by Jason

(Grand Blanc Mi)

It should start at 90psi and shut down at 125psi. It just continues to run and I do not know why??

When I mess with the switch from off to auto it did briefly stop yesterday but after another switch up and down it again started to run and will not stop??

Does anyone know what could be causing this? How can it be fixed? Also my compressor is a Coleman Black Max 27 gallon 5hp oiless compressor vertical style.

Does anyone know where the air filter is located?? Shouldn’t it be cleaned/checked or changed from time to time?? Any answers would be great. Thanks

Hello Jason…

What happens when your compressor doesn’t stop? Does the pressure relief valve pop open? Or, does the pressure in the tank get to a certain level, and then rises no higher, so the pressure switch never “sees” the normal cut out pressure.

The answer to those questions can point to the issue with the compressor switch.

It does sound like your pressure switch is pooched, though.

The pressure switch senses the pressure inside the tank and when that pressure reaches the set point, it both shuts off electrical power to the motor, and unloads the air compressor.

If this isn’t happening, then you may “enjoy” a catastrophic failure of your air tank, meaning that if the PRV doesn’t function as it’s supposed to, your compressor tank can get over-pressurized. My advice, get it fixed, fast!

As to the air filter, your compressor will have an air intake port up around the top of the compressor head. Usually it’s got a black plastic doo-dad screwed into it and there will be a hole in the bottom of this into which free air flows as the compressor works. That air passes through an intake filter inside the plastic housing before it gets to your cylinder.

That unit can be unscrewed from the compressor head, the cover should pop off, and the filter inside can be examined and, if necessary, cleaned.

Bill

Replacing the air pressure switch since it isn’t cutting off properly.

by Bruce E Schmidt

(Davidson, NC)

We have to replace the air pressure switch on a single stage Farmhand air compressor 60 gal.

The pressure switch has 4 connections on it with plastic hoses and fittings that I haven’t came across before, looks like you have to push on the fittings some how and helped would be appreciated.

Bruce

______________

Hello there Bruce.

Is the question how to use an “instant fitting” rather than how to replace the switch? If so, here’s a “heads up”.

An “instant fitting” is a remarkable device for quickly installing and removing air line. It works this way.

Inside the tube port of the fitting (usually there is one side threaded, and the other side has a hole into which you push the tube) is a metal (usually stainless steel) collet that compresses out of the way as the tube is slid in and by it.

There’s also an “O” ring through which the tube slides to pass through the collet. The collet has “fingers” that point into the fitting.

As the tube passes by them, they are depressed (no not sad, just pushed out of the way) by the tube.

When you try to pull the tube back out, the collet fingers actually lightly pierce the surface of the tube a little, preventing easy removal of the tube.

When there’s air pressure in the tube, it expands somewhat. That makes the tube bigger, and makes the fingers on the collet “grab” the tube even harder, making it almost impossible for the tube to leave the fitting while it’s under pressure.

There will be a slide ring or pressure ring on the outside of the fitting near where the tube is inserted. By pushing this ring towards the fitting you will depress further the fingers on the collet, allowing them to move away from the surface of the tube, and theoretically allowing the tube to be removed from the fitting.

No, don’t do this while the tube is under pressure. Yes, void the pressure from the tube before trying to remove it.

Will removing it be simple? Nope. Over time, the fingers on the collet will stick into the tube, and even aggressively pushing on the slide ring may not dislodge the fingers.

After a while, you may curse the whole concept of “instant fittings”, yet some are better than others, and actually work, even if installed on a charged air tube for some time.

Does this help, or have I answered the wrong question?

Changing pressure switch value.

by John Hill

(Napa Valley, CA)

I want to run two compressors in series. One has a high pressure cut off of 100lbs. and the other 145. I need to lower the 145 to 100 so the pressure relief valve in the smaller compressor doesn’t blow.

I need the combined storage 80gal. and CFM, about 16.5, to run my sandblaster without constantly having to stop to let the pressure come back up.

Is the pressure switch adjustable or if fixed how are they set at the factory?? Any info appreciated. It is a DeVilbiss 60 gal. oiless.

Hi John. I’m not sure that your PRV would blow at 145 PSI, so if that’s the only reason for changing the pressure switch settings, you may not have to. Only one way to find out…right? Test it.

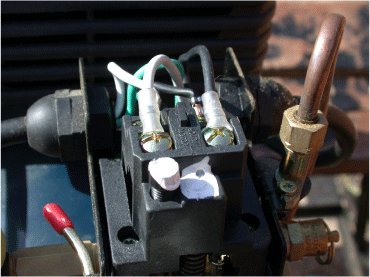

I’ve uploaded a photo of the innards of the pressure switch on one of my compressors.

You can see (actually, you can’t see ’cause they are covered in sealant) at this end there are two nuts. One adjusts the high pressure cut-out, the other the low-pressure cut-in.

They are often sealed, as mine are, so that the factory knows if you’ve been messing with the settings, should you ever need to take your unit in to the shop.

John, you’ll have some plumbing issues to consider when joining two tanks together.

How do i adjust the turn on and turn off pressure of my air compressor?

by leaman

(seattle WA)

Bought the tank used. Tank rated for 120 p.s.i.

I think the prior owner of the compressor messed with the settings. There appears to be / are two adjusting screws.

Hello Leaman, nice to hear from Seattle.

It sounds to me like you’ve already found the device that turns on your compressor at the cut-in pressure point, and shuts it off again when it reaches the cut-out pressure, and that device is the pressure switch.

Some are meant to be adjusted. Others are not.

You say the previous owner “messed with the settings” yet you don’t indicate what the present settings are.

You are correct, if your pressure switch has two nuts on a threaded rod with springs below them, those are the adjusting nuts.

Make sure you pull the plug first.

Look inside the cover to see if there are any instructions printed there.

You should have noted also at what pressure point your compressor cuts-in and cuts-out now. Drain air from the compressor until the pressure setting is below the cut-in point.

Turn one of the nuts tighter (this should increase the setting) 1 turn. Plug the compressor back in, and see what the change has accomplished, and which setting changed. (The cut-in or cut-out level)

Mark on the pressure switch cover which nut is which, and continue adjusting to suit.

Beware that you do not set the cut-out pressure too high. You could have disastrous results.