There are many types of valve actuators, with solenoid pilot actuators being one of them. This page provides information about what they are, how they work, and how to apply this information to a valve selection.

A solenoid pilot valve actuator is a device that is used to operate larger compressed air valves.

There are pages on this site about direct acting solenoid valve actuators. In those pages I discussed how it is impractical to use a direct acting solenoid to actuate larger compressed air valves, due to the relative low valve shifting force of a direct acting coil. With a small distance (10th of an inch or so) a direct acting coil generates sufficient force. Longer than that, there may not be enough shifting force to work the air valve reliably.

If longer distances are required to shift the valve poppet or spool, as they are in the operation of all larger air valves, the direct acting coil cannot be used as it does not have enough power to shift the valve mechanism what is a long distance in terms of valve operation.

Table of Contents

- Use Electricity To Operate Big Valves?

- A Solenoid Pilot Uses Compressed Air To Shift The Valve!

- A Solenoid Pilot acts like a Miniature Air Cylinder

- Solenoid Pilot Operation

- Benefits Of Solenoid Piloted Air Valves

- Issues With Solenoid Pilot Valves

Use Electricity To Operate Big Valves?

If a direct acting solenoid cannot be used to shift the poppet or spool in a larger air valve, how do we use an electrical solenoid coil to shift the internal mechanism of larger compressed air valves, then?

That is where the solenoid pilot valve actuator comes in.

For small valves with low shifting distances the direct acting solenoid valve actuator does work well. With reasonable quality compressed air flowing through it, direct acting solenoids (and the small valves they actuate) can be relied on for millions of cycles with little or no problem. They are the right product for the right job.

What is it that the small, direct acting solenoid air valve controls? Compressed air, of course. And why do we use compressed air to do work? Because, compressed air is able to exert a significantly greater force than many other energy sources.

What is it that we need to shift the internal workings of larger air valves? Higher force. In fact, the valve mechanism requires enough force to ensure that the valve poppet or spool will shift reliably against friction, sometimes air borne debris, changing conditions with the valve, yet the valve is expected to work when required to.

Why not harness compressed air to move the spool in larger air valves?

A Solenoid Pilot Uses Compressed Air To Shift The Valve!

Then, why not use a small, relatively (for its size) powerful and reliable small direct acting solenoid valve to solenoid pilot-operate a larger valve? And of course, industry does.

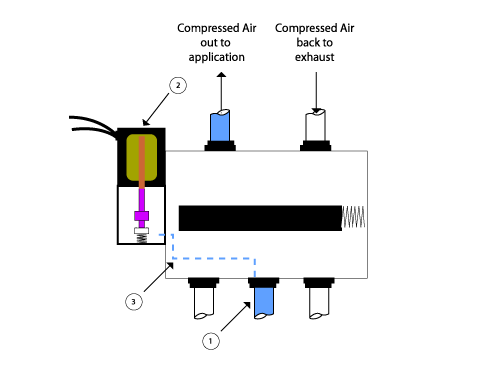

In the drawing I show a small, direct acting solenoid valve, installed on the end of a much larger spool valve, item #2.

Item #3 shows the supply line of compressed air to that small, direct acting solenoid valve. The supply of air to the small valve is taken internally from the main valves compressed air supply (item #2).

In the drawing, the small direct acting valve is drawn as de-energized. As a result, the main, larger valve is in it’s resting position. The spool is to the left, and the internal main valve actuator, the spring, is extended.

For simplicity, I chose not to try to show the flow paths in the main valve, or those in the small direct acting valve.

Inside the larger air valve will be a spool or a poppet. The end of that spool or poppet will be as big as the valve body will allow.

When we are talking about power; Force = Pressure x Area. With compressed air force measured in PSI.

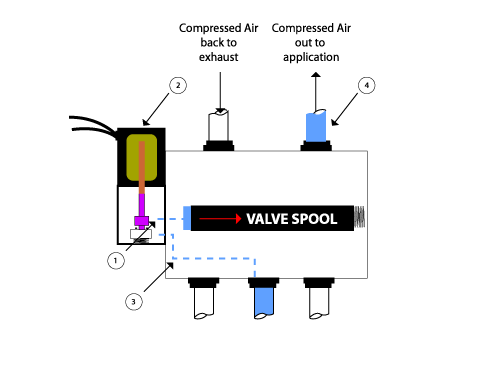

In this drawing, item #2, the direct acting solenoid pilot valve, has now been energized.

The pilot air (item #3) which had been flowing to the direct acting solenoid pilot valve is now flowing through it (item #1) and filling the area in front of the valve spool.

This pilot air is pushing on the end of the spool similar what happens to a piston in an air cylinder. Since the air is trapped there, it builds pressure and exerts force on the end of the spool. When that force becomes great enough, the spool will be shifted over against the internal spring, and the flow paths through the main valve will change. This all happens in a fraction of a second.

Item #4 shows that in this drawing the air is now flowing out the other cylinder port to the application, and the other port is now flowing to exhaust.

A Solenoid Pilot acts like a Miniature Air Cylinder

What we have here is essentially a miniature air cylinder inside the main valve body.

If the end of the poppet or spool inside the larger valve body has a surface area of 1/2 a square inch for example, and the air pressure flowing through the lines is 100 PSI, the compressed air pilot signal will be able to generate 50 lbs. of pushing force on the end of that poppet or spool. This is a huge force available to shift a valve poppet or spool.

Solenoid Pilot Operation

The solenoid air piloted valve will typically operate as follows.

- the solenoid gets an electrical signal

- electricity will magnetize the coil inside the solenoid

- the magnetized coil will cause a pole piece (attached to the internal air control mechanism of the small valve) to shift

- air will flow through the internal air paths of the small direct acting solenoid valve

- and compressed air flow into and will be used to shift the bigger valve spool

- when the air is exhausted, typically an internal spring will shift the poppet or spool back

Very neat, and very effective!

Benefits Of Solenoid Piloted Air Valves

A small amount of compressed air bled off the main supply line of the large power valve can shift massive valves using solenoids with low electrical demand (and low wattage) and use very small sized coils.

The larger the spool inside the main valve, the larger the spool or poppet end-surface area can be, and the greater the shifting force in that valve when air flows into the spool/poppet area from the solenoid pilot valve.

The greater the shifting force available from the solenoid pilot, the larger the spool or poppet return spring can be, giving designers the ability to select higher-flowing air valves, with the expectation of a high level of reliability of air valve operation.

Issues With Solenoid Pilot Valves

The solenoid pilot operated air valve will typically have a minimum operating pressure. How does a solenoid pilot operated valve control vacuum then, since there is no air supply.

To use a solenoid pilot actuator on a valve to control vacuum, an air supply must be plumbed to the solenoid actuator.

Typically, solenoid air piloted valves have a small port on the direct acting solenoid valve so that higher compressed air pressure can be brought to the valve, to provide the shifting force, while the larger valve is controlling the flow of low pressure compressed air or vacuum.

Additional valve reading:

- Types of Compressed Air Valves – Guide To Pneumatic Valves

- Pneumatic Flow Control Valves – What Are They, How Do They Work?

- Air Compressor Air Line Non-Return valves/Inline (In The Air Line) Air Check Valves Explained

- Check Valve Sizes

- What is Check Valve Cracking Pressure

- Air Compressor Troubleshooting Check Valve

- Air Compressor Unloader Valve Explained

- Unloader Valves On Twin V Piston Compressor Guide

- 5 3 Valves Explained

- 5-2 Air Valves

- 4-2 Compressed Air Valves

- 3-2 Air Valves

- Drawing a 5/3 compressed air valve

- Draw A 5/2 Air Valve

- Pneumatic Soft Start Valves

- Solenoid Pilot Air Valves

- Compressed Air Solenoid Valve Guide

- Air Compressor Auto Drain Valves Guide

- Needle Valve vs Ball Valve

- Globe Valve vs Ball Valve

- Globe Valve vs Gate Valve

- Butterfly Valve vs Gate Valve

If you have any questions regarding Solenoid Pilot Air Valves, please leave a comment below, with a photo if applicable, so that someone can help you!