A circuit breaker is an electrical switch designed to protect an electrical circuit from the excess current which will result in damage. In simple terms, its function is to detect faults and interrupt the flow of current. When circuit breakers trip, they shut down the air compressor system, and work stops.

It can be a problem when the circuit breaker constantly shuts down your air compressor. This page will provide you with the reasons why your air compressor keeps tripping its circuit breaker as well as provide you with existing reader questions and responses.

Table of Contents

- How An Air Compressor & Circuit Breaker Work Together

- Why An Air Compressor Keeps Tripping The Circuit Breaker

- Air Compressor Blowing Power Supply Circuit Breaker vs Motor Thermal Overload Switch?

- FAQs (Frequently Asked Questions)

- Reader Questions & Responses

How An Air Compressor & Circuit Breaker Work Together

When the air compressor tank is drained down to the cut-in pressure, the pressure switch will react to this drop-in tank pressure. The pressure switch trips to passing and allows the compressor to start and run until the compressor tank pressure has reached its cut-out pressure.

When the pressure reaches the cut-in, the current of electricity will flow through the pressure switch and then through the motor to start the circuit and then flow to a start capacitor to kick start the system.

Note: some small compressors may not have a start capacitor as they have sufficient current in the electricity flow to start the motor but larger compressors will require this additional “inrush current” of the start capacitor.

If for some reason the motor cannot start on your compressor, it will continue to draw power and may even pull enough amperage to exceed the capacity of the circuit breaker and as a result, the circuit breaker will trip.

Why An Air Compressor Keeps Tripping The Circuit Breaker

- The air filter

- Broken extension cord

- Clogged cylinders

- Faulty circuit breaker

- Faulty motor

- Faulty pressure switch

- Failed capacitor

- Failed unloader valve

There are a number of reasons why an air compressor circuit breaker trips. Let’s take a look at each in more detail!

The Air Filter

Air compressor circuit breakers are liable to trip due to a dirty air filter. Air filters prevent dirt from entering the air pump, as dirt inside can result in expensive repairs. It is therefore important that you change your air compressor filter often to avoid this.

If your air compressor circuit breaker trips and you check your air filter and it is dirty, replace it and try again! If your compressor still trips, you will need to troubleshoot further.

For more information visit our compressed air filtration guide!

Broken Extension Cord

Most air compressors are powered by electricity and therefore feature extension cords to easily connect to power supplies. A broken extension cord can cause some serious risks, potentially even fire. A fault in an extension cord will trigger the circuit breaker to trip and cut off the electric supply to the compressor and shut down its system.

Extension cords are notorious for throttling power, and therefore you may be underpowering your compressor motor. This will contribute to the motor overheating and the air compressor breaker tripping when the compressor starts.

You should leave the compressor to cool for between 15 and 30 minutes, then plug it directly into a wall socket rather than an extension cord. If your compressor starts this time and you have used it until it needs to restart, and it does so successfully then you’ve solved your problem.

Visit our What Size Extension Cord For An Air Compressor for the best extension cords available.

Note: I will always advise that you use a lengthy air hose to get your compressed air to your desired workstation. Using an extension cord to get the air compressor closer to where you require to use it is likely to result in damage whilst a lengthy air hose will not.

Clogged Cylinders

It’s possible that the cylinders inside your air compressor (if it has any), can become clogged and hinder the performance of the compressor. A faulty or clogged cylinder or multiple can certainly cause the circuit breaker to trip to prevent the air pump from undergoing damage.

Faulty Circuit Breaker

Let’s not ignore the fact that the circuit breaker itself could be faulty! Though they’re very high-quality parts installed in air compressors, it is possible that after years of use, they become faulty.

They’re very easy to source and replace if this is the case, allowing you to restore the correct functions of your air compressor system.

Faulty Motor

Air compressors feature high-capacity induction motors that have a low amperage draw. If you have a faulty motor it can trip the circuit breaker in your air compressor system. The motor windings or any other electrical connections inside the motor may be shorting and this sudden flow of electricity pulls too many amps.

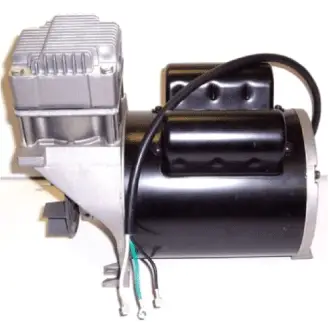

You will probably need the services of a specially trained technician to determine whether you have a faulty motor or not. We have an air compressor motor guide that provides types of motors and where to buy them!

Faulty Pressure Switch

Though this isn’t as likely as the other reasons why a circuit breaker trips, it’s still possible! When the air pressure in the tank drops, a small diaphragm inside the pressure switch moves and forces points inside the switch to touch making a circuit. This then signals a flow of power to the compressor motor to enable it to start and pump more air into the tank.

To check if your pressure switch is faulty and causing the air compressor breaker to trip, follow these steps:

- Turn off/unplug the compressor and drain its tank of air

- Pull the cover off the pressure switch (be careful due to the presence of live terminals)

- Reset the air compressor breaker

- Watch inside the pressure switch to see if there is any arcing or sparking when you turn on the compressor

If any arcs or sparks occur when you turn the compressor back on, that’s a great indication that your pressure switch needs replacing.

Failed Capacitor

If your compressor is large enough and has a start capacitor, it’s likely that your circuit breaker trips due to the failure of the capacitor.

It’s a very complex process to test an air compressor start capacitor and therefore you should seek professional help to do so!

Failed Unloader Valve

Sometimes the unloader valve can fail and cause the circuit breaker to trip. When it fails, compressed air will become trapped over the cylinder piston and this adds to the load the compressor motor experiences on startup. The additional load may force the motor into pulling too many amps and therefore tripping the circuit breaker.

To test your unloader valve, follow these steps:

- Turn off/unplug your compressor

- Open the tank drain and drain all the air out

- Turn on/plug your compressor back in with an empty tank

If your air compressor starts and the circuit breaker doesn’t trip after doing this then it’s evident that your unloader valve is not working properly and it either needs fixing or replacing.

Air Compressor Blowing Power Supply Circuit Breaker vs Motor Thermal Overload Switch?

The key difference between an air compressor blowing the circuit breaker and the motor thermal overload switch is that the latter is solely due to the compressor motor overheating, and so, the thermal overload triggers and doesn’t allow the compressor to turn on until it has sufficiently cooled.

On the other hand, the circuit breaker may trip due to the many reasons described in this article!

FAQs (Frequently Asked Questions)

There are so many different reasons why your air compressor is tripping your circuit breaker. These include a dirty air filter, broken extension cord, clogged cylinders, faulty circuit breaker, faulty motor, faulty pressure switch, failed capacitor, or a failed unloader valve.

Yes, if your compressor goes bad and tries to draw too much electricity it will certainly trip your circuit breaker among other possibilities. You must aim to keep all your compressor parts in good working condition to try to avoid a tripping circuit breaker.

There are a number of reasons why this may occur, it could as simple as having a faulty motor or even a faulty circuit breaker itself. Otherwise, the air filter could be full of dirt and clogged, and the unloader valve or start-up capacitor could be failing and consequently cause the circuit breaker to trip.

Reader Questions & Responses

Motor Trips Break After 5 Seconds

Question

Emerson electric motor label, could this problem be caused by the running capacitor?

Response

Mike, you are not giving us much to go on.

Are you running your compressor motor in a 120 or 240-volt configuration?

Does the compressor run if the air tank is empty when you start it?

Are you using an extension cord if running the compressor on 120 Volts?

How old is your compressor?

What is the make, and model?

Sure, it could be the capacitor, and you can see the page on this site about how to check that.

Otherwise, it is difficult to say without a lot more info. Please add more info so we all can try to help.

4hp 13 gallon Air Compressor Trips Breaker

Question

Got a 4hp 13-gallon oil-less air compressor the problem is that it builds air fine but when it gets low on air and tries to kick back on it just hums and trips the breaker any clues? the motor I’m guessing? please help

Response

Jill, turn off the compressor. Drain the tank. Turn the air compressor back on. Did it start OK? Respond as a comment here, please so if it did not start we can dive further into the reasons.

Air Compressor Will Not Restart and Trips Breaker

Question

My air compressor will not restart after the first start-up cycle. I’ve changed the pressure switch with a new unloader valve. I’ve changed the check valve. I’ve tried multiple higher-amp ac circuits. The compressor acts the same after the first cycle of pressure in-tank it tries to restart after low-pressure level trips, and the compressor tries to start and eventually trips the compressor breaker.

Response

OK, you don’t say after you changed the pressure switch (probably not needed) and unloader valve, whether when the compressor comes up to cut out pressure and stops your unloader valve actually is unloading the compressor.

You also do not describe your power supply to the compressor, nor its make & model and HP.

It is hard to help you diagnose the problem without these details.

So, if the compressor starts with the tank empty of air, and the unloader valve is working on high pressure cut out, provide more details as a comment here and I’ll try to help you figure out what the problem is.

30-gallon Craftsman Blows Breaker

Question

Started the other day kicked the breaker found a bad capacitor, changed it, and now the compressor runs for a few seconds then kicks the breaker.

Response

Model number? How many caps are on this motor? Is anything new aside from the problem? Perhaps, start a new thread in the Craftsman forum, and include the model number for sure, along with any more info. Thanks.

Compressor Motor Blows Breaker

Question

Bill! The compressor is a Black Hawk 5 HP as I recall, Running on 120V. I took the belt off the pump just to make sure the pump wasn’t holding it back. even without any resistance, the motor blows the breaker after a few seconds…Mike

Response

Hi Mike… OK Black Hawk I believe, don’t believe it’s a 5HP if you are powering it with 120 volts.

Regardless, if you are not using an extension cord and the problem persists with no load on the motor, then yup, the first thing to look at is if the start and run (might be two – might be two in one) capacitors are OK. See that page for details and then update us if that was the issue, would you?

Fortress 27 Gallon Model FT27200 Air Compressor Trips Circuit Breaker

Question from John

I have a Fortress 27-gallon model FT27200 compressor. I’ve been using it on and off for months but started using it recently more often. In the middle of use, it tripped the house circuit breaker.

If I try to turn it on it’ll shoot a few sparks from the motor housing and try to run for about half a second or less before tripping the breaker. I’ve tried it with an empty tank and no change. I’ve also tried different outlets and circuits, and the same problem. Nothing else is plugged in. What could be wrong with it?

Response from Doug in s.d.ca

Is this the same as the HFT tem# 56403?

If so, it looks like the motor has a commutator, and therefore brushes, which would explain the sparks. If present, they are either stuck or worn out.

If that’s not the case, please send some pix of the machine and the motor.

Common Tripping Breaker Fix

The electrical tidbit here. Here’s a fix to try for a compressor tripping the breaker.

If your breaker trips shortly after the motor kicks in you might want to try replacing your standard compressor breaker with a ‘high magnetic’ breaker.

A ‘high magnetic’ breaker has a delayed trip to allow for the high current draw when an electric motor starts.

Changed my standard 20A breaker to a high magnetic breaker and my tripping problems went away. They are not sold in home centers or hardware stores. Got mine from Grainger.

Hope this helps.

Most importantly, what Bill said before you work on the compressor or panel “Make sure the power supply is off!”

Twin-Cylinder Air Compressor Blows Motor Breaker

Question

What’s going on with the air compressor when the compressor blows the motor breaker? Here are some questions and responses about compressors that blow the motor breaker. I hope they help.

I have been through all the test cases with the unloader valve and the check valve and all is fine with these components. I have narrowed my problem down to this.

My twin-cylinder air compressor restarts at the cut-in where the motor struggles and the compressor motor lopes between the start and run and then the motor breaker cuts the motor off.

I have a pressure safety check valve in the air tube running between the two cylinders. If I pull this pressure valve out when the motor starts at cut-in then the motor starts up and running fine and when I release the safety check valve it will continue to run to the cut-off pressure. There seems to be some type of pressure imbalance that builds in the air tube between the two cylinders.

The reason I say this is because if I block one of the intake ports on one of the cylinders then the motor starts right up and the compressor starts running fine then I can unblock the cylinder port and it will continue to run to the cut-off pressure.

However, every time I let the compressor restart without either releasing the safety valve between the two cylinders or blocking one of the intake ports the motor struggles to get the compressor running between the start and run and the motor breaker cuts off after about 2 seconds or so.

What could my problem be???

Response

It might help all of us to know what makes and HP of the compressor.

What my thoughts are is that the intake valve on the second cylinder may be impaired somehow, creating back pressure in the line between the two, and essentially, overloading the compressor motor on startup.

Another Compressor Hums Then the Breaker Pops

Question

Every time I try to start my air compressor it hums then the breaker pops. I have taken the cover off of the back and turned the fan wheel and can hear the cylinder popping but won’t start while plugged in.

Response

Turn it off, drain all the air from the tank, and then try to turn it on again. Any change?

Question

I have used all the air up. There is no air in the tank. The compressor won’t start to build up any pressure.

Response

I asked you to do the drain-the-tank thing as that simulates the operation of the unloader valve. Air trapped over the piston can overload the motor on startup, and cause your compressor symptom.

So, next, any change in the power supply Dan, stop using an extension cord if you are, and make sure nothing else is pulling power from the same circuit your compressor is on at the same time it’s trying to start.

If that’s all good, make sure your intake filter is clean, and then, it’s time to check your capacitor. See the how-to check the capacitor page on this site.

My Campbell Hausfeld Air Compressor Motor is Getting Hot and It’s Kicking Breaker Off?

Question

I have a Campbell Hausfeld 80-gallon air compressor and the motor went bad. I replaced the motor with the same horsepower motor. About 8 months later the compressor went bad but instead of replacing it with the original 5hp compressor, I replaced it with the 7hp compressor.

Since that time in the summer went by, it is warm if it turns on more than twice in about 30 minutes then the motor will get hot and kick the breaker off.

Do I need to upsize the electric motor to a 7.5hp or is there something else I can do?

Response

David, let me ask you something.

If you can lift 100 lbs. comfortably and you are asked to do so, you do it, and you don’t strain any muscles in the process.

If, on the other hand, you are requested to lift 120 lbs. you maybe can still do it, but now you are overloading your muscles, straining them to lift that heavier load, and you are going to suffer consequences like becoming overheated, running out of energy, perhaps tearing muscle tissue, etc.

To put my metaphor back into context, If I understand your post correctly, you now have a compressor that is built to be powered by a 7.5 HP electric motor, and you are trying to run that 7.5 HP requiring pump with a 5 HP motor. Is that correct?

Then what you are trying to do is have the motor lift the 120 lbs. with muscles that are built to handle 100 lbs. safely, effectively, and for ongoing use.

As a result, I expect you are destroying the 5 HP compressor motor, and I suspect won’t be long before you have to replace it.

And when you do, yup, make sure the motor HP matches the demands of the pump, or you are buying into ongoing air compressor maintenance problems, as far as I see it, anyway.

VT623300AJ Campbell Hausfeld Runs Slower then Trips Breaker and Stops

Question

But when I removed the belt, the motor runs without tripping the circuit breaker. would this still be a starter capacitor problem? if so, please explain. thanks.

Response

Your motor may have two capacitors or one that does both jobs – start and run.

If either is failing the motor will run hot if it starts.

The motor itself may be suspect.

One check to try and determine what has failed is to check the capacitors to take them out of the equation. See that page on this site for help in so doing.

By disconnecting the motor from any load, you reduce the inrush necessary to start the motor, and it runs. Add the belt, you increase the load, and the motor cannot start against it as, I suspect, the start capacitor cannot deliver the added power to get the motor going.

Question

Thanks! I replaced the starter capacitor and all is well again.

My Campbell Hausfeld WL506208AJ Trips Breaker and Quits Working. Why?

Question

The motor starts then after about 5-seconds trips the circuit breaker.

The pressure gauge will be about 50psi.

This is a 120vac 14amp motor. I have moved it to other breakers including my new addition to the house which is a 20-amp circuit and nothing else on it. Any suggestions? Thank You.

Response

Michael, thanks for the info you provided. Knowing that you have checked the power supply helps.

Try this, please. Unplug the compressor, open the tank drain, and allow all the air to escape. Close the drain and plug in/turn on the compressor.

Does it start and run?

Question

Hello, It is a dual-tank model so each tank has a drain. I opened both drains. Nothing came out so I blew into the top tank drain and felt air coming out of the bottom tank drain.

After closing both drains I turned them on. The motor started and filled the tanks. The psi gauge filled to 145psi and then stopped. The breaker did not trip. All seemed fine.

Then I attached my air ratchet and started using it. I noticed the psi gauge dropping then the motor started to hum but the compressor was not working. All I hear was the hum of the motor. After about 5-secs the breaker tripped. Thank you.

Response

I think, based on what you have written, that your unloader valve may not be functioning. Read the UNLOADER VALVE page for details.

Question

The unloader valve pages seem to describe the function of the valve. Should I be looking for pages to troubleshoot the valve? Not sure if I should be servicing the valve or replacing it. Thanks Again

Response

Yes, but is the compressor unloader valve working? In other words, when the compressor stops, does the unloader valve dump the air over the piston, or not? If it does not, that is likely your problem. Then you can either try to fix the unloader or more easily, replace it, though the latter will be more expensive as other components may have to be purchased along with the new unloader.

Harbor Freight 65903-2VGA Trips the Breaker

Question

I have read all the relevant posts and I kind of have the idea that it is my motor…

I have a secure connection to the wall with no extension cords and I hired an electrician to install the proper source.

Out of the box the compressor built pressure for 20 seconds and then tripped its compressor breaker. I press the reset button and it works for 20 more seconds or so. Technically, if I wanted I could do that over and over until I acquired proper pressure, but something tells me that that is a bad idea.

If I install a new motor on it (which I am capable of doing, I think) which one should I get? And how am I certain that the pressure switch and breaker are connected properly?

Before I buy a new motor though, could it be the check valve or pressure switch malfunctioning? After all, those are quite a bit cheaper… and for a cheap compressor in the first place, what a pain…

Thanks, Johnny

Response

Hello Johnny, and thanks for writing in.

I wish you had uploaded a photo of your compressor, as I cannot find an image of it online to have a look.

Anyway, if you have to push the air compressor reset button, and that reset is connected to or on your electric motor, then it sounds as though the motor is going off on thermal overload. Does the motor get really hot?

You are right, a pressure switch is cheaper than changing the motor. You might want to replace that just in case. The worst case scenario is, if that doesn’t solve the problem, you’ll have a spare pressure switch for some time else.

Under the lid of your pressure switch, you should see a wiring diagram. Use that, and, do what I do… take a digital photo of the pressure switch before your remove a wire so you know which goes where when you replace it.

Make sure you disconnect the power and dump the air first, of course!

Craftsman 5 HP Compressor Trips Breaker on Startup

Question

My craftsman 5hp 20gallon compressor trips my breaker at start-up? Craftsman 5hp 20gallon compressor tries to start up but trips my 15amp breaker.

It will run a second or two before doing it. The unloader valve seems to be working, it moves in and out while trying to start, turning the regulator to low or max makes no difference, the check valve works in and out, and the motor fan turns the piston without any snags, what could be the problem?

Response

Is this a new condition? What has changed in the power supply? My first check would be to see what else is pulling power from the same supply circuit.

When you say that it runs for a second or two, does it actually pump air, or is the motor trying to start for a second or two, and then the breaker pops? If this is the case, then I would consider your capacitor suspect. It may not be supplying enough boost power to get your motor going, the motor pulls too many amps for the circuit without the capacitor boost, and the compressor breaker pops.

If neither of these is the cause send me a note as a comment on this thread telling me what you have done, and I’ll respond further.

If you haven’t looked at the page about BLOWS BREAKER OR FUSES from the troubleshooting page, I’d suggest that’s a good read.

Question

Please post a follow-up as this motor is nearly $300. I’d like to get this thing running myself without spending anywhere near that. I have narrowed it down to the motor and want to know if you or anyone else has solved and fixed this problem, and also how much time and money were spent doing so.

Response

You may wish to check the circuit breaker. They also get weak.

Campbell Hausfeld Compressor Runs Slowly then Trips Breaker

Question

I have a Campbell Hausfeld (6 hp 30 gallons) air compressor model WL611201AJ that is about 14 years old.

When I turn it on the motor runs slowly and then trips the breaker.

It doesn’t matter if there is pressure or not in the tank. I have it plugged directly into a 120v 15 amp outlet. It has worked fine at the current location for some time. I recently switched outlets and the same result. If I use the WL373001SJ Campbell Hausfeld Air Compressor Pump/Motor Kit replacement.

Will this fix the issue?

Thank you.

Response

Vincent, if this was my Campbell Hausfeld air compressor, from the symptoms you describe, I would be checking out the start capacitor.

That would be quite a bit lower cost fix than the kit you refer to.

If you prefer, however, I do believe that the kit would resolve your compressor problem.

Response

I agree with Bill, start capacitor would be where to start on this one.

Question

Can someone help me identify where the start capacitor is located on this model?

Response

Vincent, the two “humps” sitting on the motor are the capacitors. One is the start cap, the other is the run cap.

Question

I believe I have identified the start capacitor in this compressor. I have checked it according to the checking capacitors page listed here and it is bad. as well as split and leaking. The numbers listed are Aerovox c103237300423. 233-280mfd. 220vac. 60hz. The 220vac is confusing me. The compressor has run from a 110v 20 amp circuit for years. Anyhow, can someone tell me the best place to locate the correct capacitor?

Response

I suspect the rating indicates that it’s good up to 220 VAC.

As to getting one, why not start with Aerovox themselves?

Devilbiss Air Compressor PRFBC 5525 VP Blows Breaker

Question

I picked up a used Devilbiss PRFBC5525vp that likes to pop breakers. It starts up and runs for 2 seconds then crashes.

I replaced the capacitor in the motor hub (150 MF rather than 135) and had the other capacitor checked at a shop. It was ok.

The motor turns by hand quite freely and even took the main outlet off to make sure there was air being pushed. What am I missing or is it that second capacitor?

_ Cary _

Response

Hi there Cary…

I tried to find the specs and a photo of your Devilbiss PRFBC5525vp air compressor online with no luck, so I’m kind of shooting in the dark here.

Often, but not always, the compressor symptoms you describe are related to the power supply.

Good that you checked the caps and replaced one. See the page under troubleshooting for how to check the other one if you wish.

As a comment here, tell me about how you are getting power to your air compressor, and the amperage of the breaker your air compressor is plugged into.

Question

Thanks, Bill. Yes. I couldn’t find a picture either. Everything else on the unit works with no leaks. Pressure on/off trips normally. (connected to another working air pump). The power is straight off the panel. I tried 15 amps first then 20. Same result. It doesn’t look like it could be wired for 220 either but that shouldn’t matter I think.

Response

A 20 amp is good for a few HP. What’s the HP of your compressor?

Pull the line from the pump to the tank. Start the compressor. Still the same problem?

And you can always upload a photo now if you wish. It will help all help you!

Question

The motor is 5 HP. My other 5 HP compressors needed 20 amps but had run well at 15. This one blows the 20 amp breaker.

I tried removing the tube and it didn’t change the situation. There was airflow from the cylinder outlet so the head itself should be good.

Response

I am not an electrician, but when I search for the recommended breaker for a 5 HP motor, I keep coming up with 40 amps.

Question

Uh.. yeah. Sorry. I took the motor off and checked the plate. AO Smith model K56A75B23, 120 V, 15.0 A, 60 Hz, Single phase, 3450 rpm, CW.

It may be possible to just replace the motor but it would be a shame if I couldn’t just fix it.

Response

There is a check valve to hold the compressed air in the tank while the unloader valve drains the compressed air off the head of the pump. This happens each time the compressor shuts off. If the compressor is not draining off the compressed air from the pump it will try to start against a load and blow your breaker.

Also, if the check valve is leaking, you would be starting against the tank pressure and blowing the compressor breaker. Both are cheap parts to replace.

Question

Hi Bill, I have the same problem as Cary. In your last post, you said to remove the line from the motor to the tank. I did that and it ran like a scared cat. Can you diagnose this for me, please?

Response

Did you check the capacitors?

By removing the line you removed the load from the pump, and it can run easily, even with weak caps.

Or, check the tank check valve to see if it’s blocked, first.

919-167310 at Initial Start-Up Blows Breaker

30 gal. Craftsman 919.167310. No air in the tank.

Tried different amp sockets of 20 and 30 amps. Does the same thing.

Tried replacing capacitors of the same type (30 mf- 370v). No joy. The compressor does exact same thing with NO capacitor wired in. Turns fine by hand.

Response

Sounds like the centrifugal switch is not closing properly when the motor is stopped.

This happens to explain no difference when there is no capacitor…

Hope that’s it, as otherwise your start winding may be kaput.

Question

I took off the backplate to get at the points. They were together when stopped. I filled them clean and restarted the motor. They pulsed when I attempted to start the motor but stayed together. Points did not appear to be “open”.

It seems Sears does not sell the centrifugal switch separately nor does it carry this motor any longer.

Response

Bummer.

If we’re certain it only has one capacitor, then it seems the motor is bad – for whatever reason.

If you can get it to a motor shop to bench test it, that would be good, and they’ll probably have a similar motor in stock if you need one.

If that’s not practical, I’m afraid it’s time to go shopping for either a motor or a new compressor.

Response

All may not be lost. It appears as though there are some commonalities among centrifugal switches.

If you Google “buy a centrifugal switch for compressor motor” as I just did, you will find a) lots of info and b) sources to obtain them.

Question

There is a 136-163 mfd starter cap within the backplate made by Mallory. 220 vac. How close do I need to come to this output for a replacement? Can I go larger if the unit fits within the motor?

Response

The page on this site that talks about sourcing capacitors says “if the new capacitor has the same voltage range, the same microfarad range, and you can attach it to the existing mounting of the motor capacitor on your compressor, you can use it. Even if it’s a different shape, a different color, longer or shorter or bigger around, as long as the voltage and microfarad ratings are the same, it is a suitable capacitor for your compressor motor.”

Response

OK, I had thought this might be a one-cap thing. Since it has two, that means you replaced the run cap, given the values we now know.

136-163 mfd 220V caps are readily available. If you have one on hand that’s larger, with at least a 220v rating, that may well be ok since it’s only in the circuit for a brief time during start-up.

What cap (mfd and v) were you thinking of trying?

Question

I searched the net and found a company that sells this exact capacitor for the A.O. Smith motor on this compressor.

I will let you know if this works.

Compressor Shuts Off Before Reaching Pressure

Question

The compressor shuts off without reaching full operating pressure (circuit breaker trips)

Response

Make sure the power supply to your Harbor Freight air compressor is “clean”. By that, I mean no extension cord is used, and no other appliances pulling power from the same circuit the air compressor is on.

If the problem persists when you have clean power, then it might be a failing pressure switch allowing a short and popping breaker, it could be the motor is laboring and pulling too many amps, or it could be the start/run capacitor isn’t working right… many things.

What pressure does it reach before the compressor breaker pops, and is the breaker popping at the same pressure on the compressor every time?

Post a response here please, if you wish, so I can follow the thread.

Question

Pressing the reset button after the circuit breaker trips allows the compressor to reach full pressure. it runs for about one minute before it cuts off each time.

Response

Hoping that you have clean power, as noted, at what pressure does the breaker trip? Same pressure each time? If it’s happening at differing pressure points, then it may not the pressure switch.

Response

OMG fellas. don’t make a huge project out of this. by-pass the reset switch. That’s all that’s wrong. Just cut the wires, twist them together and spin a yellow wire nut on there.

Response

That’s one line of thought. On the other hand, if the reset is tripping due to overheating of the motor, then by following your advice you will, for sure, overheat the motor. Not good if you want your motor to last.

Question

Hi, what’s up? I have had my compressor for about 2 yrs. The same one you have. From day one I have to hit the reset 10-16 times before it will stay running. First I used an extension cord so I did away with that. Now it is directly into an outlet. It still does it and I have tried different outlets with the same results. I do not use that much!

It is so loud it hurts your ears. Next, it is full of air at 150 PSI. Shuts off and go to check the air in my tire and I put in 5lbs.and the compressor kicked back on and it keeps doing that so anything I am working on and off on and off.

Campbell Hausfeld Compressor Trips Breaker

Question

I have a 10-year-old Campbell Hausfeld 5HP 120v on a dedicated ckt. Has run flawlessly since new. I occasionally leave it turned on when I’m using it a lot, so I don’t have to wait for it to pump up. Now this Campbell Hausfeld compressor trips breaker.

Went out yesterday to pump up a tire and had no air pressure and the compressor breaker was tripped.

Reset the compressor breaker, it ran for about 4 sec slowly, then tripped the breaker again…repeatedly.

Removed drive belt and started again…motor ran at normal speed, but then tripped the breaker after 4 sec with no load. What do you think?

Response

Dave, that’s a good one.

Good that you pulled the belt to check, as, for me, that pretty much identifies the motor circuit as the source of the problem.

See this page on this site about checking your air compressor capacitors, as that would be the first thing I would check if my compressor was exhibiting your symptoms.

Question

It turns out that I had a bad run capacitor in the motor. It was visibly swollen and shorted.

$27.50 for a new cap from my local motor shop and I’m back in business.

Thanks for all the suggestions.

I Have an Old 1 HP 3 Gallon Campbell Hausfeld Air Compressor Turns On and Off After Tank Fills Up

Question

But after using it for a while, the pressure goes down and it won’t turn back on and trips the main fuse after it makes a starting sound, then a sound of air escaping coming from below the switch.

I have already replaced the broken fan and the rusted valve plate(kit) (pls. note..it’s not the check valve)

Response

Edwin, the sound of air rushing from the pressure switch is, I suspect, that of the UNLOADER VALVE working.

The unloader valve opens when the pressure switch trips the power off, shutting off the compressor motor.

When the pressure switch trips on at a low-pressure cut-in, that closes the pressure switch, while the air compressor is running.

That your compressor dumps air again after trying to start suggests to me that it is your pressure switch that is failing, and when trying to start the air compressor, shorts the power, blows the breaker, and trips the pressure switch back off. I think!

If the pressure in the tank is below cut-in, the compressor should start. When the tank pressure reaches cut out, the compressor should start. Both of these actions are initiated by the pressure switch reacting to the changing pressure in the tank.

If the pressure switch trips off before the tank pressure reaches cut out, it is probably the pressure switch that’s at fault, and it’s shorting the circuit.

Question

Bill, I have really come upon a mystery.

I have disconnected the motor from the compressor and direct-wired it to an outlet wired directly off the outside power supply.

What I am saying is this, the only wire between the motor and the power is the cord about three feet long, a temporary outlet, and a compressor breaker.

I plug it in and it blows the compressor breaker! I took the motor to an electric shop and the fellow there replaced the run capacitor it runs on his power supply.

I took it back home it blows the compressor breaker immediately even with the new capacitor. Pretty frustrated now since the electric fellow can run without a problem. OK, so I am really scratching my head now?

Response

If it runs at the repair shop, suggesting that the capacitor and the motor are fine, then the only variable is your power supply. You may have only a short cord to the motor, but what else is on the same circuit that is pulling power as your compressor motor is trying to run?

Response

A slow motor at 1/2 speed indicates the wrong motor voltage. A dual Voltage Motor may be wired for high voltage 220 volts or maybe 3 phase motor not a single phase. Check the motor plate for correct voltage and wiring. It is common for factories to ship motors wired to a higher voltage. A 3-phase compressor tripping breaker is common.

You must set it to the voltage being used. The motor plate or spec sheet will state min. fusing required and maximum fuse allowed

Question

Thanks, Bill, however that didn’t work either. It will run slower than usual like a half-power then the motor trips breaker after 5 seconds. It appears as though it simply can’t pull enough power but I am certain it has plenty for its rating. Thank you. What can I look at next?

Central Pneumatic Model 61454 Overload – My 61454 Keeps Tripping the Overload Protector

Question

I have a 5-year-old central pneumatic 21gal compressor model 61454 that keeps tripping the overload protector.

When I turn the unit on it runs for ~15 seconds and then trips the overload.

If you hit the reset button the unit will run for ~5 seconds then trip the overload again, which you can keep repeating.

If you let it sit for 1 minute you can reset the unit will run for ~15 seconds again.

The unit is in great shape and hasn’t been used that much.

The unit is on its own circuit which it has been on for the last 5 years.

After reading some different complaints about the unit I replaced the oil with fresh synthetic compressor oil which did nothing.

Seeing that people complain about the capacitors going bad on them I checked mine. The unit has 1 capacitor, it has a few minor dents on it, but it appears to be functional (builds resistance when hooked to a multi-meter).

Any thoughts on what the problem could be?

Response

A couple of thoughts –

Is the filter reasonably clean?

Otherwise, sounds like a motor failure, or the overload protector is broken/weak.

Ideally, check the current with a clamp-on meter or something like a “kill-a-watt” meter. Should be 13-14 Amps. If that’s the case, and it blows, then the protector is bad.

If it’s much over 15A, then you may have a motor problem, and hope it’s the cap. When they lose capacitance, that can cause this, even though it’s not “clearly bad” as in open or shorted.

Let us know how you make out, please.

Good luck.

Question

Thanks for the suggestions, Doug.

I checked the filter and it looks clean.

I then picked up a clamp meter and tested the unit. The number fluctuates a lot…but it seems to be running about ~16.6 amps on the hot lead, ~15 on the neutral, and ~1.6 on the ground…then pops the overload…

So it seems like you said, it is a motor problem.

Is there another way to test the capacitor other than measuring the resistance as I did? If it is just the capacitor any suggestions on where I could purchase one for the unit…some people online say it’s a hard one to find and that harbor freight is no help… I even saw people talking about combining 2 smaller capacitors to get the correct capacitance of the one on the unit.

Response

Any capacitor that has the same microfarad rating ( µF ), and the same voltage, should work, as long as you can get it to fit the footprint.

Response

Chris:

ALL of your currency from the hot side should be going thru the neutral, and the ground should be zero.

\An electrically leaky cap might cause that.

If you have a GFCI breaker on it, it should trip, but I’m guessing you don’t.

Some multi-meters have a capacitance range, but they may not be able to accurately read large caps, so if you decide to buy, check that it goes high enough. Google “capacitance meter” and you’ll find a few, along with a good explanation of how it works from Fluke.t

The manual doesn’t seem to have the value(s) of the cap. What is it? Maybe I can help with that.

And yes, unfortunately, HFT is not very good about spares, like most sellers. Sadly, it’s just not economical to do so.

Question

Thanks again Doug and Bill,

You are correct about the unit not being on a GFCI breaker…should it be?… Turns out that the clamp meter I picked up can do capacitance. I tried testing the capacitor, but it overloads the meter….I checked manually for the meter and it can’t measure past 100uF or the capacitor is bad.

After seeing that I can’t measure the capacitor with my meter I tried testing it again with resistance….this time I get no resistance at all…Could the capacitor have fully failed when I played with the unit trying to measure the amps?

The capacitor specks are as follows

Huizhong CBB65A

130uF +/- 5% SH

250VAC 50/60Hz

40/85/21 CP

Internally Protected

10000AFC PB1300

On Amazon, I see capacitors with

108-103uF 250V

130-156uF 250V

Would either of these work…or do I need to be more exact with the 130?

Thanks again for your help

Response

I mentioned the GFCI because if there were one, it’s failed. Not having one is OK, but a while back the NEC started requiring them on all 120V circuits, even lights. They used to require them only on circuits subject to dampness, like laundry, kitchen, and bathrooms.

Anyway, capacitor:

Given the value, (130mfd or 130μ), and voltage, it would be a start cap. That being the case, it’s not critical, so I’d go with the cheaper one, as long as 130μ is in its range.

I suspect that the cap that’s failed was available cheap, and the +/-5% is overkill. If it were a run cap, then it’s more critical because it’s in the circuit all the time.

You might consider getting one of each, as it’s possible that the reason this one failed is that the centrifugal switch in the motor also failed (not opening), which will cause the new cap to fail, sooner or later.

HTH, and good luck.

Question

Doug,

Sorry, it took a while to respond.

I ordered a new 108-130uF starting capacitor and swapped out the old one. Unfortunately, my compressor is still having the same issue of running for 15 seconds and then tripping the overload. The unit is still reading in the high 16 amps and I am still getting an amperage read on the ground with the new capacitor. I assume that probably means the motor is shot and I should consider replacing it or the whole unit.

Response

If your compressor starts up and then shortly trips the built-in compressor breaker, it has nothing to do with the electrical system.

Simply look on the head of the motor, and you will see a screw-in valve with a nipple on it. seems to be a compression release to prevent hydro locking. Unscrew it and turn on the compressor. it will leak out from here. however, if it keeps running without shutting down, there is your problem. I have the same model and as of this day cannot seem to find a replacement part for it. just adding my 2 cents in. thanks.

Response

I beg to differ.

It appears you refer to part 3 in the parts list.

It is called a “start valve”.

That’s actually an engineered leak to relieve pressure on the pump head when it stops. It is an inefficient substitute for an unloader.

In case you are not referring to item 3, say which it is.

Response

Two things here, I have worked on industrial air compressors for 12 years. If it bogs down and trips the compressor breaker it’s more than likely the check valve on the tank, not the start valve. Or your capacitor is going out and bogging the motor down. The pressure switch relieves the head pressure on shutdown, not the start valve.

A number of existing reader circuit breaker problems and responses for varying compressor brands and models are also accessible on this site:

- DeVilbiss Air Compressor Trips Breaker

- Husky Air Compressor Keeps Tripping Breaker

- Craftsman Air Compressor Keeps Tripping Breaker

- Porter Cable Air Compressor Keeps Tripping Breaker

- Ridgid Air Compressor Keeps Tripping Breaker

- Ingersoll Rand Air Compressor Keeps Tripping Breaker

- Campbell Hausfeld Compressor Trips Breaker

- Sears Air Compressor Keeps Tripping Breaker

If you have any questions regarding an air compressor circuit breaker tripping, please leave a comment below, with a photo if applicable, so that someone can help you!