Those of you who wish to start airbrushing in the near or distant future must ensure you have all the necessary equipment at hand to be able to conduct your tasks. This article will provide you with the must-haves, as well as optional extras and some information on safety while using an Airbrush.

Table of Contents

- The Air Source

- The Airbrush

- The Airbrush Medium & Support

- Additional Accessories

- Airbrush Safety Accessories

- Reader Questions & Answers

The Air Source

Before purchasing your Airbrush, if you haven’t already, you must obtain an air source that has an adequate air supply to power your Airbrush and deliver peak performance. You therefore must consider which of the following 3 types of air sources is right for you:

- Air Compressors

- Air Propellant Cans

- Co2 Tanks

Now let’s take a look at each in more detail!

Using Air Compressors as an air source for Airbrushing

Starting with probably the best air source you could obtain, an air compressor. These are certainly something you should heavily consider if you are planning to conduct airbrushing jobs. The type of compressor you want typically depends upon the type and amount of work you intend to do with it.

Compressors are available with or without storage tanks, they can be low-pressure (less than 150 psi), medium-pressure (150 psi to 1000 psi), or high-pressure (greater than 1000 psi), and, are even available as “silent” compressors rather than making a lot of noise.

When you are deciding on the air compressor you need for your airbrushing tasks, you must ask yourself a few questions! First of all, consider how large of a paint area you intend to airbrush. If it’s very large and you intend to work continuously for 20 or 30 minutes, then you will want an air compressor with a storage tank and a capable duty cycle, so your work isn’t as constantly disturbed by having to wait for the compressor to catch up. If it’s a small area, a storage tank may not be necessary.

For more information on the duty cycle of an air compressor visit our guide!

Do you intend to paint on a body? Then you may wish to purchase a very low-pressure air compressor with a regulator. Or are you going to be spraying cars? If you intend to carry out multiple variations of airbrushing then you must buy a compressor suitable for all tasks!

Another consideration is of course the noise of the air compressor, are you going to be working late evenings when the kids are put to bed early? If so, you may wish to get a silent compressor to avoid the grief you’ll receive from your partner or neighbors! If noise isn’t an issue, then get whatever compressor you like!

Visit our 10 Best Air Compressor For Airbrush guide to help you pick the perfect compressor.

Advantages of Using an Air Compressor

Air compressors (along with regulators and pressure switches) allow you to control pressure which can be useful when different tasks require different tasks. Compressors are widely available, they have silent options and are cheaper in the long run.

Disadvantages of Using an Air Compressor

The only downfall of air compressors is that they can of course be noisy if you do not get a silent one. Another thing to note is that if you purchase a tankless compressor, your airflow will be subject to fluctuations. Having an air tank on your compressor will allow the compressed air to smooth out and be regulated at the desired pressure. For more information on Tankless Air Compressors visit our guide!

Another key disadvantage of using air compressors is that you will have condensation build-up within the airlines and if you don’t use a water separator or moisture trap, this could significantly affect the quality of your work.

Using Air Propellant Cans as an air source for Airbrushing

Airbrush air propellant cans have a relatively limited capacity but are compact and silent options. If you intend to use your airbrush frequently then this option immediately becomes expensive. Air propellant cans are suspected to provide you with 10 to 15 minutes of operation, indicating how this may not be the cheapest option if you have a lot of work to conduct over a period of time.

They are, however, extremely easy to use so any airbrush beginner can pick them up and use them without difficulty and save the initial cost of buying an air compressor and learning how to use one of them. If you plan to paint models then you should expect to be able to paint maybe 1 or 2 depending on their size and coverage. I personally, would recommend investing more money in an air compressor for the long term (and not to mention the masses of other tasks the compressor will enable you to carry out).

Advantages of Using Air Propellant Cans

The only real stand-out advantage is the fact they’re so easy to use, and that they’re a great way for beginners to get started.

Disadvantages of Using Air Propellant Cans

Of course, their limited capacity can quickly become an issue, they don’t last long at all which will lead to you having to spend a lot of money on multiple air propellant cans. The air pressure of the cans is not the best and it decreases as you use the can which can affect the quality of your work.

Using Co2 Tanks as an air source for Airbrushing

Co2 tanks are another viable option, and better than air propellant cans as they are capable of operating at higher pressures and can be refilled. Co2 tanks don’t require electrical power like air compressors and work in a very quiet manner.

The size of the Co2 tank needed for carrying out airbrushing jobs can be as low a 5 lb for small jobs like painting plastic models or up to 100 lbs for large jobs. You may even need greater tanks for tasks like painting t-shirts as you will need additional air storage.

The cost of refilling these air tanks will vary, you should expect to pay within the regions on $10 to $30 to refill a small 5 lb Co2 tank. I have no doubts that it will be possible to refill your Co2 tanks at a local store so have a good research online or contact one of your local hardware stores.

When buying Co2 tanks online, they tend to be shipped empty, and then you’re tasked with filling them or exchanging them for full ones to avoid the safety hazards of shipping Co2 tanks.

Now, you might wonder how long would a Co2 tank last? Typically on average, a 5 lb Co2 tank will allow you to paint 5 or 6 plastic models, depending on their size of course. 5 lb Co2 tanks will last for around 5 hours of continuous airbrushing in the range of 20-25 psi.

There are some safety concerns you must be aware of if opting for Co2 tanks because they have the potential to be dangerous. Without sufficient fresh air ventilation, the Co2 confined to your work environment will displace the oxygen and lead you to find difficulties in your breathing as well as making you tired, and potentially even passing out!

Another concern is their transportation, they must be carefully transported and positioned so that they’re not dropped or fall over. It’s generally advised to securely chain or block the Co2 tank in position when you are or even are not using them.

Co2 tanks are great for portability, allowing you to work wherever you want, away from noise-sensitive areas but because of their size and weight, they’re not ideal for working from home.

Advantages of Using Co2 Tanks

The key advantages of using Co2 tanks are that they’re silent, have no condensation build-up, and can operate and both low and high pressures. Their portability and no need for a power source allow you to use them outdoors or wherever you fancy.

Disadvantages of Using Co2 Tanks

Co2 tanks have many disadvantages however, they’re heavy, they’re dangerous, they need to be refilled and the cost of the refill will quickly add up making them more expensive in the long run compared to air compressors. It’s possible that the gauges can freeze if you’re using the airbrush for a long period of time, and the need to add a dual gauge can also be quite expensive.

The Airbrush

Airbrushes are tremendous tools that can enable you to conduct many different tasks including model making or fashion design, cake decorating, car painting, and even make-up! What you really must ask yourself is what do you intend to use the airbrush for?

Selecting the airbrush itself is of course a very important decision. There are many variations including single-action, double-action, gravity-feed, and siphon-feed. Each has its own characteristics which make them suitable for different applications.

You don’t need the same type of airbrush for airbrushing models as you would for fashion design. You must first identify the type of work you will be using the airbrush for and then make a decision based on that. I’ll always advise investing more money in a reputable brand to get a high-quality airbrush rather than a low-end one. This will enable you to have access to replacement parts if necessary more easily, and for sure will provide you with better quality work.

Cheap low-end airbrushes will be made from cheap and poor materials that are likely to break or cause you a shear amount of frustration when working. For more information on airbrushes and how they work, visit our guide here!

I have picked out the following airbrushes available on Amazon. The first is a standalone Dual-action gravity feed airbrush, and the latter a full airbrush kit, which includes a dual fan air compressor and 3 different airbrushes.

- Professional Master Performance Multi-Purpose Model G233 Pro Set Master Airbrush. The Pro Set is a Model G23 precision dual-action gravity feed airbrush with 3 nozzle set sizes (0.2, 0.3 & 0.5 mm needles, fluid tips and air caps) and has a 1/3 oz. gravity fluid cup. Airbrush kit also includes a 6 foot braided air hose with 1/8 fittings

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- Professional Master Airbrush Multi-Purpose Airbrushing System with 3 of Master Airbrushes best selling & user friendly airbrushes. Includes bonus Master Airbrush Quick Start Guide and Airbrush Resource Center access card.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

The Airbrush Medium & Support

The airbrush medium you need is the type of color liquid material that you can spray with the airbrush. In most cases, the medium is painting, any of the following:

- watercolor paints

- acrylic paints

- oil based paints

- gouache

- inks

- urethane

- food coloring

The key to a successful airbrush job is using the correct medium for the or combination of mediums for the surface you’re spraying onto. You can spray on almost anything, from wood to paper, or skin to canvases, just ensure the medium you use is compatible with your surface. Some examples of the support or surfaces include:

- T-shirts

- Automotive surfaces

- Airbrushing on leather

- Skin

- Cake

- Wood

- Paper or cardboard

All paints must be prepared, or thinned, to the correct consistency before they can be used in an airbrush otherwise you risk the potential of clogging your airbrush, now, you don’t want that if it’s brand new! However, many manufacturers now provide airbrush-ready paint to save you this step and risk.

You should be able to pick up your required paint at any local hardware store, or if you know what you want, conduct an Amazon search! Here is an example of some acrylic airbrush paint readily available on Amazon.

- 1. The set contains 24 professional colors: BLACK, WHITE, CRIMSON, LIGHT PINK, LEMON YELLOW, BLUE LAKE, MID GREEN, PURPLE, ORANGE, BROWN, AQUA BLUE, PHTHALOLYANINE GREEN, PHTHALOLYANINE BLUE, BURNT SIENNA, FLESH COLOR, LIGHT MAGENTA, NAPLES YELLOW, GOLDEN, PEARLY SILVER GRAY, PEARLY PURPLE, PEARLY WHITE, FLUORESCENCE SCARLET, FLUORESCENCE ROSE, FLUORESCENCE YELLOW.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Additional Accessories

Finally, there are some accessories that you should consider purchasing when you intend to start airbrushing. Some are of course optional and depend on what air source you use but others are absolutely necessary to ensure that your work is at its highest standard.

Air Filter, Moisture Trap & Water Separator

It’s very important to ensure that your airbrush is supplied with clean dry air so that the paintwork is protected. Water or other contaminants can easily get into the air stream and so you must insert either an air filter, moisture trap, or water separator into your lines.

Without air filters or water separators, condensation can easily build up in your airlines and shoot through your airbrush, airbrush, and directly onto your work surface which can significantly affect the quality of work.

These components are readily available and easy to install into your airlines! Here are some examples of products readily available on Amazon.

- Max. Supply Pressure: 250 PSI, Max Operating Pressure: 140 PSI, 50 SCFM @ 90PSI

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- Recommend Regulating Pressure Range: 30-120PSI.Max Regulator Pressure: 130PSI

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- Automatic drain for removing accumulated liquid from a compressed air system

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Air Hose

An air hose is absolutely necessary to connect your air compressor to the airbrush. The aim is to purchase an air hose that is long enough to cover the distance between where your compressor is located and where you wish to use your airbrush. For information on The 10 Best Air Hoses visit our guide here!

You will also need to purchase couplers and plugs to be able to connect your air hose to your airbrush. These will typically be in NPT (national pipe taper), the standard for pipe fittings in the US, or BSP (British standard pipe) for standard fittings in the UK. For more information on Air Hose Fittings Types, visit the guide to air compressor coupler types here!

- POLYURETHANE CONSTRUCTION: No tangles, anti kinking, abrasion resistance, durable and light weight.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- Includes 3/8” x 25 ft air tool hose and another 18 pieces essential air compressor parts

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Along with the air hose and its fittings, quick release, connect or disconnect, fittings are desirable. Quick-connects allow you to connect and disconnect your airbrush from your air hose with ease. Not only can quick disconnects be used between the compressor and the hose, but also from the hose to filters or regulators, and filter or regulators to the airbrush.

If you are likely to be swapping between different types of airbrushes then quick-connect fittings are ideal. They work simply on a spring-loaded mechanism that allows the male end (tail) to detach from the female end. The female end is normally attached to the airbrush hose and the male end is attached to the airbrush, but it may be possible to have the reverse.

- I/M type air fittings with 1/4NPT threads.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Airbrush Pipettes

Airbrush pipettes are great tools to use to transfer small amounts of paint into the airbrush cup. Pouring the paint into the airbrush can potentially get messy and so, using a pipette will provide you with accuracy and save wasting any paint. Pipettes are also useful for mixing paint.

- These inexpensive, disposable plastic eyedroppers are just the right size for putting small quantities of paint into your airbrushs paint cup

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Air Regulators for Airbrushing

Air regulators are important components to allow you to control the air pressure coming from the air compressor. Some tasks will require varying pressures and so, installing a regulator need the end of the compressed air system line can allow you to adjust the pressure depending on your requirements. Here is an example of an air regulator readily available on Amazon.

- Locking air regulator for precisely regulating and maintaining constant air pressure

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

I have also picked out this combination unit, which is a regulator and water separator. It may be useful to have only one attachment to your line rather than two!

- BRASS FILTER ELEMENT - Filtering moisture and fine particles to get clean and dry air which prevents damage to air tools, spray guns and pneumatic equipment. The filter element is brass that provide higher efficient filtration and long lifetime than the fiber one.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

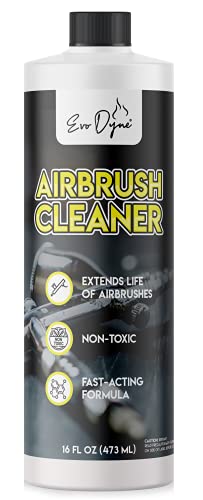

Cleaning Materials

It’s necessary to purchase some cleaning materials and this should be seen as a basic piece of equipment along with purchasing the airbrush itself. You must think about getting the appropriate cleaning agent that is suitable for the type of paint you are using as well as considering getting basic Q-tips, pipe cleaners, and brush cleaning sets.

Conduct thorough research on suitable cleaning products for the type of pain you’re using and ensure you have them on hand. You could also purchase a cleaning station which will allow you to keep your workspace clean when needing to flush the airbrush with cleaner. It’s essentially a closed container with a rubber hole where you insert the airbrush nozzle. Below are a few products readily available on Amazon, first of we have this Airbrush cleaner, followed by a Master airbrush cleaning kit which includes the cleaning container, needles, and brushes!

- Airbrush Cleaner: The Large 16-oz Evo Dyne Airbrush Cleaner is an Artist’s Best Friend & ideal for removing airbrush paint (s) in seconds! Our Extra-Strength Formula works great as a general-purpose cleaner for any artist working with Acrylics, Watercolors, Gouache, Inks, Dyes & more!

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- TCP Global Brand 11 Piece Cleaning Kit with a 5 Piece Mini Cleaning Brush Set, 5 Piece Mini Cleaning Needle Set and a Airbrush Resource Center Link Card

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Cutting Mat & Hobby Knife

A cutting mat may be necessary if you are into model making. Cutting mats provide a very long-lasting, non-glare surface that will allow you to cut and slash work without leaving any marks, saving you from damaging any other potential surface.

Again if you’re into model making, a hobby knife or cutting knife will allow you to get precise and detailed cuts on a wide array of materials. The work will include delicate cutting, detailing, stripping, and trimming. Both are readily available on Amazon for purchase.

- 【SEWING CUTTING MAT】Aneuzs self-healing cutting mat protects your work surface. Compatible with rotary cutters and straight blades, wont hurt the cutter blade and keep the blade sharpness. Ideal for artist, crafters, quilters, engraver and hobbyists

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- 16 piece premium precision knife set for various hobby, craft & professional uses

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Airbrush Safety Accessories

Health and safety is a very important factor to consider when operating any tool or device. When using an airbrush and spraying paints, it’s possible that you might inhale paint particles which could be harmful to your lungs and health.

It may be necessary to obtain a suitable breathing respirator so that when you airbrush leather dye, for instance, you are able to avoid the poisonous dye from entering your lungs. If you’re using any solvents, enamel, or lacquer paint you must have a respirator that offers protection from organic vapors.

Please do not use any old face mask and think you’ll be okay because you won’t. They are pretty much useless in this situation. Airbrush respirators have a full mouth and nose cover that creates a proper seal around your face. They also tend to come with filters that can be replaced to ensure that it doesn’t get clogged and stop working. Look out for the replaceable masks and try to avoid the disposable ones. The filters will fill with paint rather quickly and the cost of the filter replacement is a lot cheaper than a new mask.

- Sealed & Comfortable: The sealing edge is made from food-grade elastic silicone gum, which fits the face well, provides you with a comfortable wearing feeling. This paint mask strap belt can be adjusted to fit for most head size, designed for tight and comfortable wearing.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

You may also want to invest in, or create, an airbrush booth so that you can avoid messing up your workspace. You could create one from cardboard, or you could purchase the ready-made booths which include the ability to extract and control the paint mist.

Reader Questions & Answers

Getting Started With Air Brushing

Airbrush question: Can I use a l2 volt, 250 psi air compressor with an air brush? If so, what should I purchase?

Answer: Yep, you can. Will it work? Probably not!

There is a correlation between compressor size and compressor use. If you don’t match the two, you won’t be happy.

Your 12 volt compressor is, I suspect, the type used to pump up car tires and is powered by an accessory adapter from the vehicle? Yes, it can provide air up to 250 PSI, but at an excruciatingly slow flow rate. The flow will most likely be inadequate for an air brush.

So, once you get the size of the air compressor right based on the flow and pressure demand of the air brush, that will narrows the choice for the right type of air compressor for your air brushing needs.

Visit the site map page and take a moment to read about Sizing an air compressor for more details, if you wish.

Airbrush question: How to drain the water in reservoir? My son received an airbrush compressor for Christmas and was wondering how to drain the water in reservoir? He says there is no draining mechanism. What are other ways to drain the water? Are all compressors different in ways to drain the water or are they the same?

Answer: I don’t know the model or the make of the compressor so I can’t tell you for sure about your son’s airbrush compressor.

Compressors with tanks or reservoirs have to have a method of draining the tank, as water is always a by product of compressing air, and water will eventually fill an air tank if it is not drained regularly.

Most tank drains are located on the bottom of the lowest part of the tank, allowing gravity to do its work in letting the water flow to a central spot where it can be most efficiently drained from the tank of water when the drain is opened. I wonder if the compressor your son has even has a reservoir. Some models of air brush compressors are demand type, meaning they supply the air right from the pump to the brush, and there is no reservoir of pre-compressed air to draw from.

If there was no manual with the compressor, Google the manufacturer’s name and pose the question to them as well as downloading or requested the manual. You’ll need the manual again in time, I’m sure.

Airbrush question: Airbrush diaphragm compressor regulator valve does not adjust properly? The regulator valve will only stay at 30 psi if i turn it down the air dies. then i have to turn it back up. it is for an air brush set up so i need low air flow, what would the problem be or can i even fix this problem?

Answer: let me get this straight. You have the regulator set for 30 PSI, and when you are using your airbrush, the air pressure supply drops quickly?

A few questions of my own need to be answered for me to help with your air brush compressor problem.

- Does your air compressor turn on?

- What is the uppermost pressure that your compressor can produce?

- What size is the compressor (HP) and what is the flow required of your airbrush, at the 30 PSI it requires?

While there is a connection between PSI and flow, normally a regulator is sized for the compressor and the flow expected. Dialing down the pressure on the regulator may momentarily affect the flow, but typical flow rates for that compressor should be achieved at whatever pressure setting the regulator is set for.

If at the low pressure setting necessary for the air brush, if the flow at that pressure is too high, then an in-line needle valve should be installed before the regulator, which will allow you to adjust the flow to the regulator, and reduce the flow at the correct pressure setting after the regulator and to your paint brush.

Airbrush question: Can I use a non-airbrush compressor for air brush painting? Can I connect an air brush to a 150psi porter cable air compressor? (construction grade air compressor)

Answer: There are a few issues you want need to deal with if using a larger compressor, but essentially the answer is yes.

You first need to determine the pressure and flow requirements of the air brush. Then you will regulate the pressure to the correct pressure level. If the flow rate from the larger compressor is too great, put a needle valve in the line before the gun but upstream from the regulator to throttle the flow to the correct levels for the paint gun.

If the compressor is oil lubed, you may want to look at the coalescent filter section on this site for information regarding removing oil from the air stream. This will be even more important if the compressor has been used for some time, as older reciprocating compressors often add more lubricating oil to the air stream than newer models.

You do want to look at the filter section on this website for sure. All compressors generate water, and you will want to remove water from the air stream to prevent fish eyes.

And then there is the noise. The non-airbrush compressor will likely be much louder than a typical air brush compressor, so you will have to deal with that issue as well.

Airbrush question: Getting Started With Air Brushing? I want to get into air brushing models, 1:72 or 25mm scale. I use water colours, Tamiya, Citadel, Armoury, etc. I’ve been eyeballing the Badger 360 and the Renegade series air brushes but I’m unsure about the compressors. I’d like it quiet and oil-less and I’ll only be using one or two airbrushes at a time. If I go with an oil lube compressor what will I need to keep the air clean going in and comming out of my tank?

So where do I start? Can we talk a little about airbrushing area set up, hoods and ventilation as well. What do you recomend?

Answer: I don’t air brush. I do use compressors, and have worked with compressed air for many years. Here are my thoughts on your questions.

You can use any air compressor that gives you the compressed air flow your air brush needs and the pressure level that air gun demands.

Some compressors are louder than others, and the differences in sound levels are immense. Usually, the quieter the air compressor, the more expensive it is.

All air compressors generate water, and that water, flowing out your air brush, will fish-eye your paint job, so you want to remove water from the air stream. Please read the page about compressed air filters on this site for more information on how to do that.

Oil lubricated compressors will ALWAYS put some lubricating oil into the air stream. Less if the compressor is newer and little used, more as the compressor wears in and seals start to let go. If you used an oil lubricated compressor then, I would strongly suggest that you consider a COALESCENT FILTER to remove oil from the air stream, as that oil will also “fish eye” your paint job. See the page on coalescent filters on this site for more information about them.

As to paint hoods and so on, that’s well outside of the purview of this compressed air site. You would need to talk to the paint suppliers about how one protects oneself from negative issues with the paints they recommend.

If you have any questions regarding the airbrush equipment list or how to start airbrushing, please leave a comment below, with a photo if applicable, so that someone can help you!