What is an air compressor pressure switch and what does a pressure switch for an air compressor do? Importantly, how does an air compressor pressure switch work? Thinking of buying a new pressure switch? More importantly, how do we fix problems with compressor pressure switches – or decide whether your compressor needs a new pressure switch!?

All of your questions about air compressor pressure switches are answered AND more in this very article. I’ll even give you some guidance on buying a new pressure switch for your air compressor.

Table of Contents

- Existing Questions & Solutions to Pressure Switch Issues

- What is an Air Compressor Pressure Switch & How Does an Air Compressor Pressure Switch Work?

- Troubleshooting an Air Compressor Pressure Switch

- Buying an Air Compressor Pressure Switch

- A brief recap of buying a new pressure switch for your compressor

- I can’t find the compressor pressure switch?

- Still have Compressor Pressure Switch Issues?

- FAQs (Frequently Asked Questions)

- Additional Troubleshooting Pages

Existing Questions & Solutions to Pressure Switch Issues

We’ve had a bunch of questions about the operation of air compressor pressure switches here at About Air Compressors. As a result, there are a number of pages about compressor pressure switches, their problems, and their remedies. Here are a few:

Run Central Pneumatic 67708 compressor without pressure switch?

Fenwai pressure switch rebuild information

Plastic hose from pressure switch keeps blowing out – how to solve?

Broken Compressor Pressure Switch Manifold – advice

Replacement of bad pressure switch on Speedaire compressor – guide

Husky VT6311403 AJ has 220 volts on pressure switch?

Sourcing Replacement Pressure Switch E247030

Replacing Compressor Pressure Switch Spring Guide With Photos

Compressor Pressure switch adjustment guide

Complaint about Campbell Hausfeld pressure switch

Pressure switch contacts keep burning out

Sourcing Replacement Pressure switch for my CP 40400

Model 47065 pressure switch leaking

Makita MAC700 Sunny pressure switch won’t turn on

Porter Cable C2002 Type 7 pressure switch problem

Sears air compressor pressure switch issues

Bostitch compressor pressure switch problems

Line Comes Off The Pressure Switch

Where is Emglo compressor pressure switch?

This page is about identifying your compressor pressure switch, understanding the operation of the pressure switch (what does an air compressor pressure switch actually do?!), and some basic troubleshooting techniques for compressor pressure switches.

Obviously, if your particular issue or query is addressed in the above list of links, feel free to take a look around for some specific pressure switch advice!

What is an Air Compressor Pressure Switch & How Does an Air Compressor Pressure Switch Work?

A pressure switch for an air compressor is simply a device that reacts to the changing air pressure in a system and either opens or closes a circuit to cause an action in response to the changing pressure in the system.

As it reacts to the pressure change in a compressed air system, the pressure switches either allow or drop an outgoing signal that is used to initiate an action.

In the case of our air compressor, the action is to turn on or turn off the electric motor of the air compressor.

What is an Air Compressor Pressure Switch Also Known As (AKA)

A compressor pressure switch is technically known as a “pressure switch”, however because of its function it can also be known as:

- Compressor cut-off switch

- Compressor cut-in switch

- Compressor cut-off control switch

What Does an Air Compressor Pressure Switch Look Like?

The photo below depicts one view of an air compressor pressure switch on a DIY type of air compressor. Smaller air compressors may not have a visible pressure switch, and the pressure switch on your compressor may be visible, but be of a different shape, color, etc.

The black box above contains the working components of the pressure switch, including the method of adjusting the cut-in and cut-out pressure levels of your air compressor.

The handle at the bottom front of the pressure switch with the red knob on the end is the OFF/RUN switch on this unit. Your compressor switch may vary, or you may not have a handle at all.

On the right, in the photo, you can see just the top of the tank air gauge on my compressor (with the white label on top ). This gauge shows the pressure in the tank and also shows the cut-out pressure level reached when the pressure switch shuts off the compressor and the cut-in pressure level when the switch starts the air compressor.

If you wish to explore your compressor pressure switch, and I do recommend that you make yourself familiar with what is inside, make sure first that the compressor power supply is unplugged then go ahead, and remove the cover. You want to be sure the power is off as there are live power connections inside the lid.

What’s Under the Pressure Switch Cover?

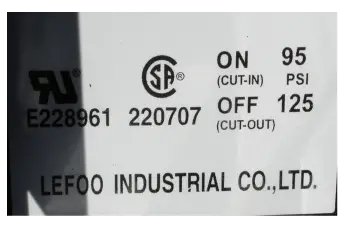

The label under the lid on my pressure switch shows the electrical certifications, the manufacturer of this switch, and also some very important information for me if I have to replace the switch, and that is the cut-in and cut-out pressure levels for this switch.

Not shown on my photo, but also on a label under the cover, is an electrical schematic of the switch which you can refer to in the event you have pulled all the wires without marking them for re-wiring of the new switch.

I expect that your switch will likely have this information under the lid too.

More Photos Under The Compressor Pressure Switch Lid

This next photo shows the wiring of my compressor pressure switch, and also the sealant-smeared adjustment nuts.

There are two nuts buried in sealant, one on each side, and one of them is to adjust the high-pressure cut-out, and the other the low-pressure cut-in.

You will not normally need to try to adjust the pressure settings of your pressure switch. The settings are properly set at the factory for the correct operation of your air compressor, and there is little to be gained by messing with them. Unless, of course, you buy a replacement pressure switch for a burned-out one, and have to set the proper cut-in and cut-out levels for your compressor.

You can see that the sealant on the adjustment nuts on my compressor is pristine, and it will stay that way. If I have a pressure switch problem, then I will simply replace the switch.

The cut-out and cut-in pressure levels of this air compressor are satisfactory for my needs, otherwise, I would have purchased a compressor with higher or lower pressures.

Again, you do want to know what your present compressor pressure switch settings are. In the event you replace your pressure switch with an after-market unit, you may have to reset that new one to match the original settings.

On many air compressors, the unloader valve is typically located on the side of the pressure switch and it is activated by the cycling of pressure switch points as they open to stop power flow to the motor circuit, and close to resuming power to the motor.

Other pressure switches have an internal unloader that is connected to the tube from the tank check valve by a fitting on the underside of the switch.

The Compressor Unloader Valve

In the photo, you can see the brass-colored unloader valve on the side of the pressure switch.

This type of unloader valve is toggled by a lever that is protruding from the side of the switch. That lever moves up and down as the pressure switch trips on and off, and in so doing, operates the unloader valve actuator by depressing or releasing the pin, which can be seen protruding down from the bottom of the valve.

This page provides detailed information about the compressor Unloader Valve.

Troubleshooting an Air Compressor Pressure Switch

If you’re not sure if your compressor pressure switch is working, the first thing to do is unplug the air compressor, pull the cover, and then bleed all the air out of the compressor tank. If the pressure in the tank is higher than the cut-in pressure of the switch, the switch will not trip. As the pressure drops it will reach and lower past the cut-in pressure of that switch, and you should be able to see and hear the switch trip.

If the pressure in the tank is below the normal cut-in, then plug the compressor in, and use a multi-meter to check and see if the voltage is flowing through the switch to the motor. If there is no pressure in the tank, the switch should have tripped to ON, and power should be flowing. If it is not, then perhaps the pressure switch is pooched (broken!).

There are a couple of issues with compressor pressure switches that are common problems regardless of the brand of air compressor they are installed on.

One of those problems is often confused with an air compressor pressure switch or an unloader valve leak. In the event your compressor pressure switch or unloader valve is bleeding air constantly, the problem may not be either. The compressor check valve may be the issue.

Read about leaking unloader valves on the pressure switch and how to fix them on this site.

If you are still having trouble with your compressor pressure switch, there is a pressure switch troubleshooting page that has lots of postings from folks who have a compressor switch problem, a lot of advice you can read and comment on, and a place for you to post your own question if the answers there do not suffice.

If you diagnose your compressor pressure switch as having failed, see the page on this site about selecting a new one.

Buying an Air Compressor Pressure Switch

While at first glance buying a compressor pressure switch can be intimidating, breaking what you need to know to do so into bite-sized chunks will make it easier for you to buy the right replacement compressor pressure switch for your make and model of air compressor.

Buying a compressor pressure switch is often a problem if the compressor is old and no OEM parts are available. Even if the air compressor is relatively new so many compressors available today have no spare parts available at all.

Yet, since the compressor pressure switch simply turns the electric power supply to the compressor motor ON and OFF based on the pressure in the compressor tank, pressure switches for compressors with electric motors pretty much all work in a similar fashion. You just have to get the one that fits your air compressor. Here’s how!

The first step is to look at the existing pressure switch to see if there is a name or model number anywhere on it. The top of the pressure switch cover may have a name. A name and model number may also be on a label inside the cover. Please make sure that the power to the compressor is disconnected before removing the pressure switch cover. Did you find a name or model number? If so, Google that, and see if what pops up looks like your switch.

No luck with that? No worries. Here’s how to carry on buying a compressor pressure switch.

If you simply Google “compressor pressure switch, you will find many different shapes, sizes, and functions.

The things you will want to look for in a new, replacement pressure switch are:

What’s The voltage of your air compressor?

When buying a replacement compressor pressure switch make sure the pressure switch you select has the same voltage as your compressor.

In North America, if your compressor is plugged into a standard wall socket, then the voltage is 120 VAC. Some really small air compressors may have a transformer to convert 120 to 12 or 24 DC, but other than tire inflators, that’s not that common.

Usually, a compressor with a higher voltage than 120 VAC will have special wiring possibly including a control panel of some sort.

The switch voltage may not be a big issue anyway as many of the modern compressor pressure switches are rated for both 120 and 240-volt power supplies. Just check to be sure what the voltage of your compressor is, and make sure that the switch you buy is rated for the same voltage or a range of voltages that includes that of your existing compressor.

What is the pressure range?

The pressure switch turns the power to the compressor motor on and off. It does this by having pressure settings at which the switch opens to stop power flow, and closes to allow power flow to the compressor motor.

The pressure point at which the pressure switch allows power to flow to the motor is the cut-in pressure setting. The pressure point at which the pressure switch stops power flow to the compressor motor is the cut-out pressure setting.

Your old switch may have had a cut-in of 90 PSI and a cut-out of 120 PSI, for example. If you cannot remember the settings, look under the cover of the old switch, or in some cases, on the cover, for the cut-in/cut-out info. Or, check the compressor manual.

You need this information to obtain a new pressure switch that has either the same pressure settings as the old one or one that has adjustable pressure settings so that you can set the new switch to the old settings. Do NOT vary the settings on the new switch by more than 5 PSI if you are setting them. The compressor is designed to be run within certain pressure ranges, and allowing pressures outside of those ranges can be hard on the compressor or result in a dangerous component failure.

The compressor pressure switch mounting?

The pressure switch must be able to “see” the pressure in the compressor tank. Therefore it will be mounted so that an airline connected to the tank will enter the pressure switch.

External compressor pressure switches typically have a threaded port in the bottom into which an airline is threaded. Some pressure switches have multiple ports. Some are bolted to a manifold or threaded onto a pipe in a manifold.

Mounting the pressure switch on the compressor can be accomplished in many ways. Carefully examine how the pressure switch is mounted on your compressor as you will need to select a replacement that mounts the same way.

This pressure switch has a base with multiple outlets. All of the outlets connect to the pressure switch, so which of these ports is plumbed to the compressor tank is immaterial. If this switch fits your compressor by using one of the holes in the base, if the pressure range is correct or adjustable, and the voltage is correct (this one is 120 VAC and 240 VAC) then this switch might work on your compressor. Unused ports in the base are plugged.

What are these things hanging on the side of my compressor pressure switch?

Have a look at the pressure switch in the photo above. It shows a red-handled ON/OFF lever on the left of the photo. Does your existing pressure switch have one of these?

Since I pull the plug on my air compressor after every use and since the ON/OFF lever or switch essentially does the same thing – cutting the power supply to the pressure switch – I really don’t see the need to have an ON/OFF switch on my compressor pressure switch too.

If I were replacing my compressor pressure switch, I’d simply skip the ON/OFF lever. But… to make it easier for you, if your present switch has an ON/OFF lever (or similar) and you are not comfortable with changing the setup on your compressor, best to get one that’s exactly the same. They are common and readily available.

Now, when you Google compressor pressure switches, you can skip all of the ones you see that do NOT have an ON/OFF lever or switch like yours.

What about the unloader valve?

Now let’s talk a moment about the other thing that is commonly hanging on the side of, or found inside of, the typical external pressure switch. That is an unloader valve. If you aren’t sure about what they do, see the information page on this site for complete details about what they are and what they do.

If your present pressure switch has an unloader valve located on the side of the switch like, or similar to, the one shown in the photo above, you must acquire a replacement pressure switch that has the same type of unloader valve on the same side of the pressure switch as yours.

Otherwise, you will be unable to install the replacement, or… and this is the voice of experience talking… you will spend an inordinate amount of time, bust a few knuckles, and turn the air blue as you try to fit the square peg into the round hole!

Internal Unloader Valve

Just to make things a bit more complex, a pressure switch may have an internal unloader valve. How do you tell if yours is one of these?

If you have not removed your existing pressure switch from your compressor as yet, look under it, and see if there is an airline plugged into the bottom of the pressure switch. The airline may use a fitting like the brass-colored fitting one in the photo above, or, it may be what is known as a “quick connect” fitting. That’s fitting with a hole in it into which you push the air tube.

Typically, the airline connected to the bottom of the pressure switch unloader runs from a fitting in the tank. This is also where the line from the pump head is connected to the tank.

Once again, you need not get an exact replacement for your compressor pressure switch if you are comfortable modifying components. Otherwise, when selecting your replacement switch, make sure you get one with an unloader port at the bottom of your new switch if there is one in the old.

How do the wires connect through the pressure switch cover?

This next photo has a red box drawn around the point where, on this switch, the cables enter the switch.

There are two “cables” that connect to a typical switch. One is the power supply cord or cable which has the plug on it, and the other is the cable or wires that go from the pressure switch to the motor circuit on the compressor.

When you look at your existing pressure switch, how is the power supply cord getting through the pressure switch cover? How are the wires going to the motor from the pressure switch exiting the pressure switch cover? Are the wires on your existing pressure switch passing through “strain relief” connectors like the one shown in the photo above?

While strain relief connections are not specifically required, they are useful if circumstances result in the power cord ever being pulled aggressively away from the compressor, like, you forget to unplug it and roll the compressor away to a new location. Just make sure that you know how the power supply to the pressure switch and from the pressure switch to the motor can get through the pressure switch cover on the new model.

A brief recap of buying a new pressure switch for your compressor

In order to buy a new pressure switch, you need to know:

- check to see if there is an existing make and model number on the switch to make finding a replacement easy

- what the compressor voltage is

- what the pressure range of the old switch was

- how the existing switch is mounted onto the compressor

- whether the old switch has an ON/OFF lever or switch

- whether the old switch has and external or internal unloader valve

- how the power supply gets into the pressure switch and from the switch to the motor circuit

Answer all of the above and then Google compressor pressure switches and find one that’s convenient to obtain and one within your budget.

One more thing…

I can’t find the compressor pressure switch?

Fractional and small air compressors that have a tank have a pressure switch. Bet on it.

Those pressure switches will not look anything like those you’ve seen so far. This picture shows another type of compressor pressure switch.

Below are two more. The one on the photo on the right is, too, often found in smaller air compressors.

Where is this one located? When you pull the cover off your small compressor, look for the ON/OFF switch. See the power line coming in from the plug? Follow the wire on the other terminal. It will normally go to the pressure switch.

Remember, all compressor pressure switches do the same thing so when trying to buy a replacement pressure switch, find a switch online that looks similar to the existing switch including any unloader valve and connections, one that has a comparable pressure range between the OFF / ON settings, has the same voltage and odds are good it will work just fine.

Still have Compressor Pressure Switch Issues?

Does your air compressor have pressure switch issues? Here’s where you can find some help dealing with them.

Many times folks think that their compressor may have a pressure switch problem since air leaks out the pressure switch when the compressor is stopped is common. And that’s the pressure switch, right? Nope. That is not necessarily a pressure switch issue.

If that is the symptom you are trying to resolve, you likely need to clean or replace the air tank check valve.

A lot of folks have other compressor pressure switch problems and have sent in questions that I have tried to answer. Hopefully, the above questions and answers have been useful in helping you solve your air compressor pressure switch issues.

Add your own question if you cannot find an answer in the existing comments,

If you read a question on which you can provide some advice, please add it as a comment. Then all can benefit from your compressor experience.

Thanks very much.

Bill

FAQs (Frequently Asked Questions)

Most air compressor pressure switches are universal, and they will specify that they are. Some pressure switches however may be designed specifically for certain models or make of air compressors.

To wire a pressure switch on a 240v compressor you will first need to ensure the circuit breaker is turned off before identifying the cords and terminals on the switch. You may then go ahead and attach the cords to their terminals before restoring the circuit breaker. This is of course simplified, and for a more detailed guide, visit here!

The first step is to turn off the circuit breaker before starting the wiring process. You then need to identify the cords and terminals before you can attach the cords to their terminals and finally restore the circuit breaker. For more detailed information, visit our guide here!

To select the right pressure switch for your air compressor, you should pay close attention to the cut-in and cut-out pressure, and whether the switch is then fixed at these points or is adjustable. Ensure that the switch has a maximum pressure well above your compressor’s operating pressure and that it can handle the electrical load.

Additional Troubleshooting Pages

Air Compressor Types Troubleshooting

- Centrifugal Air Compressor Troubleshooting

- Rotary Vane Air Compressor Troubleshooting

- Rotary Screw Air Compressor Troubleshooting

- Reciprocating Air Compressor Troubleshooting

- Scroll Air Compressor Troubleshooting

Air Compressor Part Specific Troubleshooting

- Air Compressor Troubleshooting, Solutions, Common Problems & Causes

- Air Compressor Check Valve Troubleshooting

- Air Compressor Electrical Troubleshooting

- Air Compressor Pressure Regulator Troubleshooting

- Air Compressor Reed Valve Troubleshooting

- Air Compressor Smells Like It’s Burning? Troubleshooting Compressor Burning Smell

Related Articles Worth a Read!

How to Adjust The Air Compressor Pressure Switch

Have a question or trying to troubleshoot a compressor pressure switch issue?

Post it below and add photos please.