I have received enough requests for help from folks who complain that they “get no air out of hose” from their compressor that I thought it was time to have a page on the subject. Below are some hints about a few things to check. Please review them to help solve the problem. No solution found? Leave a post at the end of the page.

Table of Contents

- Is There Air In The Compressor Tank?

- Is There A Pressure Reading On The Regulator Gauge?

- Can the regulator handle be turned

- Is The Discharge Coupler Creating Some No Air Out Of Hose Issues?

- A Matching Connector Is Required

- Plugged Air Line

- Still No Air Out Of Hose?

- One More Thing To Check!

Is There Air In The Compressor Tank?

Is there air in the compressor tank? The tank gauge will indicate if there is air in the tank. If the tank gauge is reading zero, there is no air in the tank, and you cannot get the air out of the airline.

If so, start the air compressor and let the tank fill to cut out. Check if you now have air out of the hose. If not, please read on.

Is There A Pressure Reading On The Regulator Gauge?

Unless a large piece of debris (very unlikely) blocks the pipe out of the tank, it is reasonable to assume that air is getting to the air regulator, which will typically be the first piece of equipment in the discharge line from the compressor tank.

Actually, the air flowing from the tank should be run through a compressed air filter first, but I rarely see a filter on a DIY-type air compressor.

Most air compressors have two gauges. One is your tank air gauge referred to earlier, and the other is the one that displays the air pressure setting on your compressed air regulator.

If the tank air gauge shows air pressure, so should the gauge on your regulator. They may not show the same pressure, though, depending on the pressure level in the tank and the pressure setting of the air regulator.

Please see the regulator information page on this site for details about regulator operation if you need a bit of help with what they are and how regulators work.

If there is no air pressure showing on the regulator gauge, and there is air pressure in the tank, then it is possible that the regulator adjustment knob has been turned completely down to zero, effectively shutting off the compressed air flow. If this is the case, the compressed air supply in the tank cannot reach the regulator to alter the regulator gauge display.

Can the regulator handle be turned

Turn the adjusting knob (some need to be pushed up or pulled down to connect) until you see the pressure level display on the regulator gauge change. Continue turning in either direction until you get the desired downstream pressure level on the regulator gauge. This setting will be the pressure that your downstream air tool will see.

That regulator setting cannot be higher than the existing tank pressure level. If there is no air in the tank, you cannot visibly adjust the regulator, though you can turn the adjustment knob. You will not see any change in the regulator gauge.

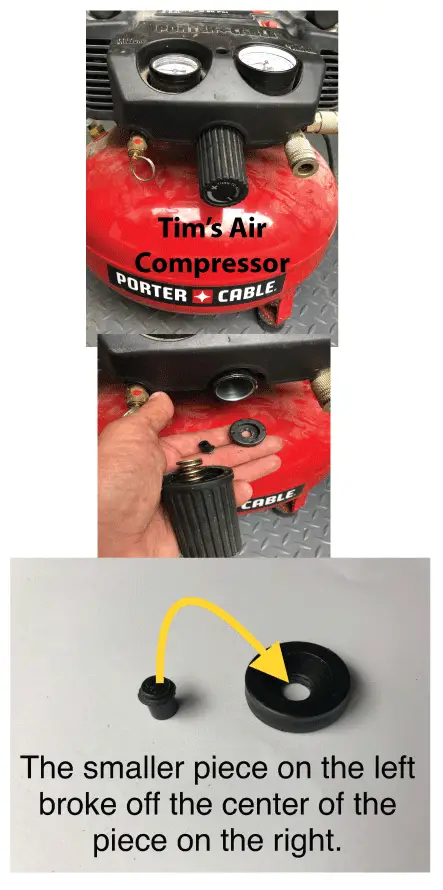

There is another real possibility the compressor regulator can cause no air out of hose! I am grateful to Tim Buckle for providing the following photos of the regulator on his compressor, which was the cause of no air out of the hose on his machine.

Is The Discharge Coupler Creating Some No Air Out Of Hose Issues?

So far, we have identified that we have air in the tank. If there was no tank pressure, we ran the air compressor to cut out pressure, and the compressor stopped.

We should now have an air pressure setting on the regulator gauge, indicating that the regulator is open and air can flow to the discharge coupler. Now we want to check this, as it is the place into which you plug your air hose.

Please see the page on compressed air couplers if you want to have better understanding of what they are and how they work.

When plugging a connector into the discharge coupler, is air flowing through the coupler into the air hose?

Turn the pressure down to about 5 PSI on the regulator.

Look inside the open end of the discharge coupler. At the very back of the coupler orifice, there should be part of a ball check visible right in the middle of the back.

With safety goggles on, and very carefully, insert a small blunt object (pencil perhaps) to push on and unseat the ball; check inside and at the back of the coupler. Does air flow out when you do this?

If air flows out, then you now know that air is getting out of your air compressor properly, if not down the air line.

A Matching Connector Is Required

The discharge coupler will only flow air properly when it has a matching and mating connector (see connector page for more info if needed) inserted into it.

Inserting the correct connector unseats the ball check fully and locks the connector and coupler together at the same time.

If you insert a non-matching connector into the coupler, the connector might still lock into place, but it also may not unseat the ball check fully, and little or no compression will flow. Make sure that the coupler and connector match.

Plugged Air Line

At this point then, you should have compressed air flowing out of your compressor, through the discharge coupler, through the connector, and into the airline.

The air line will pressurize, but air typically will not flow out the other end, because it too should have a checked coupler on the end of the air line. You can tell when an air line is charged with air, simply by watching it as you plug in the connector. The line may swell a bit, unkink a bit, and might even straighten out the coils a bit as the I.D. is pressurized.

Then, you plug the connector from your air tool or air appliance into the coupler at the end of the air line, and you should have air flowing into the air tool or air using appliance.

Still No Air Out Of Hose?

Make sure that the air hose is not lodged under something, a car tire, for example. That wouldn’t be the first time that has happened.

Also, ensure the air tool connector matches the air hose’s coupler. If you do not have air flowing out of the hose at this point, please visit the ASK page, tell me what steps you have taken, and I will see if I can help further.

One More Thing To Check!

Recently, a visitor wrote about this issue, and it turned out that the new one worked fine when they tried another air tool.

The problem was the original air tool hadn’t been used for some time, fresh lubrication was not applied, and basically, the vanes inside the tool were stuck. So, swap air tools and make sure, will you?