Everything is working well on the compressor when all of a sudden the line blows off the pressure switch on the compressor.

If you’ve had this happen to your air compressor, the logical step is to push the line back in the hole. That may or may not work. Here’s why this happens and how to fix it.

To better understand why the line comes off the pressure switch, it is useful to know what the line is and how it is attached.

The line to the pressure switch commonly runs over from a fitting on the compressor tank.

The purpose of this air line is to allow compressed air that may be trapped over the compressor piston to escape when the compressor stops. The air that may be trapped over the piston is vented through the compressor unloader valve, and it is the unloader valve that this line commonly connects to.

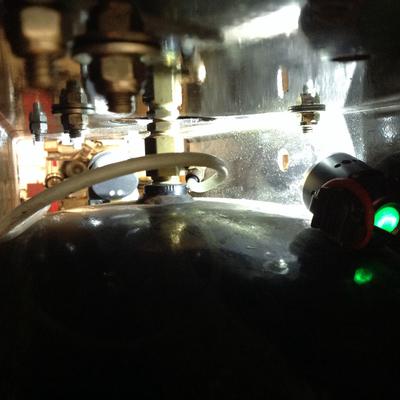

The photo shows part of a common pressure switch with a side unloader valve.

This type of air line is often copper or metal, and normally uses a compression fitting to attach the line. It is not common for this line to self-disconnect from the unloader valve, unless the attaching nut is loose. Reinserting the line and tightening the nut is normally all that is needed should this line comes off the pressure switch.

It is the pressure switch with a bottom-inserted air line that seems to most frequently self-disconnect. This type of pressure switch typically had a hole in the bottom plate into which a plastic air line was inserted. Inside the hole was an instant fitting which was an integral part of the switch and the unloader valve inside the pressure switch.

Over time and with frequent compressor use, the heat generated by the compressing of air would travel throughout the compressor, even to where the plastic air line was inserted into the fitting inside the pressure switch. That continuous exposure to heat would harden the plastic tube. The collett inside the fitting could not longer “grab” the surface of the plastic tube due to this hardening, and air pressure inside the tube would then blow it out of the fitting.

It seems to me, based on the newer design of unloader tube to bottom-connected fittings, that the pressure switch manufacturers have recognized this frequent problem and resolved it by moving the unloader tube fitting outside of the pressure switch – to a cooler area – and one that may allow a more robust connection to the plastic tube. This newer design can be seen in the next image.

Fix The Line Comes Off The Pressure Switch

Knowing why the line blows off the bottom of the switch is fine, but how is it fixed?

Fairly simply, actually. Since there is some slack in almost all unloader tube lines, remove the tube from the pressure switch if it isn’t already off, and cut off about 1/2″ from the end of the line.

This will remove the heat-hardened part of the tube, leaving a fresh, and softer tube surface to be inserted into the fitting, and hopefully to fit snugly and firmly to prevent blow off of the tube.

If there isn’t enough slack in the tube to allow sufficient to be cut off, then it’s time to replace the tube. I don’t recommend that you use poly tube as it may weaken when exposed to the compressor heat. Visit an industrial fluid power supply shop and ask for a length of polyurethane tube, or any other higher heat resistant tube, to be use instead. You should be able to get one long enough (add 6″ so your line has sufficient slack) for a couple of dollars.

Reader Contributions

Plastic hose from pressure switch keeps blowing out

by Ernie

(North Chicago IL)

When my compressor reaches about 80-90 PSI the plastic hose from the pressure switch blows out.

If you look carefully at the photo you can see the plastic tube has ruptured.

Thank you for any help you can give me.

Ernie

____________________________

Plastic hose from compressor blows off

Well Ernie, I looked as close as I could, and didn’t see where it was ruptured.

This air line is normally connected between the tank check valve and the unloader valve.

It looks like it might be a polyethylene or polyurethane line, but I cannot be sure from the photo.

If it’s polyethylene, over time, elasticizers in the plastic have dried out and the tube becomes less elastic. The continual expansion as air moves through it, and the contraction as air is exhausted, essentially wears out the tube.

If it’s polyurethane, the same thing happens, over a longer period.

Thing is, heat is not good for plastic tubes and, it is possible, that this tube has been baked a bit due to heat from the pump.

In any case, it looks like it’s inserted into the tank check valve with a quick fitting. Push the tube into the fitting, depress the black collet around it and then pull the tube. That should release it.

Take the tube to a good hardware store or, better yet, an industrial supplier (google suppliers of air valves or air cylinders in your area to find them) and you should be able to pick up a length of tube of the same dimension to replace this one.

______________________________

Plastic vs Copper Lines

Thanks Bill!!

Can I change that tubing to copper from plastic? I have a bunch of old compressors that don’t have any plastic only copper lines?

Is the fact that the plastic line is blowing out, a sign of a more serious issue orjust that the plastic line is old or not strong enough?

Thanks again!!!

Ernie

_________________________________

I believe copper is better

by: Bill

You bet, Ernie. Copper is better than plastic anytime. It’s not on many compressors now because it costs them more to included a component that will provide long, long life and has higher material cost.

If your PRV isn’t blowing off (you do test it I hope – the PRV page for details), meaning the air compressor is over-pressurizing, then I don’t see it being an issue other than the line is brittle where it enters the fittings, and the fitting isn’t holding it securely any more.

________________________________

Still no answers on why it blew

by: Russell

Replaced plastic tube blew it about 80 psi ,what causes this? Please help need my air

_________________________________

Still no answers on why tube blew out

I have no idea what compressor you have, what pressure switch, how the line is installed in the pressure switch, all would contribute to why you have not received any answers, Russell.

An extremely hot motor can weaken this tube. Heat also makes the end of the tube “case hardened” meaning, if it’s held in place by an instant fitting, the fitting can no longer hold the hardened tube.

If you read the posts on this page it will explain how the air line to the unloader is normally connected.

If you have replaced yours with a new line, either the fitting has failed, or the new air line is under sized. Without more information it is impossible for me to be sure about the cause.

_____________________________

Plastic hose from pressure switch keeps blowing out

Where are you getting replacement hose/tube?

Most of it is rated to less than 100 PSI. You probably need more than that, 150 or so.

As has been mentioned, replacing it with copper tube is your best bet for a reliable fix.

I can’t get the tube out of the quick fitting

I can’t get the tube out of the quick fitting

_____________________________

I can’t get the tube out of the quick fitting

Not knowing what fitting, or what compressor makes it a bit difficult. If you can see the fitting, around where the tube inserts is a “ring”, typically. If you pull out slightly on the tube then push it in tight. Then using two fingers depress the ring and that usually frees up the tube to enable it to be removed from the fittings.

If this doesn’t help, please take a picture of where the tube and fitting is on your compressor, and add it to this thread in a comment. Thank you.

New comment? New question? Please add it here along with photos to help others help you with your compressor and equipment problem!