If you own an air compressor it’s likely that at some point you will need to replace the air hose fittings, so, you must be aware of all the different air compressor hose fittings types and sizes to ensure you know what to buy! This article will provide you with all the relevant information on air hose fittings, including the types, their measurements, and a buying guide.

Table of Contents

- Air Compressor Couplers and Fittings

- Air Compressor Fittings Types

- How Are Air Hose Fittings Measured?

- Types of Air Compressor Fittings Buying Guide

- FAQs (Frequently Asked Questions)

Air Compressor Couplers and Fittings

If you’ve ever manually blown up an inflatable beach ball or mattress then you will be aware of pneumatic tool values. They save you so much time and effort! Can you imagine trying to put enough air into your tires manually?? Impossible right?

This is where air hose fittings come in and are so important. They attach to the end of your air hose and connect to your compressor or tank to allow you to connect pneumatic tools to your system. Anytime you switch on your compressor to conduct any form of work, you are heavily relying on these ever-so-important fittings.

Benefits of Air Hose Fittings Types

Air hose fittings are key to making the most out of your air compressor. Without them, you won’t be able to use your compressor at all! Fittings are necessary to allow the connection of all parts of the compressor, directing air into the hose so that you get the desired pressure at the end of your line.

Having a supply of air hose fittings available on hand can help prepare you for anything. These small fittings are responsible for the connection of specialized tools to air compressor systems, therefore, allowing you to diversify your tool range.

Getting controlled air pressure will provide you with virtually endless applications. From being able to run a nail gun to painting your car, restoring your wheels, or even running advanced power tools, having the right fittings opens up a world of possibilities. Air hose fittings, therefore, enable you to work on bigger projects.

Having the right fittings on your air compressor can help provide a better seal, which means that less air is being wasted and energy consumed to do the same amount of work. This not only helps the environment but also helps keep your costs down. You could view the investment in air hose fittings as an investment in efficiency.

One thing you should ensure is keeping backups of each fitting on hand. Treat them like screws, they’re easily misplaced or damaged and so keeping some spare on hand will ensure you are able to see your work through.

Air Compressor Fittings Types

The two air hose connector types that are essential for the connection of pneumatic tools to hoses are compressed air plugs and couplers. Let’s take a look at both in greater detail!

Compressed Air Plug

For us, DIY folks, and for a lot of industrial plants that use compressed air, one of the most common fittings we will use is the compressed air connector, otherwise known as a compressed air plug.

The purpose of compressed airline plugs is to mate with a matching coupler on an air supply line and to facilitate secure connections between the two. This allows compressed air to flow through to the air tools or air-using components in the workshop or plant.

Since airline connectors are inexpensive devices, each costing a dollar or two at most, using them abundantly for quick connection of your air tools is the way to go. Thread a connector into the supply port of every air tool you’ve got, thereby making them ready for immediate use.

By having a connector installed in every air tool in the shop, changing your supply air hose from one air tool to another is simple and fast. Unplug one tool air connector from the airline coupler, and insert that of another air tool into the same coupler on the same airline and you are back in business.

Plugs deal with flow sizes and are rated accordingly. The most common is a quarter-inch setup, though 1/2″ and 3/8″ are also very popular. This metric or rating, tells you how much air volume the plug can manage. There are typically two main types of compressed air plugs: automotive and industrial.

Automotive types are T-style and Type and will typically be color-coded blue, while industrial types are M-style and Type-D and will typically be colored red.

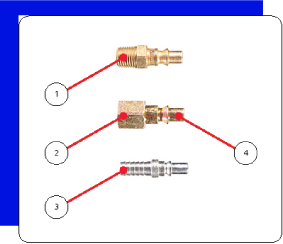

A typical connector is shown in the photo above. On this connector, an NPT male thread is on the left end. On the right end of this connector is the part of the connector that plugs into the matching coupler.

This is a manufacturer-specific connector shape, meaning that this connector shape must correspond to, or match the design of, the coupler into which it is inserted.

Item 1 in the photo is a connector with a male NPT thread. After coating the male threads with thread sealant, this connector can be threaded into the mating female NPT threaded hole in an air tool or any device needing an air supply.

The male NPT threaded connector is the most popular method of connecting an air tool to a compressed air supply. Have an abundant supply of these on hand to quickly thread one into any additional tools acquired.

Item 2 shows the same connector with a female NPT thread, allowing this connector to be turned onto a male thread. Item 3, still talking about the photo of the connectors above, is the same connector again, but this one comes with a barbed connector, used by inserting the barb into the I.D. of an air hose.

A gear clamp is then placed on the outside of the hose which has been pushed up and over the barb, with the barb inserted fully inside the hose. When tightened, the gear clamp will exert force around the entire outside of the hose, compressing the hose wall against the barbs, and making a secure seal.

All three of the connector formats above are industry standards. Two have standard NPT threads. Item 3 in the photo has an industry-standard barb. The barbed end is sized by its O.D. measurement. Therefore, a 1/2″ barb would fit into a 1/2″ I.D. hose.

For me, just a few of items 2 and 3 are enough for my air tool kit, as I use the male format (item 1) most frequently. The methods of installing a connector into an air tool or onto an airline are common and are shared by many manufacturers of connectors.

Compressed Air Plug Shape

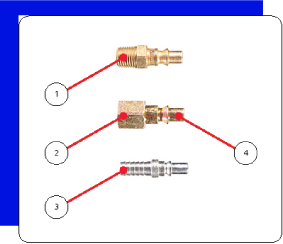

Item 4 in the photo below is an issue to be considered.

The right side shape and size of the connector shown in the photo above could be proprietary. This means that its design may be unique to a specific manufacturer’s brand. Or, it could be built to emulate another company’s coupler design or to meet an industry standard.

This is the part of the connector that has to match the size and shape of the inside of the mating coupler. If it does not, you may not be able to insert the connector into the coupler at all. Or, if you can insert the connector and it is the wrong design, at best the connection will leak, and at worst, the connector could blow off from the coupler, usually at the worst possible time.

There are many different styles and sizes of connector configurations available in North America, and around the world, and, as noted, not all are interchangeable. As a result, you have a decision to make when it comes to selecting connectors, and mating couplers.

Your compressor may have come bundled with a fitting kit of some sort, similar to the one shown below.

This kit has the coupler on the left, a connector with a female NPT thread, the same connector with a male NPT thread, and a male-to-male adapter.

You could simply use the kit that came with your compressor, but no others, and be able to use your compressor and air tools but perhaps with a bit of difficulty, as you may not have enough connectors to go around to all the air using devices you may have.

If a coupler/connector kit came with your compressor, ask the store clerk to identify their store brands that match those in the coupler/connector kit. Consider buying a number of couplers and lots of connectors of the same brand/configuration at that time.

If it were me getting my new compressor, I would pick up at least a dozen connectors and half a dozen complementary couplers so that I had extras when I needed them.

And yes, I expect you will need them. We compressor users like our air tools and as mentioned, it is a whole lot faster to change tools when you have a connector already threaded into the air tool intact port and one or two extra, ready to thread into the next air-using toy you acquire!

Compressed Air Couplers

Compressed air couplers are part of the compressed air line connection tag team, the couplers, and connectors. This typically female fitting type attaches directly to the airline or compressor. Made from the same materials as their male counterparts, couplers are the “receiving fitting” so to speak. The coupler connects to the hose while the plug will attach to the pneumatic tools its powering.

If you have threaded an airline connector into the supply port of each of your air tools, which is what you want to do to be able to connect a compressed air supply to each quickly and as needed, those connectors allow the quick connection of any air tool (or any other air component, for that matter) to a mating coupler on an air hose.

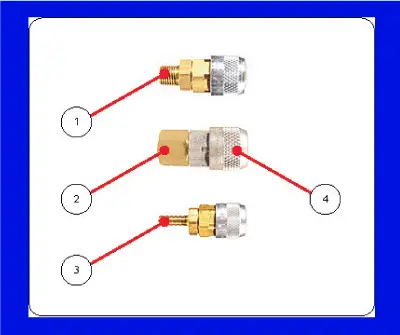

In the photo below all of the couplers are from the same manufacturer though each has a different method of being connected to an air hose or air appliance.

Compressed Air Couplers Shape

Item 1 shows an NPT thread, item 2 is a female NPT thread and item 3 is a barbed fitting. Item 4 in the photo above is the critical concern when acquiring couplers.

When buying couplers you need to make sure that the internal configuration of the new coupler (the inside of item 4 shown in the image) matches the external shape of the mating connector.

In order for the coupler to connect properly to the connector, it must be a compatible design. If not, you may not be able to insert your connector into the coupler at all, or if you can, it is possible that the two will blow off unexpectedly.

Though there are some industry standards for couplers and connectors it is an unfortunate truth for compressed air users that sometimes a coupler from one company won’t fit the connector from another company, and the reverse is true as well.

Connecting a Plug & Coupler

There is often a lot of grunting and hissing occurring when one tries to insert a connector into a coupler.

The grunting is from the person who is trying to hold the coupler, slide the knurled ring back towards the hose with the same hand, and at the same time try to insert the connector into the coupler with the other hand.

Escaping compressed air provides the hissing, while we grunt, trying to get the darned things to connect. It seems that we never have enough hands.

In the photo above, item 1 is the coupler. One way to connect the two is to simply push the connector into the coupler. A good quality coupler may simply snap back and into place, holding the connector tightly.

Of though it is necessary to hold the coupler and hose in one hand, and pull back on the sleeve (the knurled part) of the coupler with the fingers of that same hand.

At the same time, you push the connector (item 2) into the coupler with the other hand until it bottoms out.

When the connector is inserted/seated all the way, you release the knurled ring on the coupler (not the coupler itself, just the ring) which is spring-loaded, and it snaps forward. You then, carefully, ease off on holding the connector just a bit, until you are sure that it has been captured by the coupler.

Don’t let go of either component completely until you are sure they are mated. Sometimes they pop apart, with a lot of hissing. Been there and done that!

As a home workshop coupler user, expect that the low-cost, big-box store couplers and connectors are sometimes hard to connect, may too easily disconnect, and they leak, particularly if you “sideload” the coupler/connector at all.

It’s very easy to do. If you are using an air drill or grinder or air nailer or any air tool that has its connector plugged into a coupler on the air hose, it is almost impossible not to impart a sideways motion to the coupler-connector connection as you are using the tool. In so doing, you are side-loading that connection.

When that occurs, the coupler/connector can leak, particularly if it is a low-cost set. You will hear the connection hissing, and in so doing, bleeding compressed air, the energy that was used to compress the air, and the money you spent on that energy, to the atmosphere!

How Are Air Hose Fittings Measured?

Air hose couplings and other connections that are consistently used for air compressors, typically follow a system known as the NPT fitting standard. NPT, National Thread Tapered is a US standard for tapered threads used for a variety of fittings and pipes.

There are also Metric Fittings that look the same as NPT fittings, and a 1/4″ NPT fitting will have a similar diameter to a 1/4″ Metric fitting, but they are not interchangeable. Metric fittings have key differences in the tip-to-tip distance of the thread. As a result, metric thread sizes are incompatible with their NPT same-sized counterparts.

Let’s not ignore British Standard Pipe (BSP) fittings, they’re a family of standard screw thread types that are used internationally for interconnecting and sealing pipe ends by connecting female and male threads. These threads are measured and based on the inside of the hose fitting.

Back to the more widely used, NPT, their fitting standards allow you to select equipment that is measured in standard air fitting types, therefore you already know that it will be compatible with other fittings and also any preinstalled couplings that came with your air compressor when you purchased it.

NPT, also referred to as American standard pipe refers to the size of the thread on any connector as well as the size of the connector. The thread size is certainly important, because any non-standard fittings may not provide an adequate seal, and allow air to escape from your air hoses and connectors. This, of course, will significantly reduce the efficiency of your system, the airflow, and the pressure that the compressor is capable of delivering to your pneumatic tools.

While it is fairly easy to gain an understanding of the air compressor fittings, it can still be of benefit to understand the NPT fitting chart and its relationship with pipes and all types of connectors. NPT charts are usually in inches and include the outside diameter of the pipe and the threads per inch. Typically manufacturers will advertise their NPT fittings to conform to these figures at a very high level of accuracy.

Air Hose Fitting Sizes

| Pipe Size (Inches) | Threads per Inch | Outside Pipe Diameter (Inches) |

|---|---|---|

| 1/8″ | 27 | 0.405 |

| 1/4″ | 18 | 0.540 |

| 3/8″ | 18 | 0.675 |

| 1/2″ | 14 | 0.840 |

| 3/4″ | 14 | 1.050 |

| 1″ | 11.5 | 1.315 |

This NPT fittings chart above shows the most commonly found and used NPT thread sizes and their respective threads per inch count, along with the measurement of the outside diameter of the pipe.

Many air hoses will typically come fitted already so you can start connecting your air compressor to your tools, with any additional couplers being the same sizes as the readily installed fitting. If you, however, are unsure what size fitting you need, here is a simple methodology for working out the circumference of your hose:

- Take your air hose and a length of string, and wrap the string around the hose, making sure you keep the string running around the diameter straight and true

- Mark the string across on both ends and lay it out next to a tape measure

- Read the length of the string from mark to mark. This will give you the circumference of the hose

- Take this length and divide it by PI (3.1416 roughly) and this will give you the diameter of the hose

Numerous types of air fittings are available but most tools tend to use one of just a few types of connectors. Most of these tools use a 1/8″ or 1/4″ connector, but of course, the size may not always conform to these standards. The best way to know the size of your connector is to look the part model up online

A method for measuring the port opening size on a tool is to simply measure the diameter at the opening, and measure right across the center of the port. When you have an accurate measurement, you will know the pipe size and be able to find a suitable connector.

I’ve provided a useful YouTube demonstration below.

Types of Air Compressor Fittings Buying Guide

When you select new couplers for your home workshop, it is convenient and easy to buy kits with matching couplers and connectors.

What I normally do is select one brand from my local outlet, buy lots of couplers and mating connectors, and then discard all of the others that do not connect, or are suspect. Do yourself a favor and only keep compatible brands of couplers and connectors in your tool crib or toolbox.

For the industrial user, you can purchase quality couplers and connectors from your industrial compressor distributor or industrial supply house. The same rule applies. Only keep compatible brands in stock. Otherwise, you’ll always grab the wrong one when working on a new application, necessitating a trip back to the tool crib and wasted time.

These fittings are a very important factor in ensuring the control of airflow and pressure. A small leak within them can lead to very large issues (since they’re closer to the pneumatic source). You must ensure that the sizing and machining quality will provide a reliable seal for the best results. You’ll likely need more plugs than couplers, though the latter is more prone to wear and tear.

If you buy good quality couplers and connectors, they are more reliable, easier to insert and remove, and are generally able to better resist leaking, important issue if you are using compressed air regularly and often.

Some couplers even offer additional functions such as an integral relief valve to vent trapped compressed air safely before disconnecting the coupler from the connector, a considerable improvement over popping the two apart when there is air trapped in the line.

For most DIY users, however (including myself) the low cost of our couplers and connectors offset the annoyance of periodic leaks and connection foibles, though I sure do curse the darn things from time to time.

Air Compressor Fittings Types Buying Considerations

First of all, you must consider the design and structure of the fitting. The craftsmanship quality that goes into the machining of air compressor fittings speaks for itself, and whether it will work properly or not. Not only must the material be tough enough to withstand the high pressures within the pressurized system, but it also must have an air-tight seal. Even the slightest flaw can be enough to ruin your air pressure. Seek strong metals manufactured by reputable brands with effective designs.

Next, you will want to consider the connection type, push-to-connect are always favorable choices due to their ease, but they may not provide you with your desirable air-tight seal. All quick disconnect couplers are the fastest, easiest means of joining air tools to hoses. If you want precision, you must think about how the fitting actually plugs or couples and if it can handle the pressure of your system once you’ve set it up.

The compatibility of the air hose fitting is ever so important, and it really depends on your task at hand. For example, if you’re working with pneumatic tools or looking to airbrush your car with an HVLP system, you’ll need different types of fittings. The following can be used as a guide:

Air Fittings Types

- Type B: A-style/green/ARO

- Type C: T-style/blue/automotive

- Type D: M-style/red/industrial

- V-Style: HVLP uses

Color coding can typically be the quickest way to know what fitting you need, however, this is not always the case: not every manufacturer will color-code their fittings. Color coding is worth keeping an eye out for as it can save your time and provide you with convenience.

Another thing to keep a lookout for is guarded sleeves, these help reduce the strain on sleeves and therefore postpone the wear and tear. This way, when you move the hose around it won’t put as much pressure on this part, going a long way toward durability.

Air Hose Fittings Types Available Online

I have picked out an example of a coupler and plug fitting which are both readily available on Amazon below, both manufactured by Milton (a company I would recommend looking out for).

- Milton s-765 HI-Flo V-Style A,M,V 1/4 MNPT Brass Body

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

- Basic flow size of 74 standard cubic feet per minute

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

I have also picked out a few Amazon kit listings that could be perfect for you. In some cases, it may be worth purchasing a full coupler and plug kit. This will provide you with enough pieces and spares in case of any damage. The first is this 16-piece brass quick connector set. It has 8 x male plugs, 4 x female plugs, 2 x male couplers, and 2 x female couplers.

- 【PREMIUM MATERIALS】: Construction of solid brass for high corrosion resistance and a longer using life

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Another option is this 14-piece 1/4″ NPT I/M type quick connect kit made from stainless steel which appears to be an Amazon choice.

- I/M type air fittings with 1/4NPT threads.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

Finally, this 14-piece WYNNsky air hose fitting types set, which is color-coded, boasts terrific reviews, and is also available in various different-sized sets.

- Product Using: Universal coupler accept the three most popular interchange, I/M, ARO and T type, which is perfect for shops where multiple plugs are used.

Prices pulled from the Amazon Product Advertising API on:

Product prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.

FAQs (Frequently Asked Questions)

First of all, we have couplers and plugs. Two separate air fittings that when combined allow you to connect air hoses to pneumatic tools. After this, we have four key types of fittings in which couplers and plugs are available. These are:

Type B: A-style/green/ARO

Type C: T-style/blue/automotive

Type D: M-style/red/industrial

V-Style: HVLP uses

The most common size air fitting is 1/4″ and this is true with both 1/4″ and 3/8″ hoses. Even 3/8″ hoses normally come with a 1/4″ end on it and so they use 1/4″ air fittings.

Air hose fittings are typically in the region of 1/8″, 1/4″, 3/8″, 1/2″ or 3/4″ pipe thread, with 1/4″ being the most commonly used size.

Additional Reading:

- Using Aluminum Air Pipe For Compressed Air

- Copper Pipe For Compressed Air

- Galvanized vs Black Pipe

- Using ABS Pipe For Compressed Air

- Using Nylon Tubing For Compressed Air

- PVC Air Lines

- Using Pex Pipe for Compressed Air Lines

- Best Compressed Air Pipeline Materials

- Steel vs Brass Air Fittings

- Industrial vs Automotive Air Fittings

- Compressed Air Metric Fittings

- Compressed Air Fittings

- Air Compressor Hose

- Using Pex-Al-Pex Compressed Air

- Pex A vs Pex B Pipe & Fittings

- PEX Fitting Types

- How to Plumb an Air Compressor Setup in Garage

If you have any questions regarding air hose fittings types, please leave a comment below, with a photo if applicable, so that someone can help you!