Compressed air pneumatic systems require methods of safe and precise control of force, velocity, and direction of movement. Pneumatic valves are important in compressed air systems as they provide this, they’re responsible for controlling, pressure, rate, and amount of air that can move through the system.

This article will provide you with all the relevant information on pneumatic valves and the different types!

Table of Contents

- Types of Compressed Air Valves

- Valve Actuators

- Compressed Air Valve Specifications

- FAQs (Frequently Asked Questions)

- Further Reading

Types of Compressed Air Valves

Compressed air valves, sometimes also referred to as directional control valves, can be categorized in a number of different ways. These include:

- The mechanism that is used to open or close the ports

- The number of entry and exit ports

- The number of flow paths or switching positions that are available

- The position the valve it is when in the un-actuated state

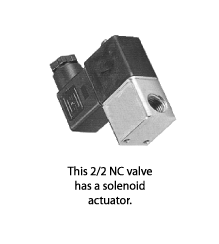

Normally Closed (NC) means that when the valve is not being actuated, compressed air will not pass through it. If the solenoid in the valve shown above is not getting an electrical signal, then the valve is in its resting state. It is not being actuated.

On the contrary, Normally Open (NO) means that when the valve is not being actuated, air will pass through it. It is “normally open”. There are some circumstances where an air circuit designer might want air to be flowing through a specific valve when the circuit is turned off, and in those circumstances, might specify a 2-2 N.O. air valve.

Valves that control the direction of airflow or prevent flow altogether, are functional directional control valves. These devices can be used to connect or disconnect the main compressed air supply from the system, as well as many other uses.

With all of this in mind, we can categorize compressed air valves into the following types:

- Two-Way Compressed Air Valves

- Three-Way Compressed Air Valves

- Four-Way Compressed Air Valves

- Five-Way Compressed Air Valves

- Spring Offset Compressed Air Valves

Let’s take a look at each in more detail!

Two-Way (2/2) Compressed Air Valves

A fairly simple air valve might be designated as a 2/2 air valve, or perhaps a 2/2 air valve. That designation might be followed by the letters N-O. Though two-way pneumatic valves can be either open or closed.

This compressed-air valve has two working ports – one for air supply in, and another for air supply out to the application. An air piloted 2/2 valve might also have a third airport for the pilot signal to enter and shift the air valve.

It can only be shifted into one of two positions – either it is opened, compressed air flows through it, or it is closed, no air flows through it. It is a normally open (NO) or normally closed (NC) air valve in its resting state.

The first ‘2’ in an air valve is designated as a 2/2, which refers to the number of ports that the valve has. The second ‘2’ refers to the number of positions that valve will have.

In the picture above, the second of the two airports is hidden. It is directly opposite the port shown. You normally cannot tell by just looking at an air valve whether it is an NC or NO configured valve.

Three-Way (3/2) Compressed Air Valves

The next valve I will talk about is the 3/2 air valve. As noted earlier, the first number in the valve designation is the number of working ports that the valve has, and the second number indicates the number of positions that the valve has.

A 3/2 air valve will have an in port, an outport (to the application), and an exhaust port, a total of three ports. The second number in the 3/2 valve designation is a two, so this valve will have two positions it can be shifted into.

At rest, the 3/2 air valve will either be open, with compressed air flowing through it and out the power or working port to the application, or it will be closed. When it is closed, compressed air will be stopped by the valve supply or in port, and the working port that let the airflow to the application when this valve was open, will now allow that same air to flow through the air valve to the exhaust port and out to atmosphere.

The first port on a three-way pneumatic valve is used to connect to an actuator, the second is connected to the airflow, and the third is used as an exhaust. Three-way valves are typically connected to actuators or used in pairs for connection with double-acting cylinders.

Four-Way (4/2) Compressed Air Valves

Next in the series is the 4/2 air valve. More complex air valves are required for more complex air-using appliances, and the 4-2 air valve is one of these.

The 4/2 valve will have four working ports, and it will have two positions into which it can be shifted when actuated.

The four ports work so that one port acts as a supply port, which brings compressed air from the compressor to the air valve. Two ports can be plumbed from the valve to two separate applications, or together to one air cylinder, and one exhaust port which will allow air to travel back through the valve to atmosphere, alternately from one of the working (application) ports.

These are amongst the most common types of pneumatic valves found in compressed air systems because the four distinct ports allow the valve to effectively reverse the motion of a motor or air cylinder.

Five-Way (5/2) Compressed Air Valves

The 5/2 compressed air valve functions similarly to the 4/2. The additional port is added often to provide dual pressure, allowing the valve to apply one of two kinds of pressure and alternate between them, depending on what the application requires.

The 5/2 air valve will have one compressed air supply port, two working or application ports to supply air to the application, and two exhaust ports through which air will flow to atmosphere alternately from each of the application ports. It’s also possible, however, that the valve to use the additional port as a second exhaust port.

Five-Way (5/3) Air Valves

The 5/3 is an even more complex air valve. The 5/3 valve will have five ports, 2 exhaust ports, 2 working or power ports, and 1 air supply port. Just as the 5/2 valve does! Rather than the two positions that most valves have, however, the 5/3 valve will have three operating positions. These are the pressure center, exhaust center, and blocked center.

For more information on 5/3 compressed air valves, visit our drawing guide!

Spring Offset Compressed Air Valves

This type of compressed air valve refers to the manner in which the air-flow direction is switched. Let’s take the two-way directional valve as described earlier as our example here. For each port on the valve to be in an open or closed position, an actuator must move a valve spool to its position. A spring then releases the spool to return the compressed air valve to its previous position. Any two-way compressed air valve that functions in this way can also be referred to as a spring offset pneumatic valve.

Valve Actuators

Regardless of the type of air valve your application needs, every single valve will have some sort of a valve actuator, or in some cases, valve actuators.

If you have experience with compressed air valves, you will be comfortable with the term manual actuator. This simply means that the valve is actuated by an operator (person) that pushes a button, moves a lever, toggles a switch, to make the air valve shift.

For complex air circuits that demand multiple and sequential operations of devices, the valve of choice will typically be solenoid operated.

Valve Operator Versus Actuator

Please note that I define an operator as a person that actuates a valve, and an actuator (sometimes noted as an external actuator) as the device on the valve that actually shifts it.

This is my personal definition, and you may find that other people have different terms for the same thing. Make sure when you are talking to folks about valves that you understand their terms, will you?

Compressed Air Valve Specifications

Compressed air valves have specifications that are general guidelines for what to look for when purchasing a compressed air valve. Though, it is important to understand that individual valve manufacturers will characterize their pneumatic valves differently.

Some specifications to look out for:

- Coil rate voltage (for electrically actuated valves) – this is the measure of the maximum voltage that can be sustained by the actuation coil, typically rated in DC and AC volts

- Cycle rate – this is the maximum number of valve cycles that the valve is capable of operating at per unit of time

- Flow capacity – this is the measure of the valves capacity to move or allow air to flow through it. The flow coefficient (Cv) represents the proportionally constant between differential pressure and flow rate

- Operating medium – this is the type of media that a valve can control safely (compressed air)

- Operating pressure – this is the amount of pressure that the valve is able to handle (typically a range of pressure)

- Port size – this is the physical parameters that define the thread style and the port sizes on the valve (dimensional)

- Response time – this is the amount of time required for the valve to switch positions once it is actuated

These specifications, however, can depend on the manifold design, the actuation mechanism, and the desired porting amongst other factors.

FAQs (Frequently Asked Questions)

The most common types of pneumatic valves are two-way, three-way, four-way, and five-way directional valves, and offset valves. The number depicts how many ports the valve has, for example, a three-way directional valve has three ports, in this case, each serving different purposes.

Typically most pneumatic valves work in a similar manner. Their concept involves pressurized air being fed into an area inside the valve where in turn a valve stem is forced to move and either open or close the valve.

Pneumatic valves are most commonly used for directional control or divert the flow of compressed air in a system. The valves are used to drive other components like actuators or even pilot other valves.

Further Reading

There are a number of specialty valves available for specific applications such as emergency stop valves, soft start valves, check valves, blocker valves, and so on. There are some pages available on this site that may be of interest to you, please visit them below!

For the novice, for the newcomer to the world of pneumatic fluid power, many of the terms used and products discussed will be confusing. I will clarify as much as possible, and continue to provide a huge amount of information on this site about those terms and products.

Additional valve reading:

- Pneumatic Flow Control Valves – What Are They, How Do They Work?

- Air Compressor Air Line Non-Return valves/Inline (In The Air Line) Air Check Valves Explained

- Check Valve Sizes

- What is Check Valve Cracking Pressure

- Air Compressor Troubleshooting Check Valve

- Air Compressor Unloader Valve Explained

- Unloader Valves On Twin V Piston Compressor Guide

- 5 3 Valves Explained

- 5-2 Air Valves

- 4-2 Compressed Air Valves

- 3-2 Air Valves

- Drawing a 5/3 compressed air valve

- Draw A 5/2 Air Valve

- Pneumatic Soft Start Valves

- Solenoid Pilot Air Valves

- Compressed Air Solenoid Valve Guide

- Air Compressor Auto Drain Valves Guide

- Needle Valve vs Ball Valve

- Globe Valve vs Ball Valve

- Globe Valve vs Gate Valve

- Butterfly Valve vs Gate Valve

If you have any questions regarding compressed air valves, please leave a comment below, with a photo if applicable, so that someone can help you!