can purchase quality couplers and connectors from your industrial compressor distributor or industrial supply house. The same rule applies. Only keep compatible brands in stock. Otherwise, you’ll always grab the wrong one when working on a new application, necessitating a trip back to the tool crib and wasted time.

Leak Issues With Compressed Air Couplers

As a home workshop coupler user, expect that the low cost, big-box store couplers and connectors are sometimes hard to connect, may too easily disconnect, and they leak, particularly if you “sideload” the coupler/connector at all.

It’s very easy to do. If you are using an air drill or grinder or air nailer or any air tool that has its connector plugged into a coupler on the air hose, it is almost impossible not to impart a sideways motion to the coupler-connector connection as you are using the tool. In so doing, you are side-loading that connection.

When that occurs, the coupler/connector can leak, particularly if it is a low-cost set. You will hear the connection hissing, and in so doing, bleeding compressed air, the energy that was used to compress the air, and the money you spent on that energy, to the atmosphere!

If you buy a high-quality pneumatic quick coupler and connectors, they are more reliable, easier to insert and remove, and are generally able to better resist leaking, important issues if you are using compressed air regularly and often.

Some couplers even offer additional functions such as an integral relief valve to vent trapped compressed air safely before disconnecting the coupler from the connector, a considerable improvement over popping the two apart when there is air trapped in the line.

For most DIY users, however (including myself), the low cost of our couplers and connectors offset the annoyance of periodic leaks and connection foibles, though I sure do curse the darn things from time to time.

To learn more about leaks, visit our Compressed Air Leaks – How to Find And Fix Leaks In compressed Air System guide!

Best Pneumatic Coupler

To be able to pick out the best pneumatic coupler, or best pneumatic quick coupler, or best air hose coupler, pay close attention to the material of the air coupling as it affects price, durability, and chemical resistance. The most common pneumatic air coupling materials include:

- Galvanized steel: Tend to be the cheapest steel material choice but are suitable for dry applications.

- Hardened steel: More durable than galvanized steel but is comes at a slightly greater cost.

- Stainless steel: Very good chemical resistance and durability but comes with another increase in price.

- Plastic: Depending on the quality of the plastic, they can be durable enough for most applications and come at a far cheaper price than the steel alternatives.

The material and quality of the nipple are also very important and should be checked regularly when replacing leaking couplings. These are often forgotten because they don’t leak themselves.

However, a damaged nipple will cause the seal in the quick-release coupling to become defective or damaged, resulting in a leakage of compressed air. Ultimately, it is more cost-efficient not to save on high-quality insert nipples.

Here’s an example of a pneumatic coupler kit readily available on Amazon. You’ll be able to find anything you need on Amazon, whether that’s a 3/8 air hose coupler, pneumatic coupler air connectors, or a pneumatic cylinder and coupler.

- 【DURABLE MATERIALS】: Material of solid brass is of corrosion resistance and offers a longer life

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Pneumatic Couplings and Connectors

There is often a lot of grunting and hissing occurring when one tries to insert a connector into a coupler.

The grunting is from the person who is trying to hold the coupler, slide the knurled ring back towards the hose with the same hand, and at the same time trying to insert the connector into the coupler with the other hand.

Escaping compressed air provides the hissing, while we grunt, trying to get the darned things to connect. It seems that we never have enough hands.

In the photo above, item 1 is the coupler. One way to connect the two is to simply push the connector into the coupler. A good quality coupler may simply snap back and into place, holding the connector tightly.

Of though it is necessary to hold the coupler and hose in one hand, and pull back on the sleeve (the knurled part) of the coupler with the fingers of that same hand.

At the same time, you push the connector, item 2, into the coupler with the other hand until it bottoms out.

When the connector is inserted/seated all the way, you release the knurled ring on the coupler (not the coupler itself, just the ring) which is spring-loaded, and it snaps forward. You then, carefully, ease off on holding the connector just a bit, until you are sure that it has been captured by the coupler.

Don’t let go of either component completely until you are sure they are mated. Sometimes they pop apart, with a lot of hissing. Been there and done that!

If you’re wondering how to add a second coupling, visit our article here!

FAQs (Frequently Asked Questions)

A pneumatic coupling is a component used to connect compressed air tools to a compressed airline. These pneumatic couplers allow a tool to be easily connected and disconnected to and from a hose or pipe while it is under pressure. As soon as it is disconnected from a component the coupling closes the line automatically, ensuring the system stays pressurized.

There are two main types of air compressor couplings, and these are automotive and industrial. The stand-out difference is that Industrial style couplers have two stripes going across the fitting, whereas the automotive-style only has one. Visit our Industrial vs Automotive Air Fittings guide for more information!

Pneumatic hoses, also known as air hoses or air compressor hoses, are designed to carry compressed air to pneumatic tools, nozzles, and equipment. Some types of air hoses may also be used to convey other substances, such as water and mild chemicals. To learn more about them, visit our hose guide here!

If you have any questions regarding pneumatic couplings, please leave a comment below, with a photo if applicable, so that someone can help you!